CambriaArea51

Well-Known Member

Started this out about 5 years ago. Athearn I believe did a brief run of these cars with the middle section widen so the trailer would go through curves and switches without affecting the trailer tires causing it to fall off. Problem is even though you have a widen section on the trailer it moves and won't be straight on the trailer afterwards.

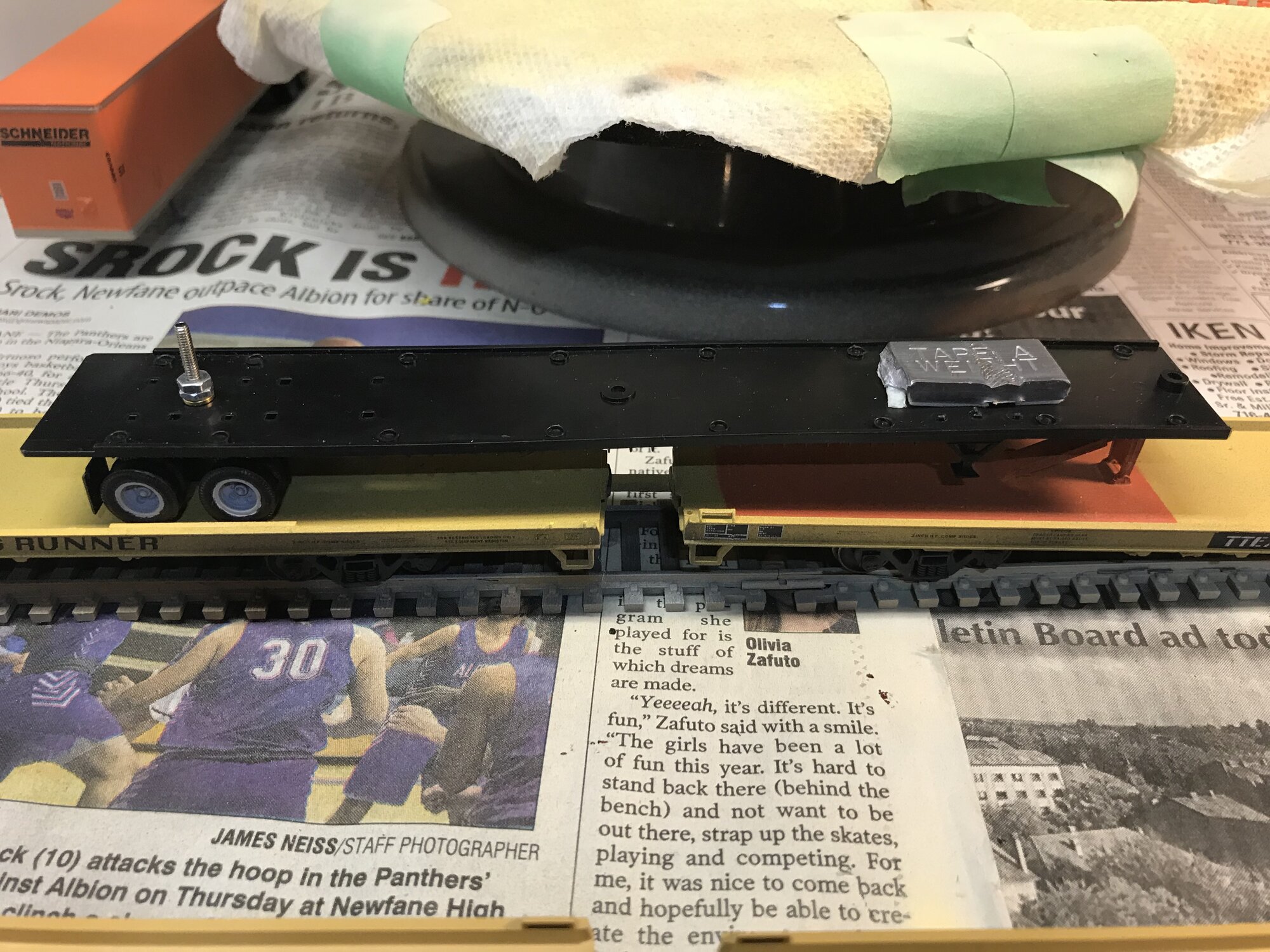

So to do this I used Walthers channel side 85' flatcar and Bowser 53' trailer. I figured if the running gear could swivel when going through curves and switches it can stay on the flatcar and always stay straight once through the curve.

