D&J RailRoad

Professor of HO

I have plenty of "stuff" layin around to be creative with.

I've had this heavy duty flat car now for awhile and been wanting to put some kind of load on it. I was digging around in the junk loco box and found this geep. No decoder in it, not sure why it's in the junk box.

Well, it prolly needs to be carried to a depot repair facility.

Stripped the motor out of it. Removed the trucks and dud some fitment checks to the flat car. It's a go.

Did some checking on the internet for some ideas on how they are loaded and secured.

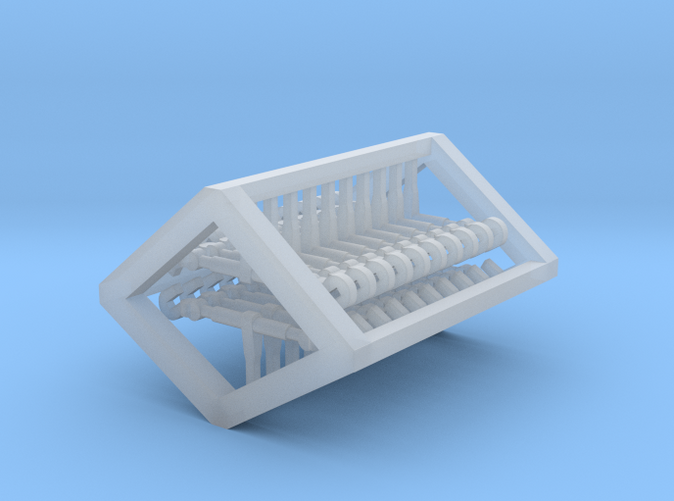

Started the buildup on the deck to support the frame. Looks like some 8x8 beams.

I've had this heavy duty flat car now for awhile and been wanting to put some kind of load on it. I was digging around in the junk loco box and found this geep. No decoder in it, not sure why it's in the junk box.

Well, it prolly needs to be carried to a depot repair facility.

Stripped the motor out of it. Removed the trucks and dud some fitment checks to the flat car. It's a go.

Did some checking on the internet for some ideas on how they are loaded and secured.

Started the buildup on the deck to support the frame. Looks like some 8x8 beams.