Numbers

Member

...since my first, and only post. A lot has changed.

I couldn't get DCC to work consistently on the 2x4, I then had. Perhaps there were too many switches and grades. One problem with it, that I only discovered recently, was that a Kato terminal connector was wired backwards. Stuff happens.

Anyway, I abandoned that layout and stripped it down to the 2x4 base. I found a way to squeeze a door size layout in my garage. I cantilevered some shelving so I could work under it. The 28x80 door is attached to the base via a 4' piano hinge, at the back. This will let me hide all wiring between the base and the door, with the added benefit that I won't have to crawl underneath anything to do wiring. At my age, that has become an issue.

I added casters to the existing legs, so the whole thing pulls out easily, once I roll the car out of the garage. Putting it back in place is a snap. To further brace the legs, I built a shelf under the base, supported and braced by the four legs. This provides additional storage under the layout. The whole thing is quite stable and strong.

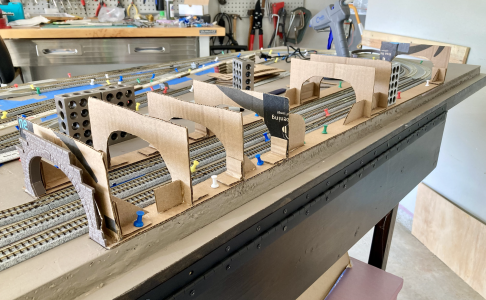

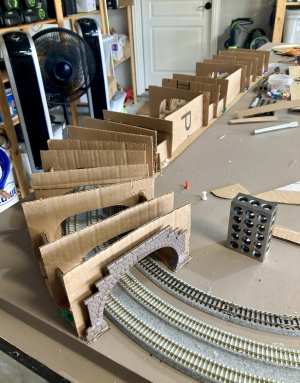

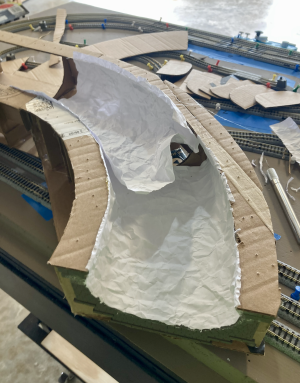

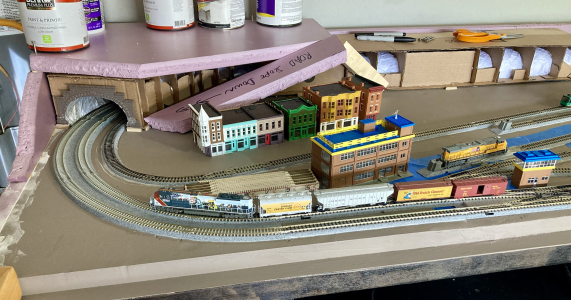

I've decided to have all track at one grade. To avoid that flat look, about 25% of the track will be under a mountain, with an adjoining plateau for a residential area. A commercial district will be at the foot of the mountain.

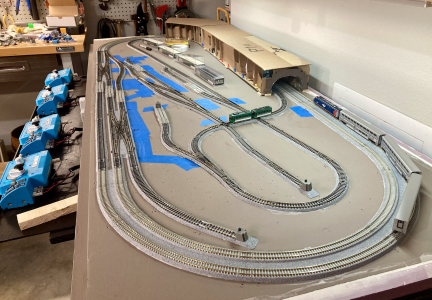

Wanted a double track mainline to run Amtrak on one, with freight on the other. Then a simple switching area. To facilitate the participation of my 4-year old grandson, I added a trolley line in a figure 8. Its justification is bringing town folk to the mainline passenger station. The only industry is the cement plant. I don't think that I can squeeze in another industry.

So, I temporarily wired everything to see how the DCC would work out. It's still just as flaky as ever. I do think that I fried one decoder. I've decided to abandon it and go back to reliable (for me, anyway) DC. Did learn that the fun part of DCC was the sounds of the engine. The one working engine works well under DC, with sounds and light all functioning. I'm going to replace the decoder in the other one, sometime in the future.

I thought of going to the old block system until I figured out that Kato's power routing switches are a great way to control movement. Of course, this layout will need multiple DC controllers: one for each mainline, one for the inner switching area, and one more for the trolley line.

Once all the wiring is complete and tested, it'll be tunnel and town time. Hopefully it won't take another year.

I couldn't get DCC to work consistently on the 2x4, I then had. Perhaps there were too many switches and grades. One problem with it, that I only discovered recently, was that a Kato terminal connector was wired backwards. Stuff happens.

Anyway, I abandoned that layout and stripped it down to the 2x4 base. I found a way to squeeze a door size layout in my garage. I cantilevered some shelving so I could work under it. The 28x80 door is attached to the base via a 4' piano hinge, at the back. This will let me hide all wiring between the base and the door, with the added benefit that I won't have to crawl underneath anything to do wiring. At my age, that has become an issue.

I added casters to the existing legs, so the whole thing pulls out easily, once I roll the car out of the garage. Putting it back in place is a snap. To further brace the legs, I built a shelf under the base, supported and braced by the four legs. This provides additional storage under the layout. The whole thing is quite stable and strong.

I've decided to have all track at one grade. To avoid that flat look, about 25% of the track will be under a mountain, with an adjoining plateau for a residential area. A commercial district will be at the foot of the mountain.

Wanted a double track mainline to run Amtrak on one, with freight on the other. Then a simple switching area. To facilitate the participation of my 4-year old grandson, I added a trolley line in a figure 8. Its justification is bringing town folk to the mainline passenger station. The only industry is the cement plant. I don't think that I can squeeze in another industry.

So, I temporarily wired everything to see how the DCC would work out. It's still just as flaky as ever. I do think that I fried one decoder. I've decided to abandon it and go back to reliable (for me, anyway) DC. Did learn that the fun part of DCC was the sounds of the engine. The one working engine works well under DC, with sounds and light all functioning. I'm going to replace the decoder in the other one, sometime in the future.

I thought of going to the old block system until I figured out that Kato's power routing switches are a great way to control movement. Of course, this layout will need multiple DC controllers: one for each mainline, one for the inner switching area, and one more for the trolley line.

Once all the wiring is complete and tested, it'll be tunnel and town time. Hopefully it won't take another year.