Well, scratch build overstates it slightly since I used some bits of caboose roof, end blocks, and freight car flooring from Northeastern Scale Lumber. The curved roof is not prototypically accurate but it is what I had on hand, so I went with it. The length is closer to 30' than the supposed 25' prototype (per https://3dptrain.com/shop/gbc-b016/ ) as well. But what fun is scratch building if you can't take some liberties?

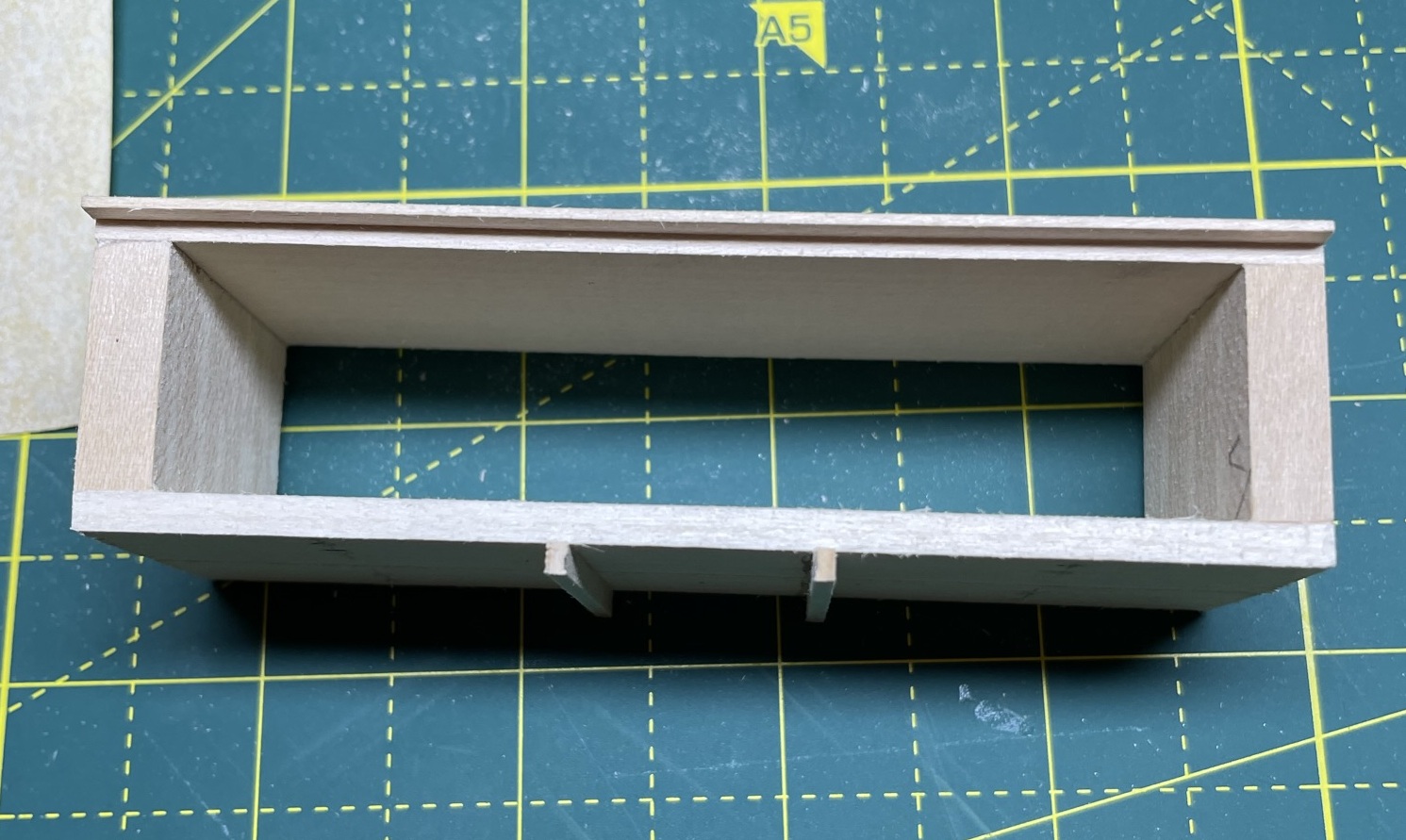

My modeling target is 1890-1900 central Vermont, and these boxcars would have been build sometime between 1867-1880. Inspired by an old post from CNR Glen I thought I would try to apply some serious age to the car. Perhaps built around 1867 and ran hard with little love for the next 30 years? I started by staining all the exterior parts lightly with a mix of isopropyl alcohol and cheap black paint. Next, the basic floor/roof/end frame. With credit due to the excellent and free guide from Labelle: https://www.labellemodels.com/perfect-construction-p-1224.html

