dgrafix

Well-Known Member

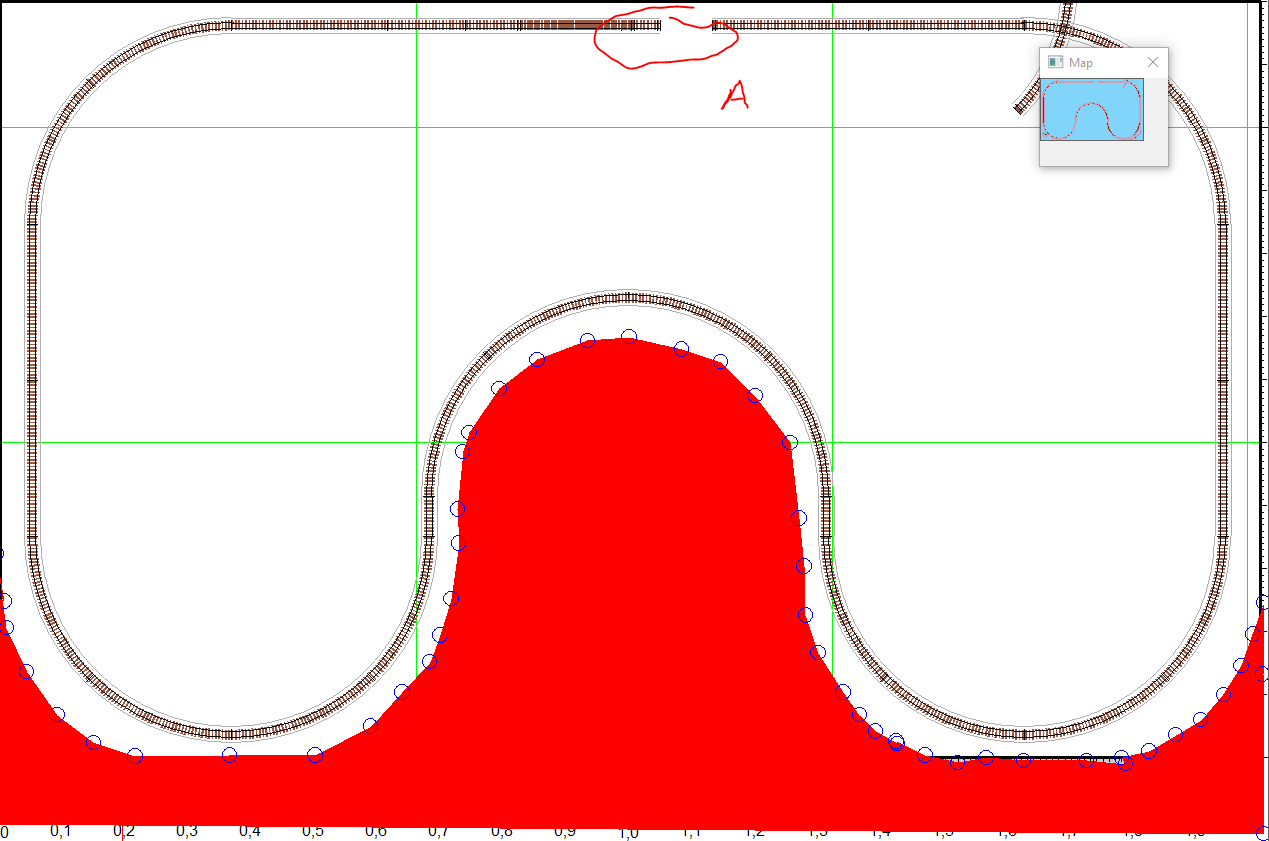

Hi, bit of a noob here. I am trying to do a C shaped layout using Kato Unitrack with a standing area (red). Space is limited so will have to fold down on a board (says her!).

Anyway got this little problem that when using the 315 radius track, the CAD is telling me that the peices are out of whack and i just cannot find any way to insert a peice to make it knit. I can get to just a few MM but have tried all sorts of combos.

You can see my problem. I have tried a few other radius on the inner curve too but there must be a way:

Anyway got this little problem that when using the 315 radius track, the CAD is telling me that the peices are out of whack and i just cannot find any way to insert a peice to make it knit. I can get to just a few MM but have tried all sorts of combos.

You can see my problem. I have tried a few other radius on the inner curve too but there must be a way: