I just purchased two sets of these container cars.

https://www.walthers.com/thrall-5-u...un-ttx-dttx-740428-large-black-and-white-logo

I was rather pleasantly surprised that they turned out to have metal frames/bodies. My thought was that these should track VERY well even in an empty state.

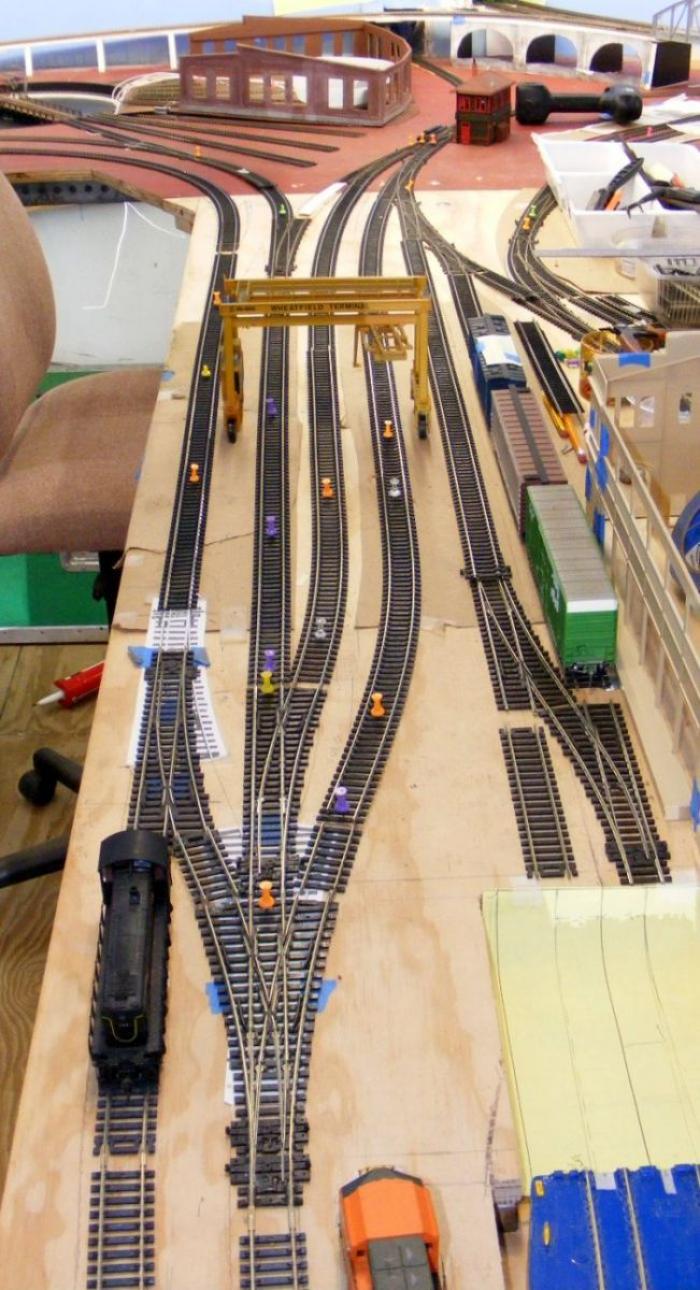

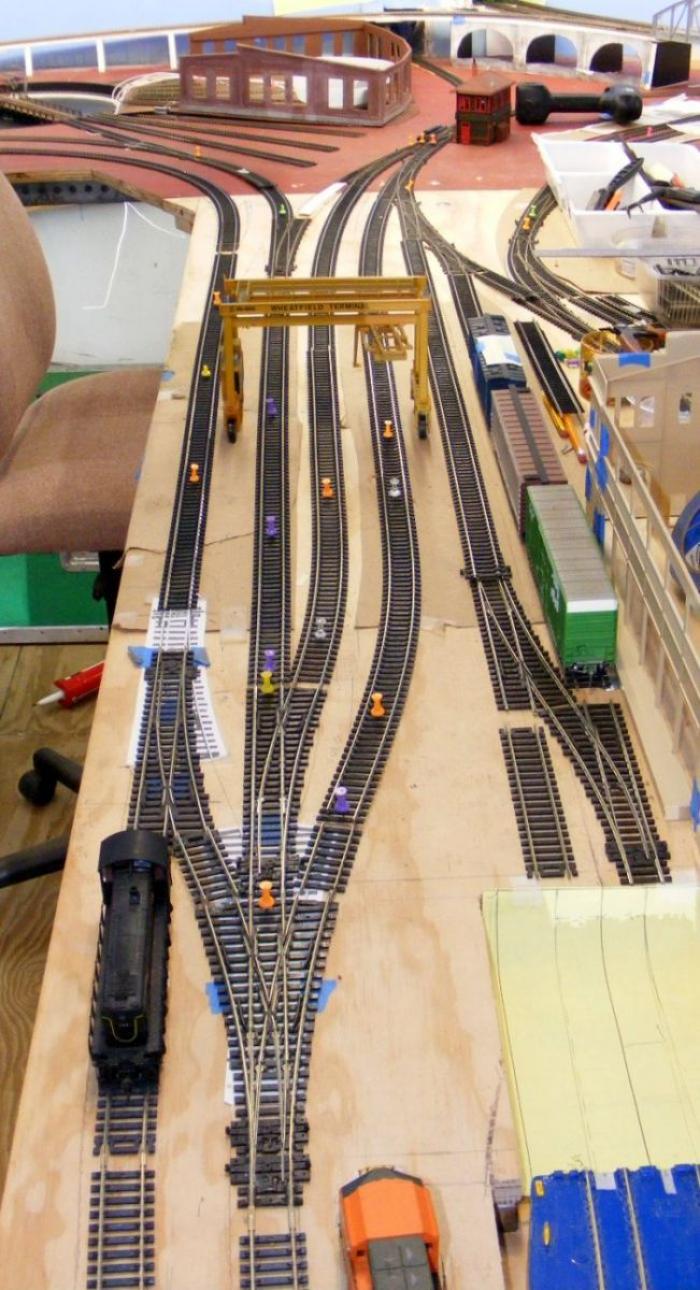

I decided to give them a little test on my peninsula container yard track. I hooked up two together and ran them by hand thru the end of the yard with a 3-way Peco turnout at its end,...

I was totally surprised at the multiple derailments that occurred with the wheels of the shared truck between the 2 cars,...and mostly when I was pushing them thru in the diverging track direction. Surely the short length of these cars, and their heavy weight would have prevented this? And after all,.... my 48' plastic framed container cars did NOT seem to have any such problems??

As I investigated more closely I determined that the nice metal wheels and trucks of the trucks trailing the first truck were actually picking the frog point of that 3-way turnout. Adding some weight (or extra downward pressure) did not always alleviate the situation (as John Garity has noted on another forum).

One solution that appeared to help was a slight loosening of the truck screw on the one that appeared to want to climb the frog point. That helped,...but I fear is not the ultimate solution.

I think the best solution is going to be the shimming of that guard rails across from the frog. These Peco turnouts just have too wide of a slot there as has been discussed in a number of other threads. The slightly tighter slot keeps the truck from picking the frog point.

So I have decided to shim all of my Peco 3-ways,...I have a total of at least 5 Peco ones on my layout, and at least 3 Roco ones. (the Roco ones have not presented themselves as a problem yet).

I underlined that posting above as I believe the adjustment of the truck screw might have as big a detrimental effect as the too-wide slot in the turnouts.

I'm now thinking that these new container cars that I had received came with their trucks rather tightly bound up from their factory assemble process,..and thus needed to be loosened up a little on one end, ....the coupler end in particular, as the other end is riding on that fixed pivot pin.?

When I loosened up on that truck's screw it made things a lot better. It made me think this idea might just be applicable to other container cars we might purchase new,...some fine tuning.