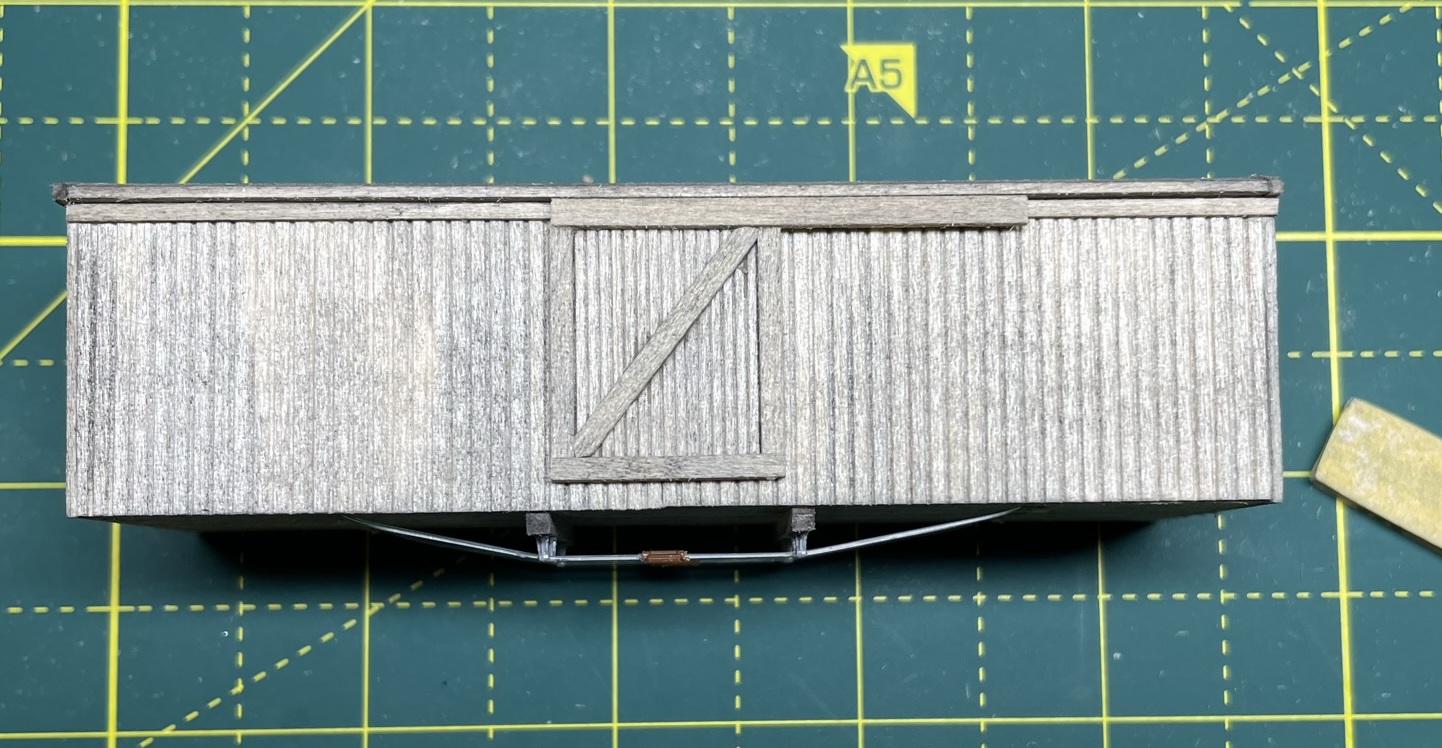

Added some lead sinkers as weight, and finished off the truss rods before sealing up the sides (although I would later have to undo my work to shorten the truss rods a bit, oops):

