I'm at the point in my layout where I have to design a decent control panel. You can see what I'm doing here: http://www.modelrailroadforums.com/forum/showthread.php?34159-The-Saanich-Peninsula

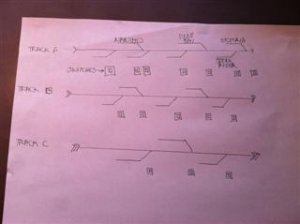

As I have three separate railroads on my layout, and I'm doing this on the cheap, I'm using three little transformers (two Bachman, one Lifelike), all of which came as part of job lots. I put together a little box that holds the transformers and the four turntable switches, but I've decided that as four of my turnouts (points, switches, what do you folks prefer?) can't be reached from the front of the layout I might as well electrify all 13 turnouts. I've been looking at control panels on various websites, and I've found lots of instructions on how to transfer patterns, and cut plexi, and how to wire little lights to tell me which turnout is in what position, but I haven't found any pictures of a panel with three transformers and 20 switches, or even anything approximating that. I can design my own, and I will if need be, but if someone else has an elegant solution I see no need to reinvent the wheel. Any suggestions appreciated.

As I have three separate railroads on my layout, and I'm doing this on the cheap, I'm using three little transformers (two Bachman, one Lifelike), all of which came as part of job lots. I put together a little box that holds the transformers and the four turntable switches, but I've decided that as four of my turnouts (points, switches, what do you folks prefer?) can't be reached from the front of the layout I might as well electrify all 13 turnouts. I've been looking at control panels on various websites, and I've found lots of instructions on how to transfer patterns, and cut plexi, and how to wire little lights to tell me which turnout is in what position, but I haven't found any pictures of a panel with three transformers and 20 switches, or even anything approximating that. I can design my own, and I will if need be, but if someone else has an elegant solution I see no need to reinvent the wheel. Any suggestions appreciated.