I've been doing a bit of research on alternative motor-axle drive systems to utilize on a 'disguised pusher' to help power up our steam engines that have been trying mightily to do it all on individual selfs.

A few days ago I ran across a few references, including this very convincing video,..

Look at the pulling capabilities,...WOW

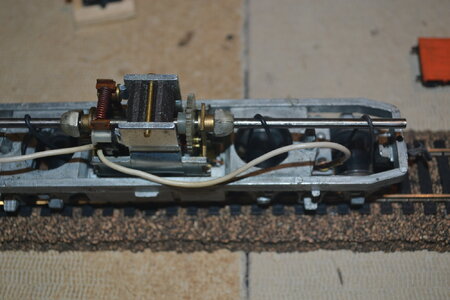

Look at the potential simplicity of these drives.

Look at the potential space to add weight for traction improvement.

I thought this subject deserved a new subject discussion.

A few days ago I ran across a few references, including this very convincing video,..

Look at the pulling capabilities,...WOW

Look at the potential simplicity of these drives.

Look at the potential space to add weight for traction improvement.

I thought this subject deserved a new subject discussion.