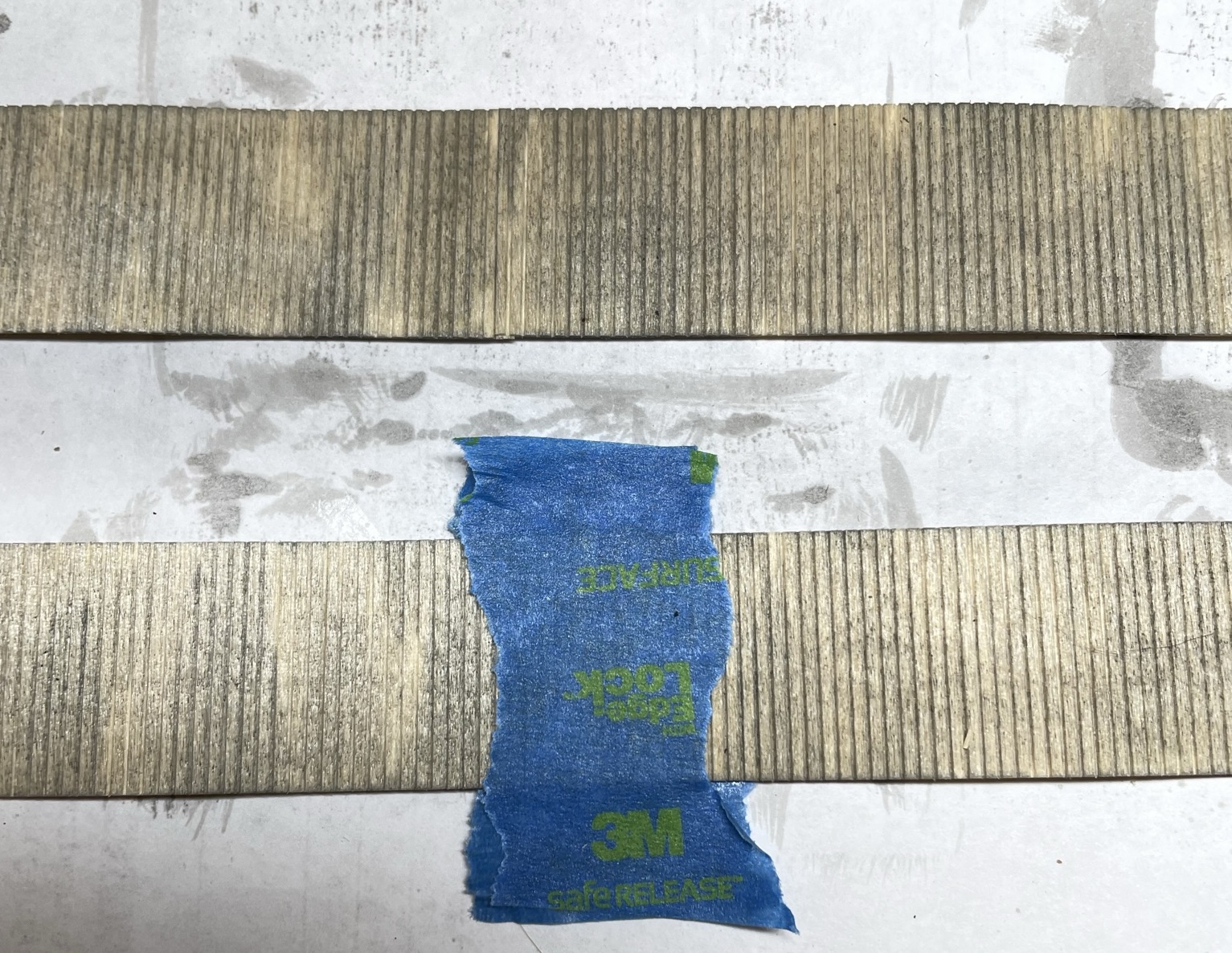

Next up, gluing some bits of scribed siding together. Again, this tip came from a Labelle guide: https://www.labellemodels.com/good-sides-forever-p-1223.html

