I'm pretty new to this decoder installation subject, and I have a particular installation problem.

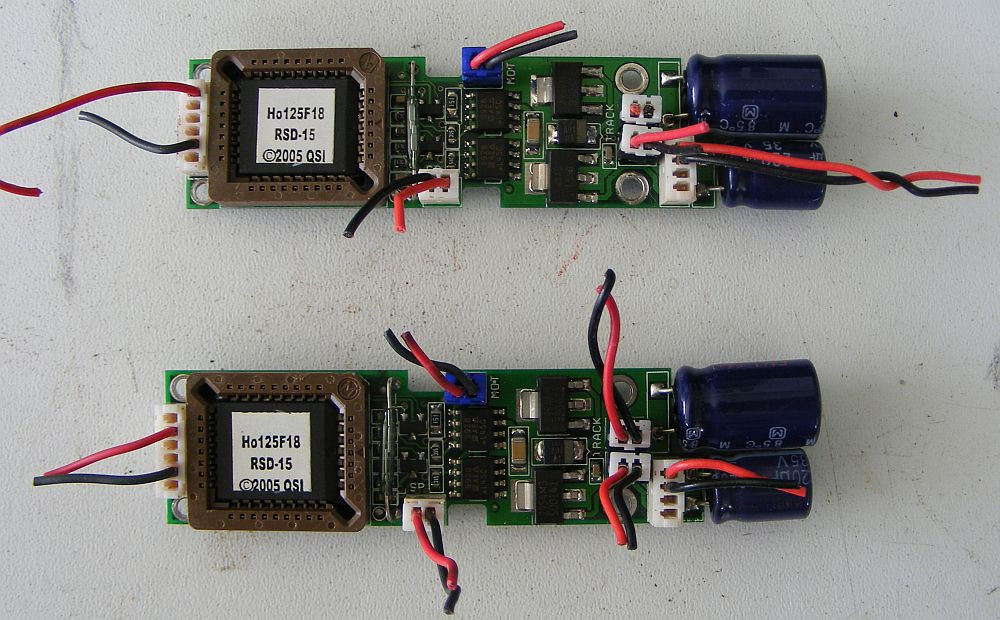

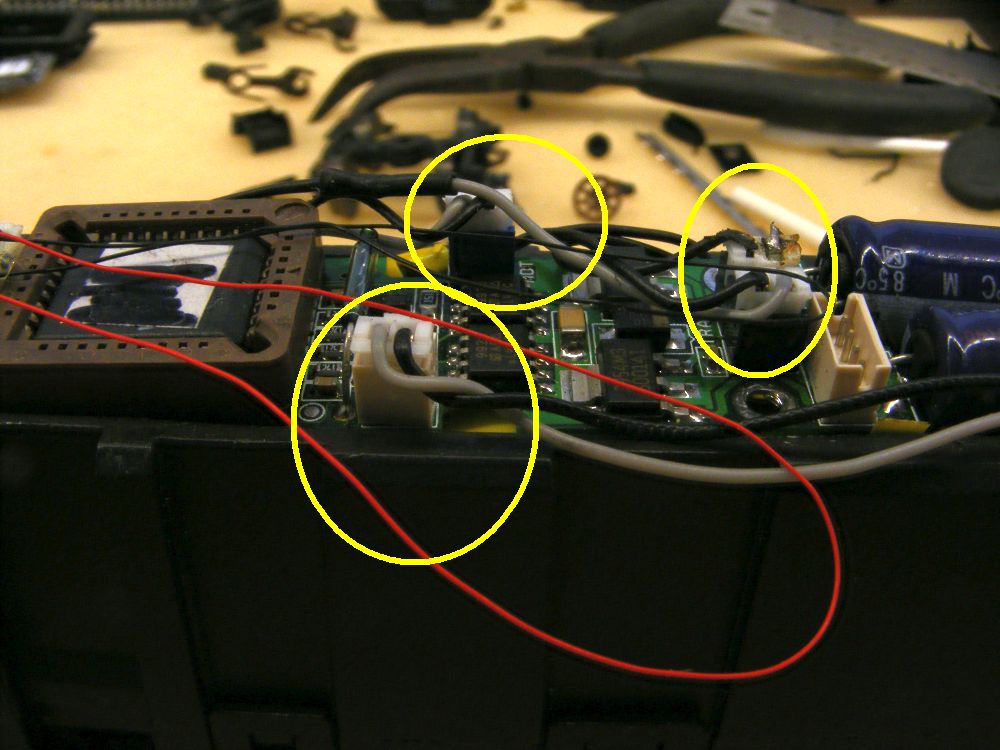

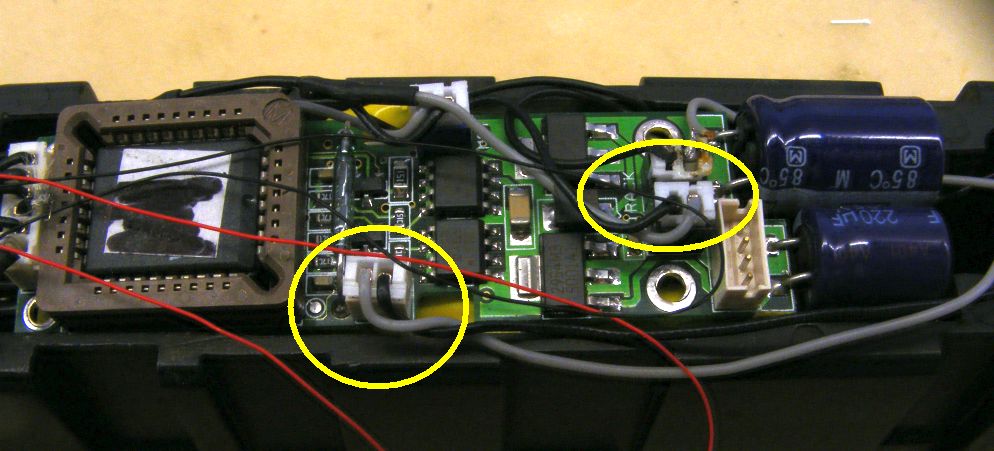

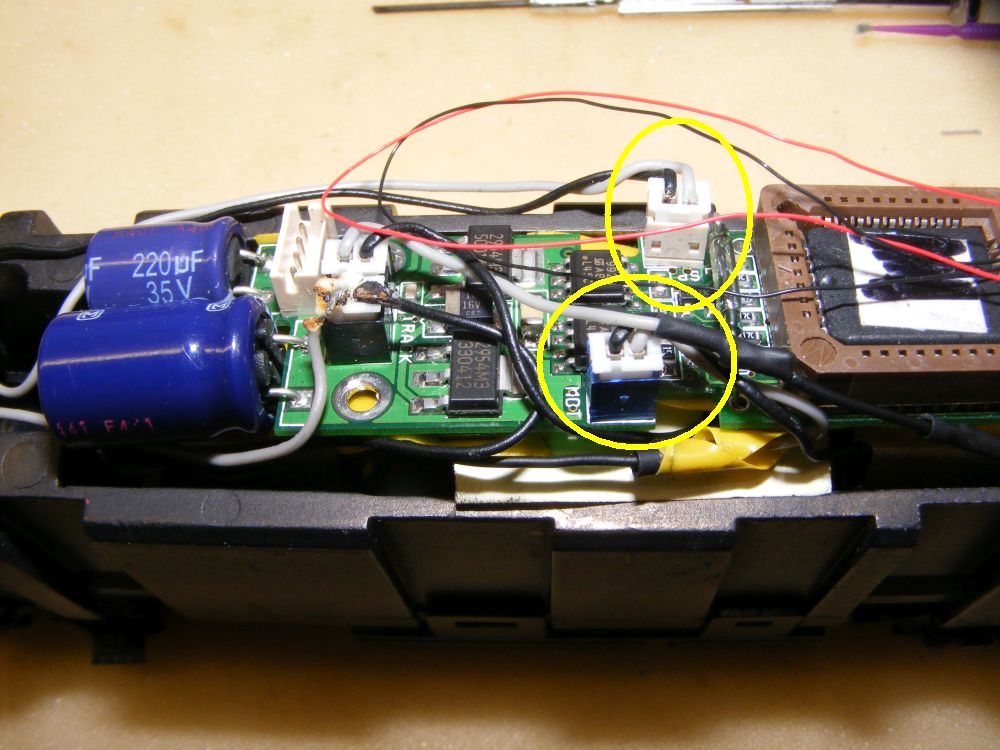

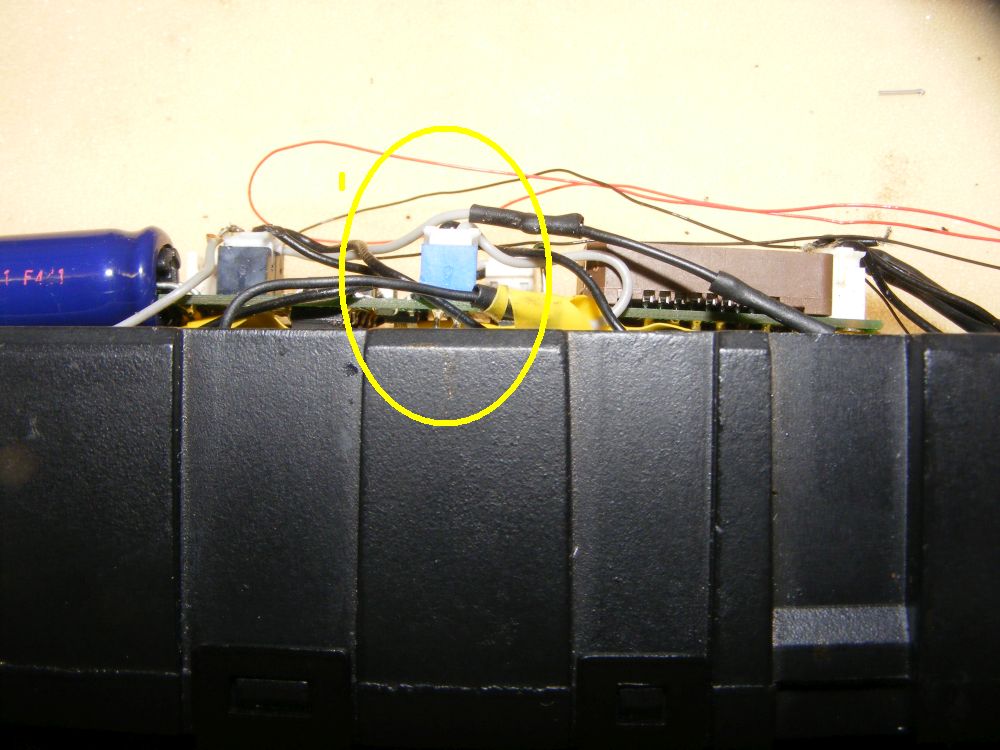

I'm removing the decoder/electronics board from a BLI F7 loco that developed zinc pest, and hoping to install it into an Intermountain F7 chassis. The problem that has arisen is that a number of those wire connectors that plug into the mother board (circled on the photos) are just slightly too tall to fit under the shell, Can they be replaced by a different type connector, OR solder directly to the board?

I'm removing the decoder/electronics board from a BLI F7 loco that developed zinc pest, and hoping to install it into an Intermountain F7 chassis. The problem that has arisen is that a number of those wire connectors that plug into the mother board (circled on the photos) are just slightly too tall to fit under the shell, Can they be replaced by a different type connector, OR solder directly to the board?