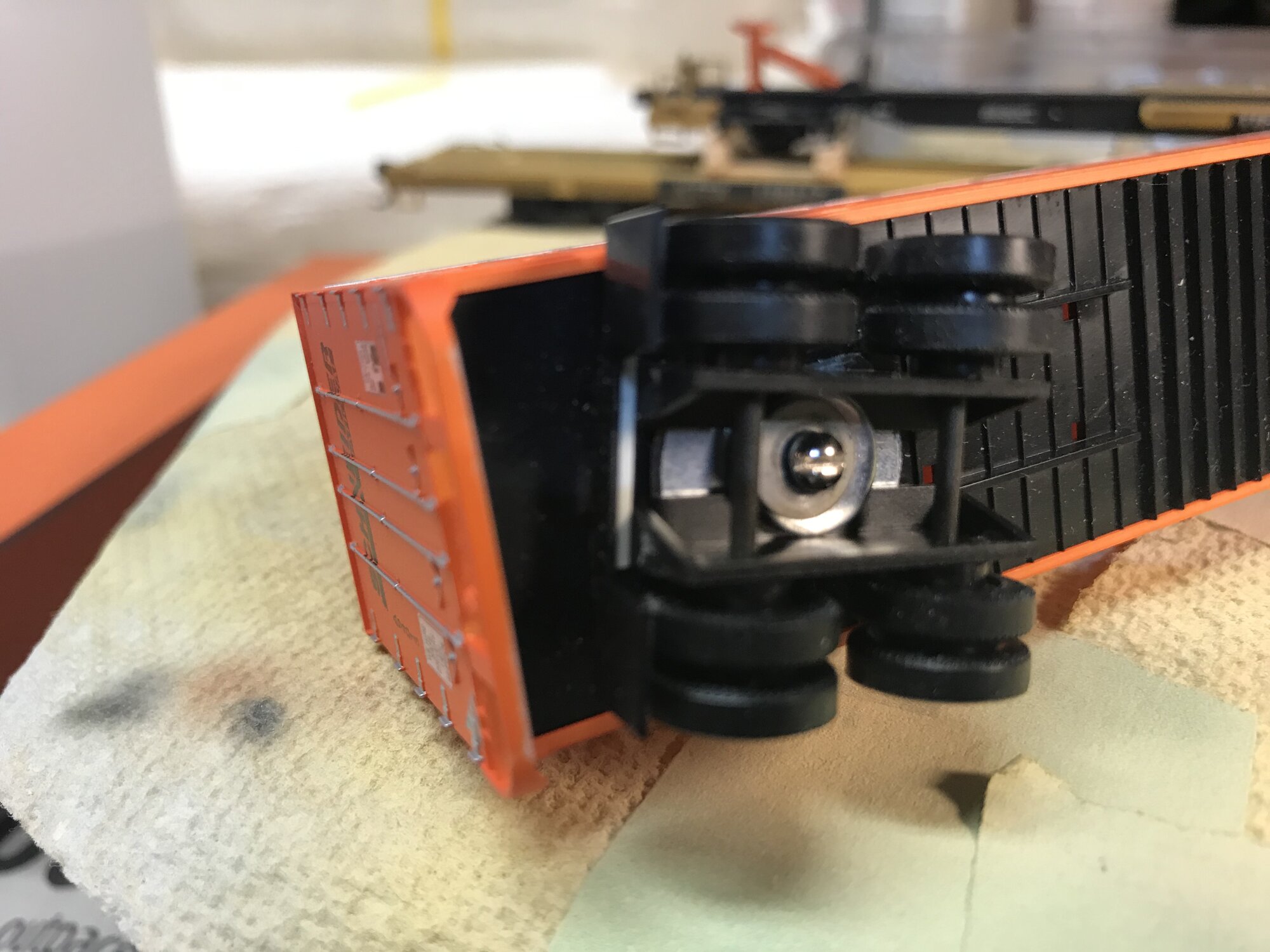

The Bowser trailer is perfect for this because the trailer running gear is assembled using 2 wedge pieces.

The distance between the axles on the trailer was what was needed to put a screw and washer in between.

I cut the sides of a washer to fit in between the rails so the running gear could sit on that and be able to swivel.

With things put together a weight is added to put pressure on the 5th wheel hitch.

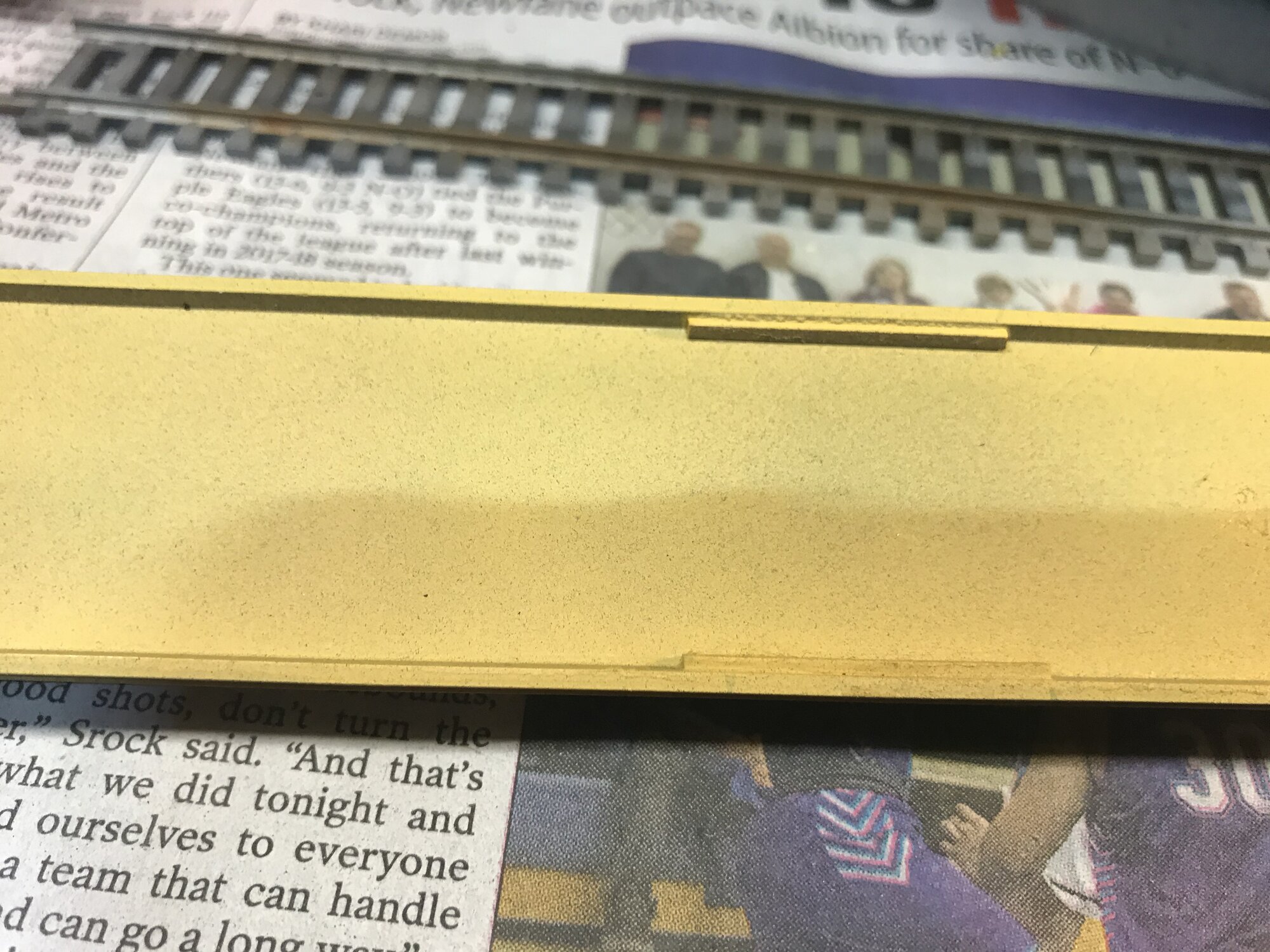

A couple of pieces of strip styrene is added to the sides of the channel to take up any slack from the wheels to the channel side of the flatcar.

When completed it's able to go around curves with a suttle notice to the flex of the running gear.

So to do this I used Walthers channel side 85' flatcar and Bowser 53' trailer. I figured if the running gear could swivel when going through curves and switches it can stay on the flatcar and always stay straight once through the curve.

The Bowser trailer is perfect for this because the trailer running gear is assembled using 2 wedge pieces.

The distance between the axles on the trailer was what was needed to put a screw and washer in between.

I cut the sides of a washer to fit in between the rails so the running gear could sit on that and be able to swivel.

With things put together a weight is added to put pressure on the 5th wheel hitch.

A couple of pieces of strip styrene is added to the sides of the channel to take up any slack from the wheels to the channel side of the flatcar.

When completed it's able to go around curves with a suttle notice to the flex of the running gear.