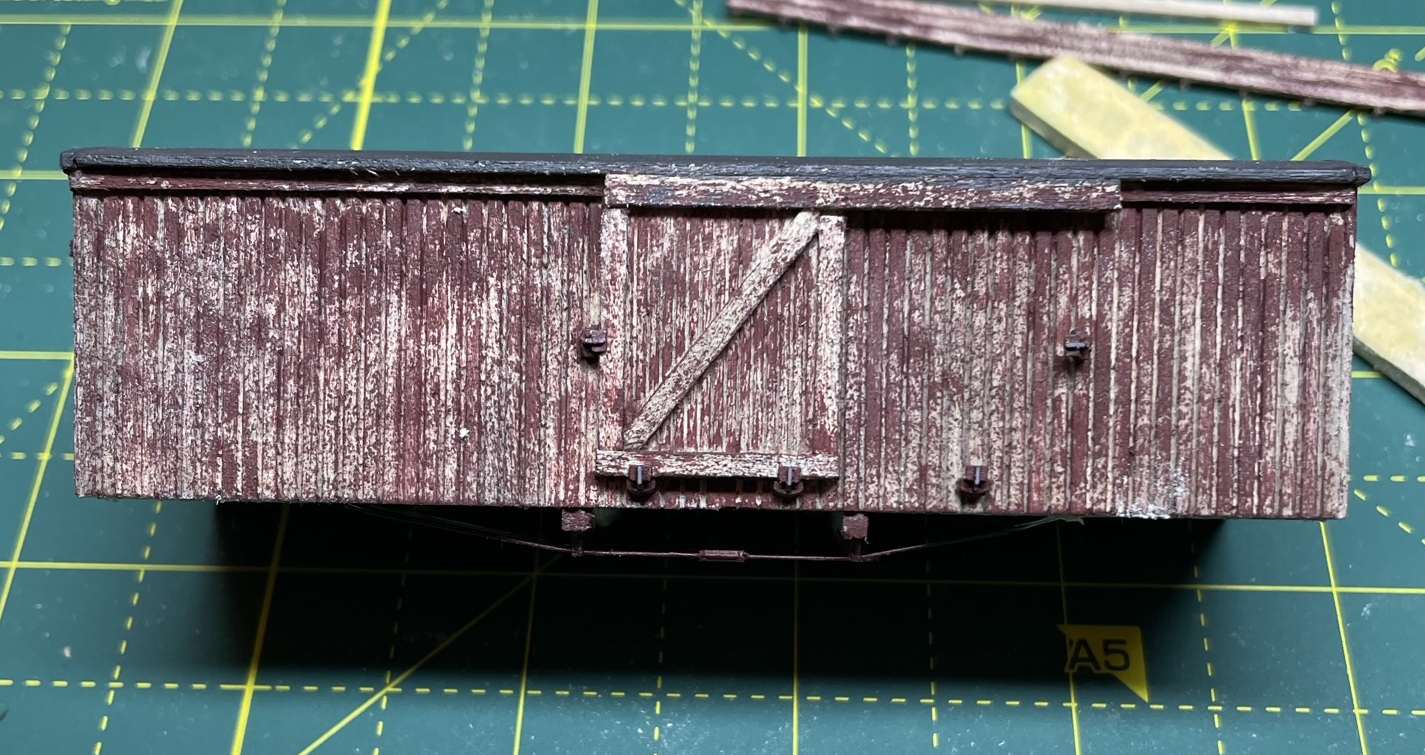

Siding and door added. This siding is 1/16" spacing or roughly 6 scale inches. Most boxcar kits from this era seem to be 0.040 spacing (which is what I used for the door) but I decided to see how it looked. I actually very much like the look of the 1/16 siding, it feels more rustic to me.

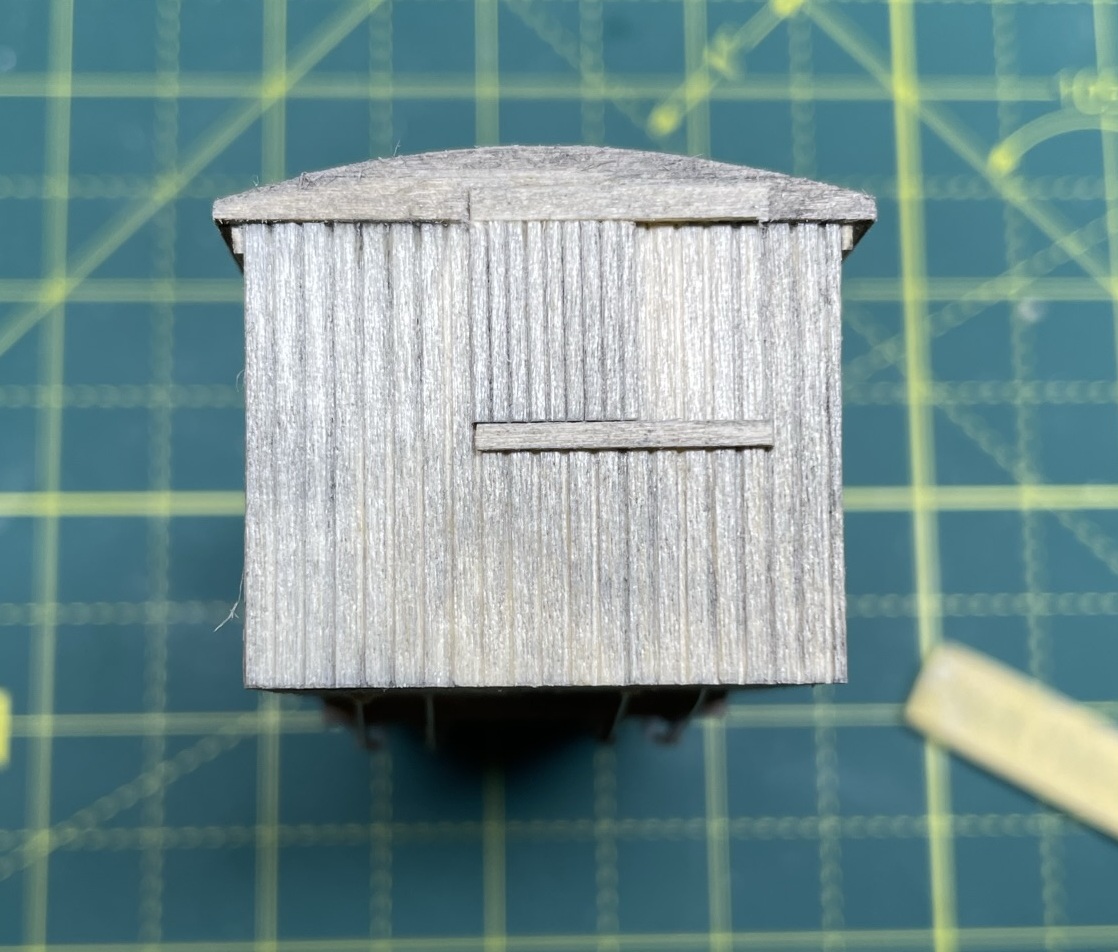

End with window:

Next up, some paint. I was going for a slightly less beat up look than CNR Glen's boxcar, and this turned out to be surprisingly hard. The difference between a dry brush and a not dry brush is a fine line indeed, which I rode with only modest success. A little work with a steel bristle brush after painting knocked back the areas where it got away from me.

The paint on the siding is Microlux Roof Red from Micromark (highly recommend these paints btw, you get a big bottle for the money and the coverage is quite nice. For finer detail work I like to thin slightly with water). The roof is painted with a very old bottle of Polly Scale grimy black.

Added a roof walk and some details, mostly from Tichy Train Group:

I applied light gray weathering chalk on the roof, and added some decals.

I did a crappy job of setting the decals, but I let it be as I figured it would add to the beat up look I was going for. The decals came from 3dptrain: https://3dptrain.com/shop/gbc-b016/

I sprayed with dullcote at this point, which almost seemed to have eaten the decals a bit I've never seen that happen before, maybe something in these decals didn't play nice with the dullcote? In any case, it turned out to look GREAT if you're trying to model a beater car, so no harm no foul here!

I've never seen that happen before, maybe something in these decals didn't play nice with the dullcote? In any case, it turned out to look GREAT if you're trying to model a beater car, so no harm no foul here!

