ModelRailroadForums.com is a free

Model Railroad Discussion Forum and

photo gallery. We cover all scales and sizes of model railroads. Online since 2002, it's one of the oldest and largest model railroad forums on the web. Whether you're a master model railroader or just getting started, you'll find something of interest here.

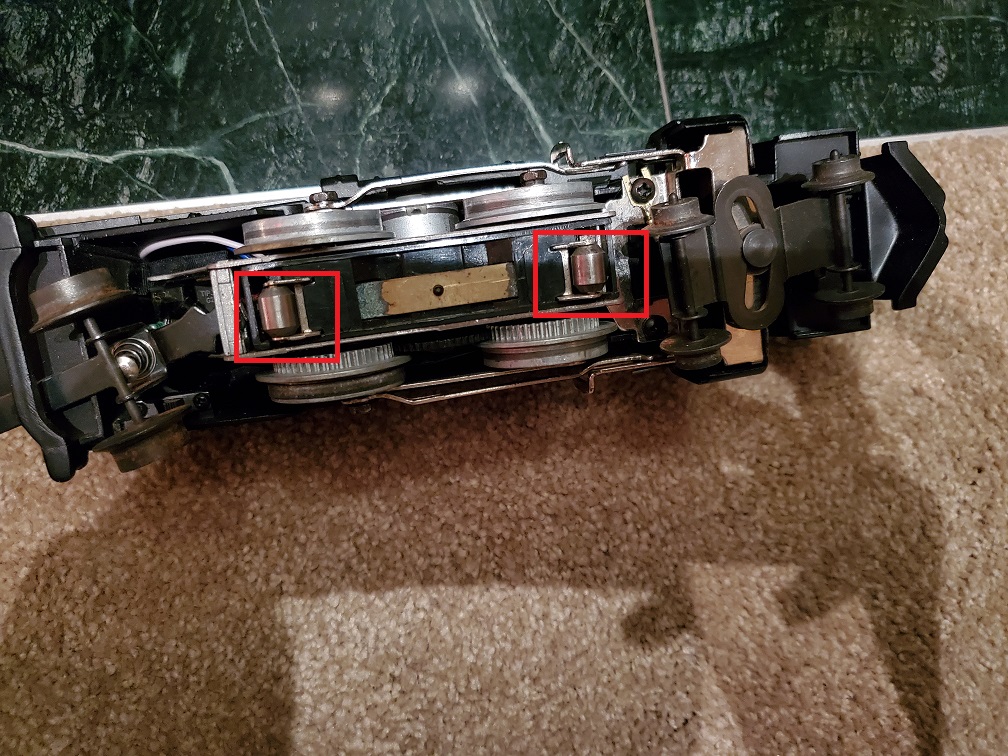

I have been working on one of my steam locos here. I got the brass spring contact strip cleaned off where it contacts the brush frames, as well as the brush frames themselves. I also got the outside of the rollers cleaned.

However, the inside hole of the rollers to the pins is where I don't have much conductivity. I put the brush frames in a vice and rolled the rollers with a board back and forth several times to try and get the metal to clean itself off inside the hole, but no luck.

Any ideas on rectifying the scenario short of replacing the brushes? The axle is a pin. I am tempted to try tapping the pin out, but that would take quite a bit of finesse and care.

I used alligator test leads off the transformer contacts to check points of conductivity. I grounded one inside the loco then used the other one touching different points of the circuit. The frames of the brushes have good conductivity, but the rollers do not. With the frames having conductivity that means the brush frame to spring strip connection is good.

Thoughts?

Have you tried putting some alcohol inside it and then rolling it on the board?

My thoughts were along the same line as Lukes, except I was thinking holding the engine in the up right position, and giving the area of concern a few short shots of brake clean. I'm guessing that is O scale? So don't know if that is possible or not with it's internal workings. Just throwing that out there........

With what ever cleaner you use, would a micro-brush help you to get in there and do some cleaning?

O scale, yes, which is why I posted in the O scale portion of the forum here.

