You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Soldering rails

- Thread starter mwc1416

- Start date

ModelRailroadForums.com is a free Model Railroad Discussion Forum and photo gallery. We cover all scales and sizes of model railroads. Online since 2002, it's one of the oldest and largest model railroad forums on the web. Whether you're a master model railroader or just getting started, you'll find something of interest here.

Also, if you don't leave expansion gaps when the rail and benchwork change the weakest spots will fail under pressure. Generally the weakest spots are turnouts where we have enough challenges.

Personally, I prefer to solder a lot of my rail joints for better electrical continuity, including turnouts !!! But I still may leave a few unsoldered joints here and there for expansion purposes or future layout disassembly purposes. My best advice is to leave a small rail gap (business card thickness or similar) at ALL joints, soldered or not. That way, if rail buckling ever occurs in a section of soldered tracks, simply heating up one or two soldered joints with the soldering iron to release the compression will cure the buckling in that area. I found that out the hard way on the last N-scale layout that I built after butting all rail sections tight together before soldering

!!! But I still may leave a few unsoldered joints here and there for expansion purposes or future layout disassembly purposes. My best advice is to leave a small rail gap (business card thickness or similar) at ALL joints, soldered or not. That way, if rail buckling ever occurs in a section of soldered tracks, simply heating up one or two soldered joints with the soldering iron to release the compression will cure the buckling in that area. I found that out the hard way on the last N-scale layout that I built after butting all rail sections tight together before soldering  !

!

Also, if one can do a good job of soldering the rail joints and track feeders, then they should have no problems using only one set of feeders per each group of soldered track sections. I do all of my soldering like this when building layouts, and never have electrical issues afterwards.

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website (Learn More Here)

logandsawman

Northern Pacific history enthusiast

I do not solder any joints and like to leave a 1/32 space where rails meet. I am using flex track so my sections are longer than using sectional track, not sure if that makes a difference. Especially when you have rolling terrain and lots of curves. Over time it is surprising how many of those spaces disappear, probably every other one. Some of my gaps I make a bit bigger. I like the clickity sound as I am modelling pre war and those tracks were not the long 1 mile sections they use today.

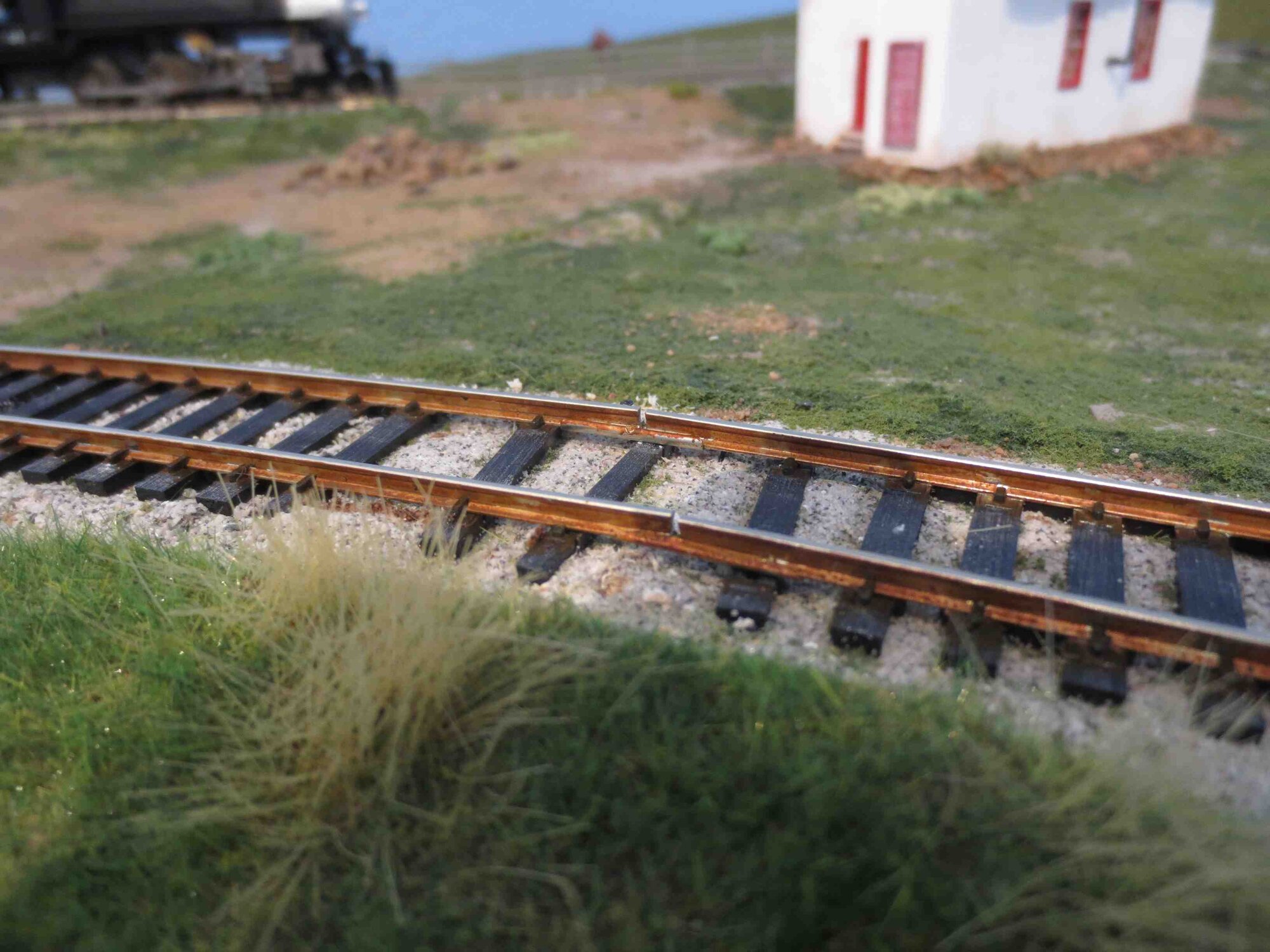

Here are some of my gaps. This is a 22 radius curve with flex track. You will notice stuff does not line up perfect but I do not have any derails here. I prefer to offset the joints a little more but since this works, I am going with it.

I notice many modellers like to solder their rails, I am thinking they have much a more stable base or less changes in temp/humidity than I experience.

I am not aware if there is a standard for soldering.

Dave LASM

Here are some of my gaps. This is a 22 radius curve with flex track. You will notice stuff does not line up perfect but I do not have any derails here. I prefer to offset the joints a little more but since this works, I am going with it.

I notice many modellers like to solder their rails, I am thinking they have much a more stable base or less changes in temp/humidity than I experience.

I am not aware if there is a standard for soldering.

Dave LASM

Last edited:

jhn_plsn

New Member

I have built a few N scale layout and through my experiences I prefer to solder in curves but leave straight connectors a bit of space to float. That said my projects are always in the garage so temperature and humidity swings create new challenges every summer. I use Atlas code 55 flex and it seems to expand and contract quite a bit. Every year there seems to be a new adjustment to make by adding another gap.When sodering rails, is it recommended to soder every joint? or do I need to leave some joints with joiners to allow for expansion. Thanks

Also, if you don't leave expansion gaps when the rail and benchwork change the weakest spots will fail under pressure. Generally the weakest spots are turnouts where we have enough challenges.

santafewillie

Same Ol' Buzzard

There is no general recommendation on soldering rails other than to do it as carefully as you can. Like Dave, I do not solder and I leave gaps the thickness of a business card every 6'-8' for benchwork swelling and rail expansion. Although honestly, rail expansion is not as great an issue as some would have you think. Wood expansion and contraction is a greater problem. I have over 1300' of primarily flextrack, all code 100, with 115 Atlas switches and I haven't had any problems in over ten years of existence. I do have power feeders attached every 6' or so, closer together if I am using sectional track. This is my experience only, others believe that soldering every piece of track is necessary.When sodering rails, is it recommended to soder every joint? or do I need to leave some joints with joiners to allow for expansion. Thanks

Mixed Freight

Well-Known Member

Agreed on the expansion/contraction issue, santafewillie! Rail expansion on the prototype railroads is caused by the sun beating down on the steel rails all day long, causing them to heat up, expand, and finally buckle. "Rail expansion" on model railroads is generally caused by another gremlin - shifts in the humidity levels. The wooden benchwork shrinks down during the dry season, but the rail doesn't, and thereby the rail can buckle. A lot of modelers then mistakenly think that their rails have expanded, when in reality it is the benchwork that has contracted.There is no general recommendation on soldering rails other than to do it as carefully as you can. Like Dave, I do not solder and I leave gaps the thickness of a business card every 6'-8' for benchwork swelling and rail expansion. Although honestly, rail expansion is not as great an issue as some would have you think. Wood expansion and contraction is a greater problem. I have over 1300' of primarily flextrack, all code 100, with 115 Atlas switches and I haven't had any problems in over ten years of existence. I do have power feeders attached every 6' or so, closer together if I am using sectional track. This is my experience only, others believe that soldering every piece of track is necessary.

Personally, I prefer to solder a lot of my rail joints for better electrical continuity, including turnouts

Also, if one can do a good job of soldering the rail joints and track feeders, then they should have no problems using only one set of feeders per each group of soldered track sections. I do all of my soldering like this when building layouts, and never have electrical issues afterwards.

Selector

Well-Known Member

I solder most of my joints, regardless of where they are, and that includes on curves or on tangents. I leave some joints open so that changes to the underlying structure of the layout, usually milled lumber of a kind, will not cause buckling when humidity levels change. I don't get extremes of temperature or humidity in my train room because I dehumidify 24/7, and the room is insulated and poly'd.

In case it is of interest to the OP and others, Code 100 N/S rail that is of a continuous (not cut) length of 100' will expand or contract about 1/4" with a change up or down respectively of 30 deg F. That's very small. If your rails buckle one day, it's due to humidity problems, almost certainly drying wood that has shrunk and brought the rail joints too close together.

In case it is of interest to the OP and others, Code 100 N/S rail that is of a continuous (not cut) length of 100' will expand or contract about 1/4" with a change up or down respectively of 30 deg F. That's very small. If your rails buckle one day, it's due to humidity problems, almost certainly drying wood that has shrunk and brought the rail joints too close together.

Iron Horseman

Well-Known Member

Personally, I solder only flex track on curves. I stagger the joints and solder. I do this to help eliminate kinks. But, I also have a rule about rail joiners. Rail joiners go on only once. Put it on, leave it on. If the track has to come apart for some reason it gets a new rail joiner.When sodering rails, is it recommended to soder every joint? or do I need to leave some joints with joiners to allow for expansion. Thanks

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website (Learn More Here)