Anyone else experience such a problem with container cars?

https://www.walthers.com/thrall-5-u...un-ttx-dttx-740428-large-black-and-white-logo

I was rather pleasantly surprised that they turned out to have metal frames/bodies. My thought was that these should track VERY well even in an empty state.

I decided to give them a little test on my peninsula container yard track. I hooked up two together and ran them by hand thru the end of the yard with a 3-way Peco turnout at its end,...

I was totally surprised at the multiple derailments that occurred with the wheels of the shared truck between the 2 cars,...and mostly when I was pushing them thru in the diverging track direction. Surely the short length of these cars, and their heavy weight would have prevented this? And after all,.... my 48' plastic framed container cars did NOT seem to have any such problems??

As I investigated more closely I determined that the nice metal wheels and trucks of the trucks trailing the first truck were actually picking the frog point of that 3-way turnout. Adding some weight (or extra downward pressure) did not always alleviate the situation (as John Garity has noted on another forum).

One solution that appeared to help was a slight loosening of the truck screw on the one that appeared to want to climb the frog point. That helped,...but I fear is not the ultimate solution.

I think the best solution is going to be the shimming of that guard rails across from the frog. These Peco turnouts just have too wide of a slot there as has been discussed in a number of other threads. The slightly tighter slot keeps the truck from picking the frog point.

So I have decided to shim all of my Peco 3-ways,...I have a total of at least 5 Peco ones on my layout, and at least 3 Roco ones. (the Roco ones have not presented themselves as a problem yet).

I underlined that posting above as I believe the adjustment of the truck screw might have as big a detrimental effect as the too-wide slot in the turnouts.

I'm now thinking that these new container cars that I had received came with their trucks rather tightly bound up from their factory assemble process,..and thus needed to be loosened up a little on one end, ....the coupler end in particular, as the other end is riding on that fixed pivot pin.?

When I loosened up on that truck's screw it made things a lot better. It made me think this idea might just be applicable to other container cars we might purchase new,...some fine tuning.

Anyone else experience such a problem with container cars?

Last edited: