I figured I would start somewhat of a build thread, though with no real target or end goal as that is still evolving.

Some initial considerations for my ideas:

- Large locomotive capacity such as longer 6 axle units (SD70, SD60, GE ES44DC, etc)

It looks like a 15" minimum turn radius would be a good idea. I have seen as wide as 18" recommended and some say never, on any layout, go below 11".

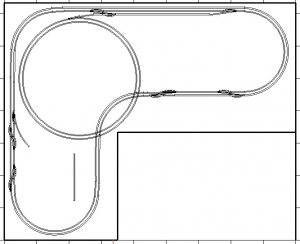

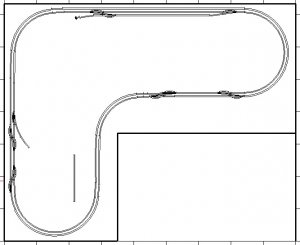

- Double main line loop with turn outs to cross between

- DCC control, wireless

- Mountain scene

- Staging area with closed loop, split off access run off main line to access - not direct off the main line loops

- Lots of elevation changes, possibly a mountain loop on top with intricate gorges and tunnels, though I'd like tunnels on the main line.

- Modular design for moving/portability

- Flowing water?

It seems era is a common defining point. I would say modern. I don't have any particular era going back in time that I would want to specifically model. Though, I do like steam locomotives. From a scale perspective I wouldn't be too concerned with steam being out of place with a modern layout. Maybe I could do a nostalgic steam passenger train at some point. I have several steam locomotives, but I think most of them are HO. I don't know if I have one for N yet. I have to dig out my train stuff from my parents basement... all I have right now is some of my O27 and HO, N is still MIA.

I am pretty sure the track I have is all Code 80. I don't think I have many, if any, turn outs yet.

Some initial considerations for my ideas:

- Large locomotive capacity such as longer 6 axle units (SD70, SD60, GE ES44DC, etc)

It looks like a 15" minimum turn radius would be a good idea. I have seen as wide as 18" recommended and some say never, on any layout, go below 11".

- Double main line loop with turn outs to cross between

- DCC control, wireless

- Mountain scene

- Staging area with closed loop, split off access run off main line to access - not direct off the main line loops

- Lots of elevation changes, possibly a mountain loop on top with intricate gorges and tunnels, though I'd like tunnels on the main line.

- Modular design for moving/portability

- Flowing water?

It seems era is a common defining point. I would say modern. I don't have any particular era going back in time that I would want to specifically model. Though, I do like steam locomotives. From a scale perspective I wouldn't be too concerned with steam being out of place with a modern layout. Maybe I could do a nostalgic steam passenger train at some point. I have several steam locomotives, but I think most of them are HO. I don't know if I have one for N yet. I have to dig out my train stuff from my parents basement... all I have right now is some of my O27 and HO, N is still MIA.

I am pretty sure the track I have is all Code 80. I don't think I have many, if any, turn outs yet.

Last edited by a moderator: