I plan on mounting SMD's directly to the back-sides of the factory acrylic head/tailight lenses. Should I use the largest size SMD that fits the lens diameter or should I choose a smaller size? The lenses are approx 2 mm in diameter, so 0805's might just fit with no wiggle room for the attached wires. Would going to the smaller 0603's cause any issues?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Choosing SMD type LED headlight size-Diesel Loco

- Thread starter Toolbelt

- Start date

ModelRailroadForums.com is a free Model Railroad Discussion Forum and photo gallery. We cover all scales and sizes of model railroads. Online since 2002, it's one of the oldest and largest model railroad forums on the web. Whether you're a master model railroader or just getting started, you'll find something of interest here.

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website (Learn More Here)

Colorado Midland Modeler

Proudly modeling the CM, MT & SL in HO Scale

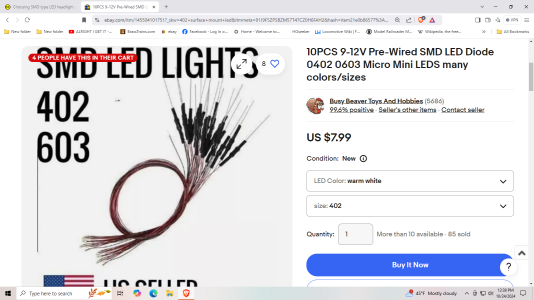

Yes, I think even the tiniest ones are bright enough and I anticipate even increasing the base resistor size to dim them further. I believe some decoders even allow you to dim them. Not sure if those decoders have built in resistors, but the dimming feature seems like a good feature, although I think once you find the right resistor based on tastes, there would likely never be a need to adjust them again.I bought these (with the advice of the fine folks on this forum) for my brass steamers, they fit in the smallest of headlight housings and are super bright. Something like them should work quite well for a diesel.

Agreed. I'm trying to train (no pun intended) myself to think in terms of scale. From a distance of 3' away, an HO scale light should be no brighter than 300' away from the real thing.Point is a small LED, such as a 402 will sufficiently light a train.

D&J RailRoad

Professor of HO

After installing it, give it a coating of liquid tape so the light doesn't fill the inside of the shell.

I had planned on using a couple of coats of flat black acrylic. Will the light bleed through that?After installing it, give it a coating of liquid tape so the light doesn't fill the inside of the shell.

D&J RailRoad

Professor of HO

I don't know about the paint but the liquid tape goes on thicker and sets up faster.I had planned on using a couple of coats of flat black acrylic. Will the light bleed through that?

The headlight leds will be mounted inside a round hole to the backside of the lens, however the numberboard leds (which will be larger to hopefully help light up the entire board, although I plan to dim them more) will be flush to the board backsides inside the cab so your liquid tape idea might solve two problems. Thanks.I don't know about the paint but the liquid tape goes on thicker and sets up faster.

Colorado Midland Modeler

Proudly modeling the CM, MT & SL in HO Scale

This should be of some help to you. The first photo shows one of the 402 LEDs compared to the tip of a pencil and CM 25's smokebox door. Next photo shows CM 25 with LED and headlight lens installed, with LED lit. The other two show my PFM Berkshire with the LED and lens with the LED lit as well. As for how to mount them, on the engines I've done so far I've tried silicone and liquid electric tape. Both work quite well, but have their own pros and cons. The silicone is easy to use, holds well and has no to little odor. But, it takes awhile to cure, and has to be painted to prevent light bleed through. The liquid electric tape is also easy to use, cures quick and strong, and doesn't have light bleed through. The bad part is it's very stinky.

D&J RailRoad

Professor of HO

Yep, basically a scale size light bulb.

There is a clear acrylic factory lens installed in the Blue Box, and my plan is just to crazy (CA) glue it to the backside, then coat it with some liquid tape, as suggested, to prevent light bleed. I realize CA is permanent, which means it will be a pain if I ever have to replace the leds, but I recon I can just drill it out from the front side and start again. The original cab toaster bulb still works after 37 years so hoping the leds will provide at least a few years.This should be of some help to you. The first photo shows one of the 402 LEDs compared to the tip of a pencil and CM 25's smokebox door. Next photo shows CM 25 with LED and headlight lens installed, with LED lit. The other two show my PFM Berkshire with the LED and lens with the LED lit as well. As for how to mount them, on the engines I've done so far I've tried silicone and liquid electric tape. Both work quite well, but have their own pros and cons. The silicone is easy to use, holds well and has no to little odor. But, it takes awhile to cure, and has to be painted to prevent light bleed through. The liquid electric tape is also easy to use, cures quick and strong, and doesn't have light bleed through. The bad part is it's very stinky.View attachment 203001View attachment 203002View attachment 203003View attachment 203004

GGNInNScale

Granite Gorge and Northern Again

I buy a bunch of 0201 and 0402 LEDs in various colors from Tayda Electronics or other eBay sources. I get SMD resistors- 1.5kOhm, 2.2kOhm and 3.3kOhm, then take the extra unused wires from decoders. I use double-sided tape on a piece of scrap wood, stick the parts down, a bit of flux, and a touch of solder on the contact pads, then put the two parts in contact and another touch of the soldering pencil in the center joint, and they are welded together. Solder two wires on the outside contacts and test with the diode mode on a DVM for polarity. The LED will light when you get the right polarity..

