ModelRailroadForums.com is a free

Model Railroad Discussion Forum and

photo gallery. We cover all scales and sizes of model railroads. Online since 2002, it's one of the oldest and largest model railroad forums on the web. Whether you're a master model railroader or just getting started, you'll find something of interest here.

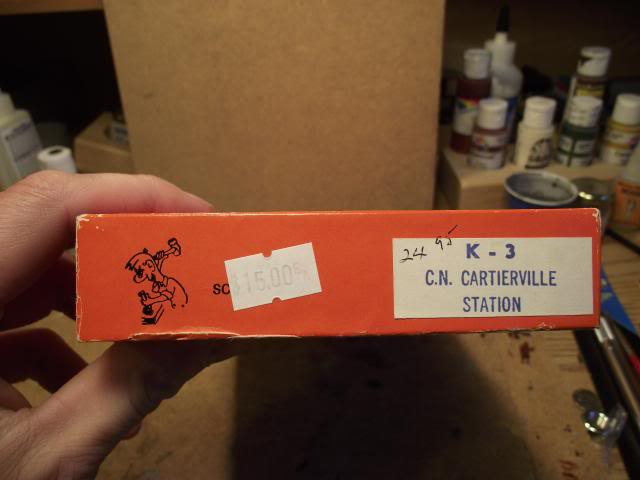

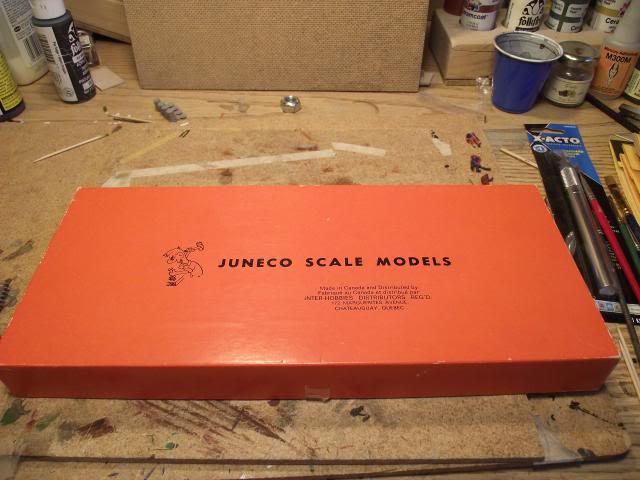

I recently bought this kit at a swap meet so I could upgrade my smaller town's station. I originally had Woodland Scenics flag Depot for the station but this kit will be more to my liking and at 15$ the price was right.

It's definitely an old-school type kit, no laser cutting here. Most of the walls are die-cut and from what I can tell doors and windows have to be cut out by the builder.

The doors and windows are metal castings. The kit also includes a bag of extra cast metal details (figures, baggage ect).

Great buy on that kit, Glen. It usually sells for $50-$70 on Ebay. Just make sure to use a good sharp blade and minimal pressure when cutting out the doors and windows. The old wood gets very brittle. I have a dozens of these kits to build so will be watching your thread. Ron

I also have the Juneco 250 ton CN ice house to be built later.

I did a bit of work surveying the land that the station will go.

I recently added a 9 X 25" section onto my layout where the station will go. Onto this same area I placed my Octagon Water tower, and a Woodland Scenics Ticket office that I made into a CNR Agent's office.

The Floor plan come in three parts, the main station and the platform wings. The platform can be much longer that what I decided on but I don't have that kind of real estate.

Back on the workbench. I taped the floor plan to a 1" piece of high density foam with a sheet of wax paper over it.

The floor joists are all cut to size if you are building the full 28" platform. Since my platform is considerably smaller I did have to cut some timbers to size. I first laid out everything that I would need. Then I stained them all in an A&I wash twice. The first dip in the wash made them come out a bit light so a second one was needed.

After the wash was dry I framed in the station floor. The instruction recommend that you build the platform and station separately for easy of handling. I pinned the frame together while the glue set up.

The Platform frame is pinned and glued the same way, there is just more of it!

While waiting for the glue to dry I cut the station floor out. the interior walls are marked on the floor but aren't included in the kit. I haven't decided if I'm going to go that far. I don't plan to have a removable roof and the windows aren't that big to see inside.

I glued the floor to the floor braces, and the platform decking to it's braces.

The platform decking is made of scribed sheets , cut to width but not to length. There are 4 parts to the size of my decking. I glued them of, flush with the station side and overhanging the trackside. After the glue was dry I added nail holes with a pin to each side of the planking.

I then stained the deck with Flo-stain walnut.

The stain makes the nail holes pop out quite nicely.

I started work on the walls

The walls are multiple parts, layered from top to bottom. The window and doors are partly milled out. You cut between the two milled cuts to for the space for the wind or door casting

I found the none of the window of door castings fit in the spaces, so I had to cut some more out, both on top and on the sides.

Fitting the windows was easy, with the exception of two, they all are flush with the bottom of the wall. I used the full sized drawings of the walls to figure out how to trim the doorways to fit.

