bshire284

New Member

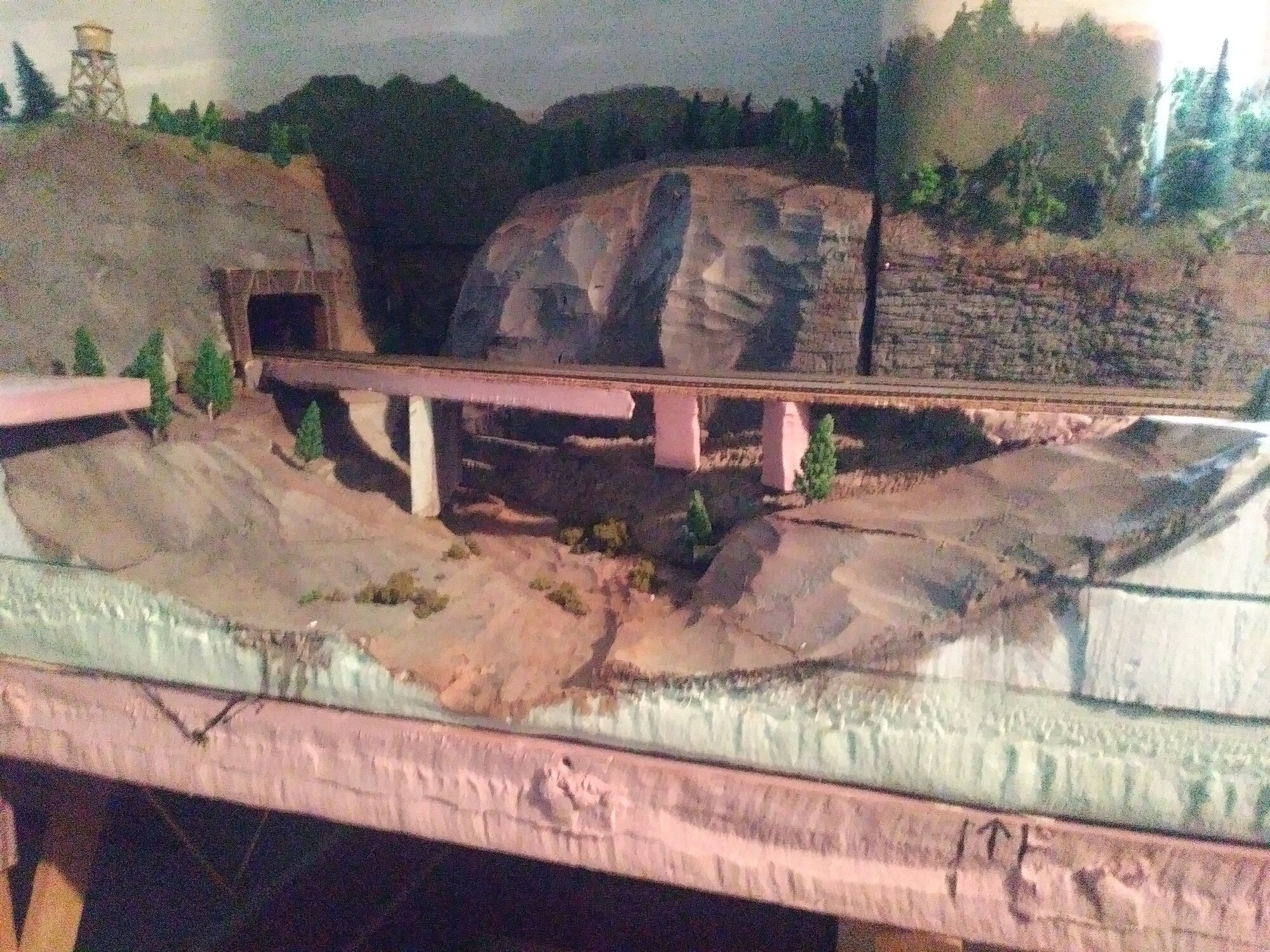

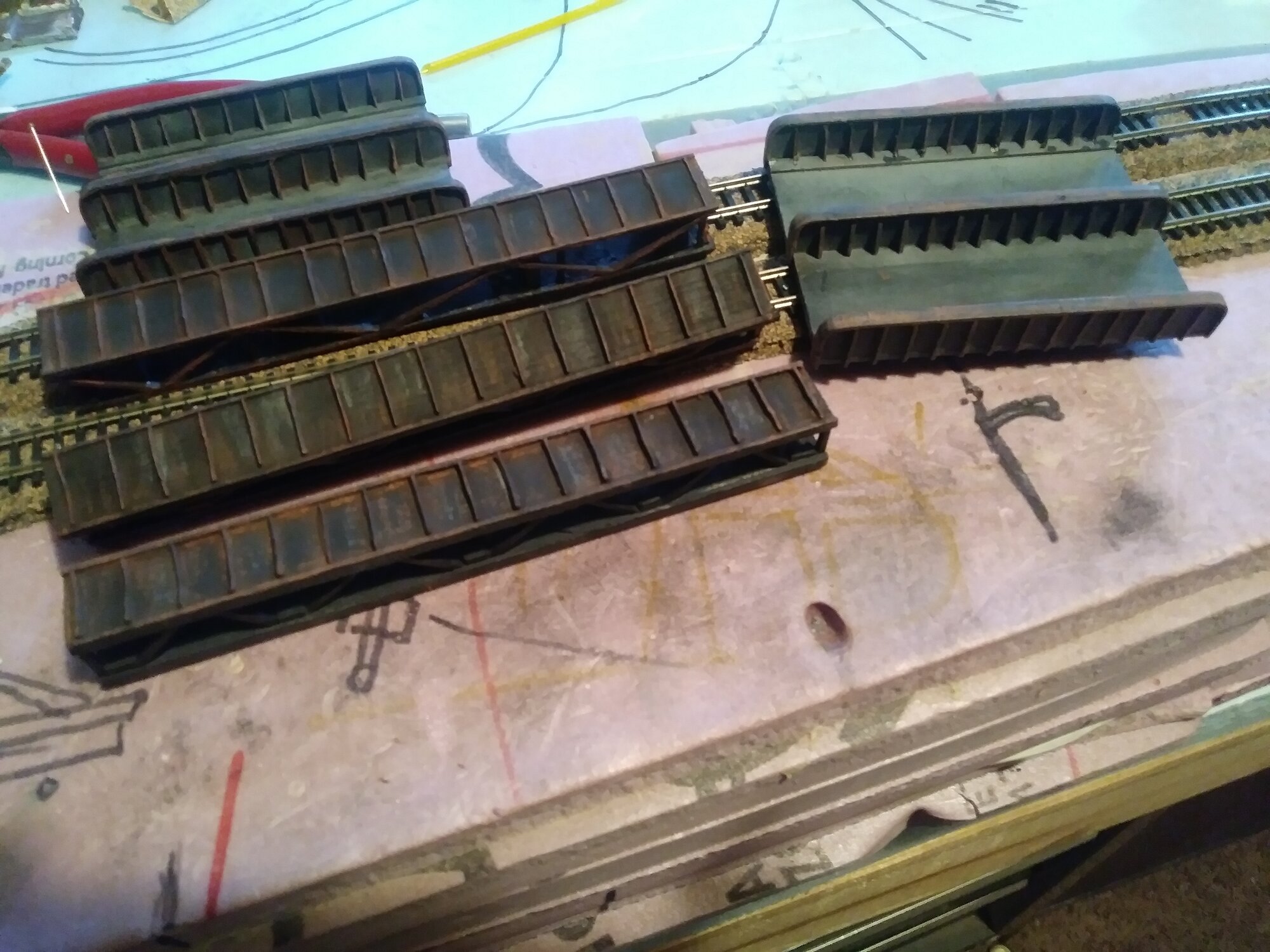

Hey folks. Long time no post. I'm modeling in the late 60's and earlier era and I need some bridges for a 220 ft. double track bridge span that typically starts (approach) at the exit of a tunnel. At the approach, I would like to use two 80' open deck bridges then onto some Warren trusses and exit onto the deck plate girders.. I'm undecided on building the OD 80'ers as a double track or 2 singles and thought I would get some opinions on this. Has anyone else used the 80' or shorter open decks as singles (open framework) on a double line or do they typically build them as doubles with ballast? This is my first attempt at using bridges on the layout so hope this makes sense and any help on this one is welcome and appreciated. I scratchbuilt some open decks and plate girders I will be using.