To light up my number boards and headlights, I ordered some warm white 0603's which I will glue directly to the back lens surfaces. The clear acrylic Blue Box factory headlight lenses allowed almost no light to pass through so I drilled them out and ordered some 2mm acrylic rods which I'll cut to length. These leds are rated 2.8-3v and 20ma. I'm going to make an assumption that these may be too bright for my tastes, so what is a good resistor value as a starting point, to dim them down a bit. I'm not familiar with the specifics of resistors and leds though I know the basics. Is between 1.5k and 3.3k ohms a good starting point for a 1990's diesel? I will be testing them out with a 3v watch battery as I don't have a decoder yet, and will adjust as needed based on decoder voltage when I get around to that phase of the project.

GGNInNScale

Granite Gorge and Northern Again

Hi If you use a 3V battery or power supply, then an appropriate resistor is 330 to 560Ohms. If you are using DC in your engines then the resistor range is 1500 to 3300Ohms. The intensity will vary a bit with speed. If you are using DCC, then wire to the appropriate contact pads on the decoder and use a resistor in the range of 1500-3300Ohms. I try to decrease the light output in most cases because the LEDs are really bright. An 0603 will throw a lot of light. I use 0201 and 0402 LEDs.

Last edited:

ok 330 to 560 ohms it is. Do the outputs on dcc systems typically put out 3v and/or track voltage or are there many variations depending on manufacturer? Is there some kind of industry standard, in other words? I won't be running this old Athearn BB on DC once I've hooked the lights up. Im working on the detailing for now and am popping the cab off to do the lighting, so it looks like the DCC phase will be the last part of the project, although obviously hooking the lights to the DCC board will be part the final touches. As a DC loco, this GP50 run/ran smooth as silk and it has sentimental value as well. So I'm trying to give her a new life and maybe even a voice depending on which DCC will work.

GGNInNScale

Granite Gorge and Northern Again

Most decoders have built-in resistors on the PCB. So, you can hook up an LED directly. I usually add a series resistor to reduce the current further- for these decoders I usually use either 1500Ohms or 2200Ohms. I have shown this a few times in other locations in this site and other model train websites. Note: I do not know all of the decoder companies- only NCE, TCS, DigiTrax, ESU and Lenz.

So decoders with built in resistors likely put out 3v at their contacts, but that output can be further reduced by adding resistors in the 330 to 2200 ohm range then? The resistors drop the current but the voltage remains 3v?Most decoders have built-in resistors on the PCB. So, you can hook up an LED directly. I usually add a series resistor to reduce the current further- for these decoders I usually use either 1500Ohms or 2200Ohms. I have shown this a few times in other locations in this site and other model train websites. Note: I do not know all of the decoder companies- only NCE, TCS, DigiTrax, ESU and Lenz.

GGNInNScale

Granite Gorge and Northern Again

Not quite. The decoders typically put out about 5V for the lights, but they have on-board resistors to limit the current and set the final voltage bias on the LEDs. An LED is what is called a "non-linear device". The current-voltage relationship is kind of like a hockey stick- current increases rapidly with voltage above the device threshold. The resistor takes some of the voltage, the rest goes to the LED. This is called a "Voltage divider", in this case a non-linear divider until the circuit settles (really fast, so you do not need to worry about this point). The key point is to put the LED into forward conduction- that is, producing light, without allowing too much current to flow.

This might help you. https://en.wikipedia.org/wiki/Light-emitting_diode

Looking at these curves, 5V would destroy all LEDs except perhaps a deep UV diode- a poof of smoke... By the way, sometimes manufacturers use colored plastic to achieve the color(s), so they only have to make one or two "colors" of LEDs.

Opinion and bias: I do not like running electronic devices near their limits. I have maintained this position since I designed my first audio power amplifiers in 1971. They would run cool even at relatively high power outputs. It adds a little cost, but the amps are still running today ( I did re-cap them about 10 years ago). I was in semiconductor research and production for about 40 years- if you have a field-failure of a part, it is REALLY costly to chase down the cause- even if it the customer's error. This expense goes right to the bottom line, hence my bias.

This might help you. https://en.wikipedia.org/wiki/Light-emitting_diode

Looking at these curves, 5V would destroy all LEDs except perhaps a deep UV diode- a poof of smoke... By the way, sometimes manufacturers use colored plastic to achieve the color(s), so they only have to make one or two "colors" of LEDs.

Opinion and bias: I do not like running electronic devices near their limits. I have maintained this position since I designed my first audio power amplifiers in 1971. They would run cool even at relatively high power outputs. It adds a little cost, but the amps are still running today ( I did re-cap them about 10 years ago). I was in semiconductor research and production for about 40 years- if you have a field-failure of a part, it is REALLY costly to chase down the cause- even if it the customer's error. This expense goes right to the bottom line, hence my bias.

So if one was to measure the voltage light output on a decoder, it would be in the 3v range after the onboard resistor but 5v before the resistor? An LED rated at 3 volts will still produce some light as the voltage is dropped below 3v, or does the voltage need to maintained around 3v but the current (Ma) is reduced by a resistor and the current is what determines brightness?

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website (Learn More Here)