narrowgauger

New Member

Hello,

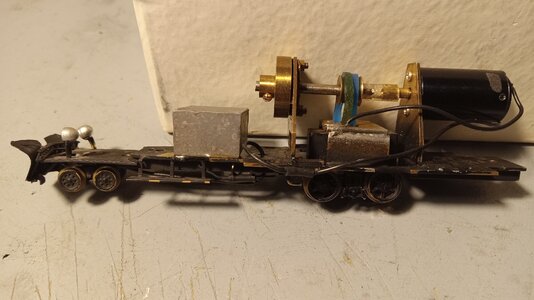

I am in need of information about a brass HOn3 model of a #2 RGS galloping goose. It is made by Balboa and the question concerns how to repair the somewhat archaic "rubber band" drive. I need to replace the rubberband/belt and there doesn't seem to be an easy way to disassemble the gearbox. The bottom plate looks as if it is attached to the frame at the 4 corners by soldering it to the frame. Does anyone know if that is the only way to get the new band installed or am I missing something obvious? Any help would be greatly appreciated. I have included a couple of pictures.

Thanks

John T.

I am in need of information about a brass HOn3 model of a #2 RGS galloping goose. It is made by Balboa and the question concerns how to repair the somewhat archaic "rubber band" drive. I need to replace the rubberband/belt and there doesn't seem to be an easy way to disassemble the gearbox. The bottom plate looks as if it is attached to the frame at the 4 corners by soldering it to the frame. Does anyone know if that is the only way to get the new band installed or am I missing something obvious? Any help would be greatly appreciated. I have included a couple of pictures.

Thanks

John T.