To finish up, I dry brushed some red streaks over the decals, then applied more isopropyl wash to try and darken some of the scribe lines and other places I thought grime might built up. A little rust was added to the grab irons, door fittings, corner straps, and truss rod ends. Trucks are Tichy arch bar with Kadee metal wheels. They don't look quite as nice as the proper Kadee all metal arch bars but they are a LOT cheaper. These were painted black with some rust dry brushed and then more light gray weathering chalk. Overall - really like this technique for making old beat up cars, big thanks to CNR Glen (who, sadly, doesn't seem to have visited here since 2016).

This is the only photo I have of the prototype:

Definitely a few things I'll do differently next time in order to get a bit closer to the proto:

- Use regular non-curved boxcar roof (on order!)

- Coloring looks more like a tin roof, so probably use silver paint instead of grimy black

- Omit roof walk

- Move grab irons from the side to the end

- Change diagonal brace on the door for a horizontal one

- Place a runner under the door instead of brackets

- Move the number to the right of the door

- Maybe shorten to 25 scale feet? Although to my eye, the ~30' I produced looks pretty good

My modeling target is 1890-1900 central Vermont, and these boxcars would have been build sometime between 1867-1880. Inspired by an old post from CNR Glen I thought I would try to apply some serious age to the car. Perhaps built around 1867 and ran hard with little love for the next 30 years? I started by staining all the exterior parts lightly with a mix of isopropyl alcohol and cheap black paint. Next, the basic floor/roof/end frame. With credit due to the excellent and free guide from Labelle: https://www.labellemodels.com/perfect-construction-p-1224.html

Added some lead sinkers as weight, and finished off the truss rods before sealing up the sides (although I would later have to undo my work to shorten the truss rods a bit, oops):

Next up, gluing some bits of scribed siding together. Again, this tip came from a Labelle guide: https://www.labellemodels.com/good-sides-forever-p-1223.html

Siding and door added. This siding is 1/16" spacing or roughly 6 scale inches. Most boxcar kits from this era seem to be 0.040 spacing (which is what I used for the door) but I decided to see how it looked. I actually very much like the look of the 1/16 siding, it feels more rustic to me.

End with window:

Next up, some paint. I was going for a slightly less beat up look than CNR Glen's boxcar, and this turned out to be surprisingly hard. The difference between a dry brush and a not dry brush is a fine line indeed, which I rode with only modest success. A little work with a steel bristle brush after painting knocked back the areas where it got away from me.

The paint on the siding is Microlux Roof Red from Micromark (highly recommend these paints btw, you get a big bottle for the money and the coverage is quite nice. For finer detail work I like to thin slightly with water). The roof is painted with a very old bottle of Polly Scale grimy black.

Added a roof walk and some details, mostly from Tichy Train Group:

I applied light gray weathering chalk on the roof, and added some decals.

I did a crappy job of setting the decals, but I let it be as I figured it would add to the beat up look I was going for. The decals came from 3dptrain: https://3dptrain.com/shop/gbc-b016/

I sprayed with dullcote at this point, which almost seemed to have eaten the decals a bit

To finish up, I dry brushed some red streaks over the decals, then applied more isopropyl wash to try and darken some of the scribe lines and other places I thought grime might built up. A little rust was added to the grab irons, door fittings, corner straps, and truss rod ends. Trucks are Tichy arch bar with Kadee metal wheels. They don't look quite as nice as the proper Kadee all metal arch bars but they are a LOT cheaper. These were painted black with some rust dry brushed and then more light gray weathering chalk. Overall - really like this technique for making old beat up cars, big thanks to CNR Glen (who, sadly, doesn't seem to have visited here since 2016).

This is the only photo I have of the prototype:

Definitely a few things I'll do differently next time in order to get a bit closer to the proto:

- Use regular non-curved boxcar roof (on order!)

- Coloring looks more like a tin roof, so probably use silver paint instead of grimy black

- Omit roof walk

- Move grab irons from the side to the end

- Change diagonal brace on the door for a horizontal one

- Place a runner under the door instead of brackets

- Move the number to the right of the door

- Maybe shorten to 25 scale feet? Although to my eye, the ~30' I produced looks pretty good