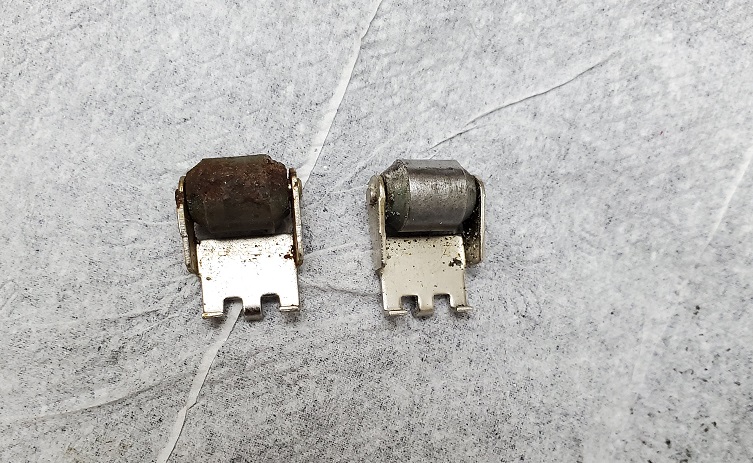

The brushes pop in and out real easy - that is the 2 assemblies in the first picture (one before cleaning, one after - they are both "clean" as pictured installed in the loco in the 2nd picture).

As to the alcohol or brake clean - I would be more comfortable with alcohol. I use denatured alcohol as flux cleaner/solvent for circuit boards so that would be pretty easy to try. Though, I have my doubts about it.

When I rolled the rollers with the board the brushes were out of the loco and clamped in my vice on my work bench. One of them I rolled so much the assembly got warm. The rear brush has a flat spot in it that makes it not "roll" very easy, so I wasn't able to get that one moving as much as the front one.

Since the rollers look to be rather easy to remove and one has a flat spot in it anyway, I would just replace them both and be done with it.

The roller with the flat spot obviously needs to be replaced. As a last resort I would dunk it in a weak acid.

I tried the denatured alcohol. That helped things along. The continuity isn't 100% but I got it to work some. I stacked several cars behind it to give it a good load to where I could crank the transformer up without sailing the loco off the track. I ran that a few circuits. That helped the continuity a bunch running things "in". I took all the cars off except the coal tender and am letting it run circuits to see if it will run in a bit more. The wheels have some corrosion on them so I am hoping letting things run for a bit will get down to bare metal again. Thanks for the tips!

Gomez Addams

Staff member

You can remove the roller assemblies and place them, one at a time, in a small vice. Using a wire brush attachment on your Dremel tool, you can run the wire brush on the big roller part, which should also turn the roller. That will help clean the roller with the brush, and the movement on the pin will clean off the corrosion inside the roller.

I used alligator test leads off the transformer contacts to check points of conductivity. I grounded one inside the loco then used the other one touching different points of the circuit. The frames of the brushes have good conductivity, but the rollers do not. With the frames having conductivity that means the brush frame to spring strip connection is good.

Thoughts?

Also try electrically conductive lubrication for the pin of the roller. There are several brands. The one I am holding in my hand is called "Conducta Lube & Cleaner"

www.aerocarlubricants.com I beleive Bachmann makes one, as does Atlas, and I am certain several others.

Hit them with CLR or some other kind of corrosion remover. Then rinse them in alcohol very well, then use the lube Iron Horseman recommended.

If they still have too much resistance, you'll need to replace them. Try ttender.com, drtinkertrains.com, or legacystation.com for the parts. Unfortunately, I just heard the owner of justtrains passed away and orders are not forthcoming at this time. Once you have the part #s, you can also try ebay.

As for the rollers coming off the holders coming off easily, not if they're like most rollers (I've never owned a Scout so don't have a reference). On their other locos, there is a pin that runs all the way through the roller so replacing just the roller is a pain.

And I'd take some scotchbite to the wheels to get rid of the rust. Hoping the track will rub it off will spread the rust particles to the track, leading to quicker oxidation of the track. NEVER use steel wool to clean wheels on an assembled locomotive. 3M does make a "synthetic steel wool" that is basically different abrasive ratings of a product similar to scothchbrite that Lowes and Home Depot carry. No metal in it.

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website

(Learn More Here)