A couple hours and all the windows and doors are fitted.

After this I primered all the windows and doors in flat white. Next I'll start adding the rest of the wall pieces.

Thanks, I`m enjoying the build.

Finished the walls today. As I mentioned before they are multiple parts with the large clapboard on the top and a number of stripwood parts added to the bottom

The vertical board piece is cut to height and you cut everything to width. I assembled the walls on a flat metal surface so everything would be true.

The finished wall looks pretty good, almost a shame I have to paint it!

I checked the door and window openings to make sure I had them right. The two smaller stripwood pieces have to be trimmed flat with the rest of the wall so the doors will lie flush with the wall. As I mentioned before I primered the windows and doors in flat white.

it took a couple hours to finish up all the walls but here they are. I'm going to paint the station with Apple barrel country grey to match the Kannamodel lineside structures that I finished a few weeks ago. The exception will be the corner trim, windows and doors which will be antique white.

Thanks I painted the walls and added the corner pieces yesterday:

I used Barn red by Ceramcoat, over a grey primer. The windows, doors and corner parts were sprayed with flat white.

The windows aren't glued in yet. I'm using a liquid window maker (Chrystal Clear) and two of the windows didn't turn out right so I'm re-installing them.

Quite a bit of progress to report. I installed all the windows and doors, then put the walls up

The track side has a large baggage door and two smaller passenger doors, plus the extra windows for the office.

The rear side has a double passenger door for both the passenger and baggage sections. I have a small flaw in the wall section for the passenger doors where it has a gap between the wall the floor. I plan to use the extra decking material to make a wood sidewalk here to mask the flaw later.

Here's the track side with the decking temporarily installed. As for an interior I've decided against it. I do have parts for the office but since the station will be placed with the office facing away from viewers it's not really worth it. I'll add a hole in the floor for placing lighting though.

here comes the hard part though, the roof!

I had already added the eve brackets when I finished putting the walls up, now comes the roof structure

I started with the rafter frame pinned and glued together on it's template. When that was dry I glued it to the eve brackets.

After that was dry I added 52 rafter tails. To this the roof fascia will be attached. I'm crossing my fingers that it will turn out right.

I consider the Juneco structures to be equal to the Campbell structures in quality. I don't think that you'll have a problem with them at all.

Everything looks real good so far.

I managed to get the roof on. That's a load off my mind. The roof is the first thing people see and its important to get it to look right. All the roof parts are printed on card. Just in case I photocopied them all before I started cutting them out. I also painted the undersides in a dark brown so the white wouldn't show under the eves. The roof went on in a few steps

First came the 'truss' parts.

Then the main roof. The slope of the roof in different between the main roof and the overhangs.

Then the ends

The two gabled sides are built of two parts I glued and clamped the upper part first

Then the lower.

The finished roof, before shingles. I do have some gaps in the roof panels, most noticeably between the main and end parts. I'm not too concerned because they will be covered in shingles. I'll probably just glue some paper over the gaps before I shingle.

That's several things I didn't know. I wondered where the company name came from and I wasn't aware it was even in operation any more.

I started to shingle the roof. First you have to make the shingles. I guess it kind of dates the kit if the shingles have to be semi-made by the builder. First there are about 30 sheets of paper with small vertical cuts in them.

You have to cut the vertical lines in half, right down the middle, and make two other cuts 3/16" on each side of your first cut. This makes 8 shingle strips per sheet. After that I had a pile of shingle strips:

Before I added the shingles I used white glue to fill in the gaps in the roof pieces, then I painted seams an oxide brown so when I eventually do light the building there won't be any light leaks.

Then I started adding the shingle strips, starting from the bottom and working my way up. I glued the strips on using Elmer's white glue.

I'm about halfway through the shingling now, hoping that I have enough for the job! I might have mis-cut a few of the shingle strips and made them un-usable.

Looking good, Glen. Don't worry about running out of shingles. If you don't have enough, let me know and I'll send you some. I have the engine house kit and won't be using the shingles from it, so I have a pile of them. Ron.

Thanks Ron, that's good to know. I was originally going to use Campbell's profile shingles on the station but then I realized that I wouldn't have enough to cover. I think the Juneco shingles will look okay when I get them painted and weathered a bit.

You are right. The Juneco shingles look just as good as the Campbell shingles do, just a slightly different style. I find the Juneco style shingles easier to work with though. They are nice and flat unlike the Campbell's which are rolled.

Glen,

The station is looking very good! I only have 13 Campbell building to build, and this Juneco structure has inspired me to start on them. The construction looks very similar to the Campbell's, and should go well. First though I have to find a place to store them until they are finished. I have 2 other Campbell structures that I built more than 25 years ago. They have inhabited the top of my layout for almost 10 years, but have gotten damaged, and I need to repair those as well.

To Glen from Glen,

That is one fantastic build, more than I ever tried. I was surprised when I saw the shingles as I copied an idea from somewhere to make my own.

http://armchairmodelbuilders101.com

http://armchairmodelbuilders101.com

Glen Wasson aka

Armchair

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website

(Learn More Here)