You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chain Link Fencing

- Thread starter wombat457

- Start date

ModelRailroadForums.com is a free Model Railroad Discussion Forum and photo gallery. We cover all scales and sizes of model railroads. Online since 2002, it's one of the oldest and largest model railroad forums on the web. Whether you're a master model railroader or just getting started, you'll find something of interest here.

Who,

Tony, or Boomer?

Also, when soldering your posts and rails, give a go at putting a tiny blob of solder on the tip before you touch it to the wanted joint. Those post and rails do not have much mass and should heat up rather quickly and not cool off the tip enough to cause grief. End result would be less filing and you still would have a good mechanical joint.

Later

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website (Learn More Here)

migalyto

Well-Known Member

He makes it look quite easy, but I'll stick to cheating thanks.

Who,

Tony, or Boomer?

Smudge617

Well-Known Member

Smudge617

Well-Known Member

That sounds like a man with a plan.Ohh, I'm stayin' outta this all together

wombat457

I'm the one

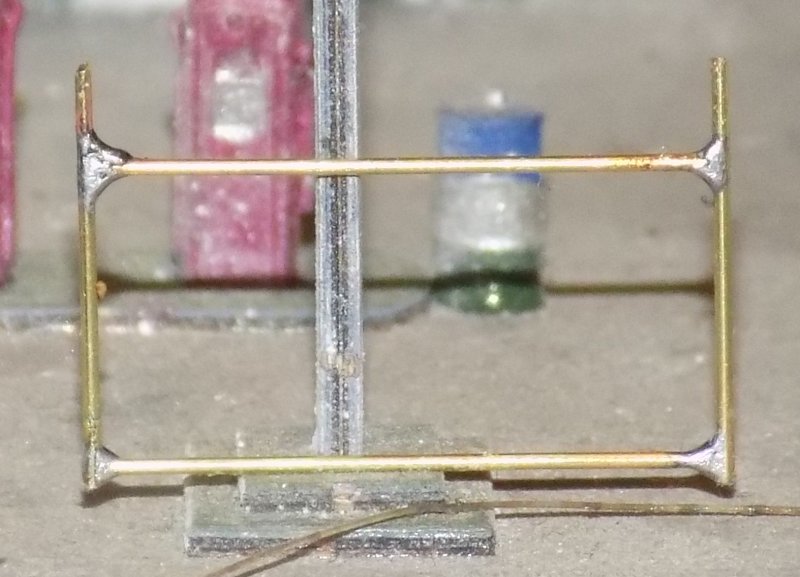

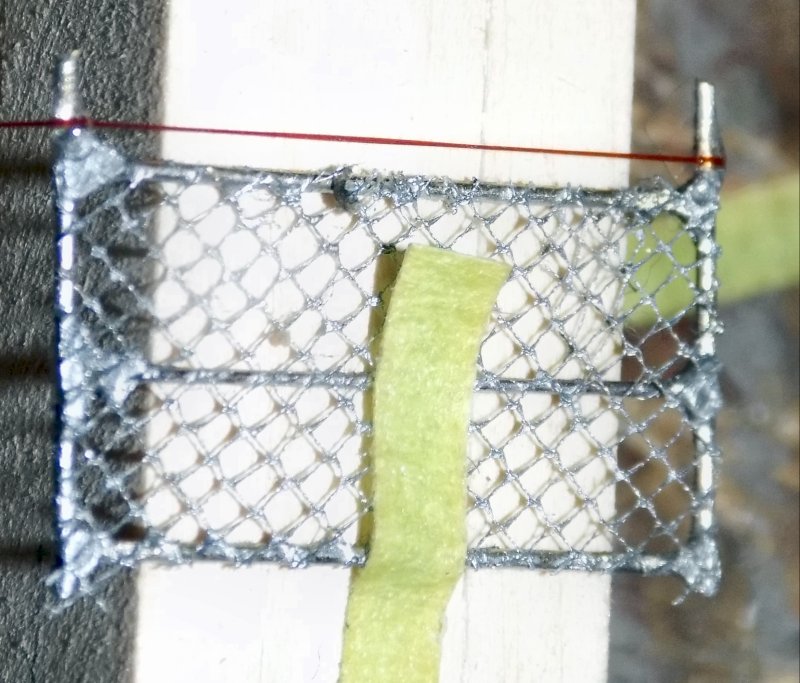

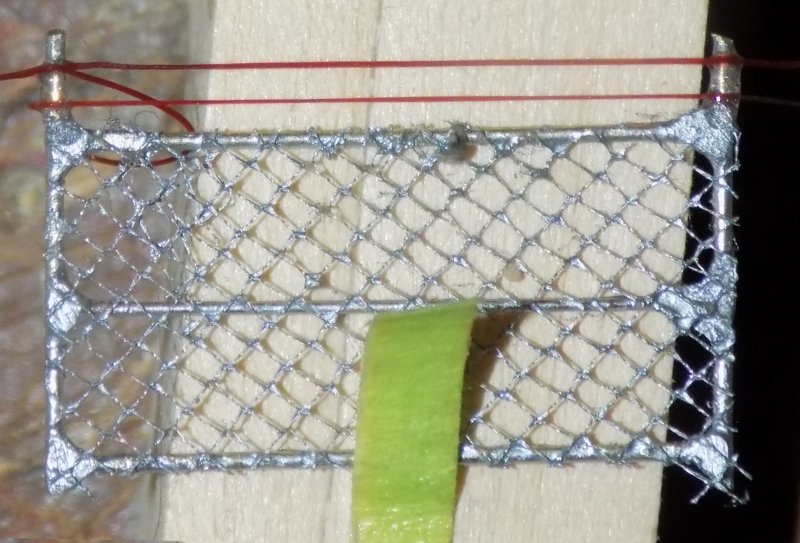

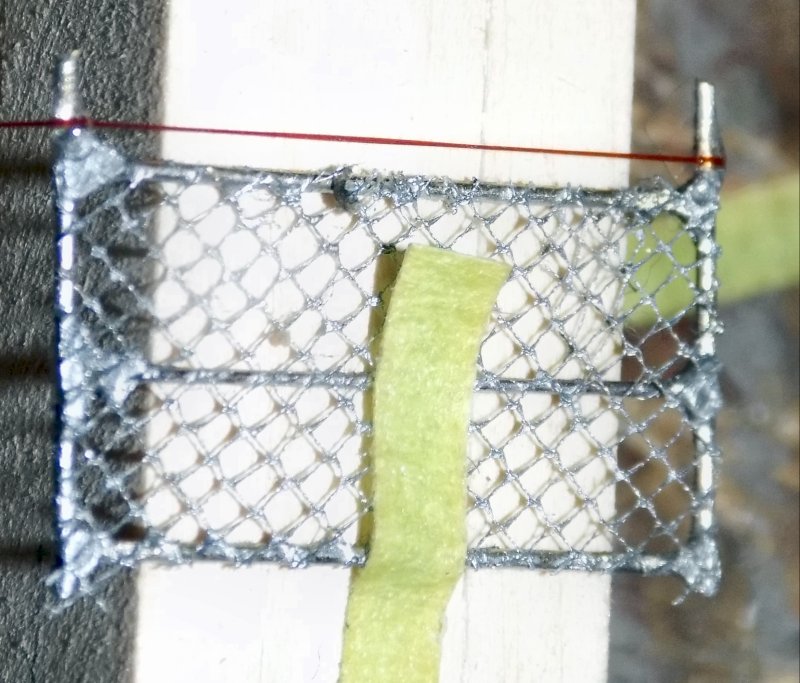

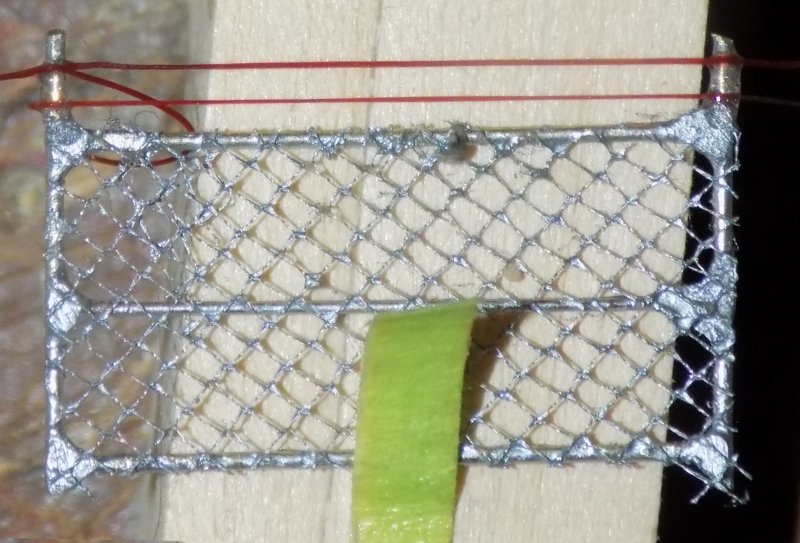

So moving along a little - I completed the "gate mesh" and have started putting in the "Top Wiring" using this EZ-Line. It will look better when sprayed Silver Leaf I believe, OR, I can leave it rusted ??

And a Second Strand:

I* intended to have three strands but the second one kept slipping off of the sold joint

And a Second Strand:

I* intended to have three strands but the second one kept slipping off of the sold joint

Last edited:

Snowman

Well-Known Member

I've been thinking about your project, and I came across this "thick body CA": https://starbond.com/products/thick-ca-glue-em-2000

It's available on Amazon (but a bit pricier I think), as well as from several other brands.

I wonder if a single tiny drop might fill the gap between your tulle material and frame enough to get it where you want it, but not spread out like a thin CA would. To stick in just the one small spot, but not wick out along the "wire," so to speak.

It's available on Amazon (but a bit pricier I think), as well as from several other brands.

I wonder if a single tiny drop might fill the gap between your tulle material and frame enough to get it where you want it, but not spread out like a thin CA would. To stick in just the one small spot, but not wick out along the "wire," so to speak.

Snowman

Well-Known Member

Another thought, and if someone who knows more about this wants to chime in, or even correct me, I'm all ears: Silver solder. The melting point is a higher, but I have the idea it makes a MUCH stronger joint than does conventional solder. Enough so that--this really surprised me--even BANDSAW blades can be rejoined successfully using only silver solder.

I'm posting this one just to show how strong silver solder joints can be. I THINK they can make a smaller joint a lot stronger, but using a lot less solder (I'd try the smallest diameter I could find and work upward as required)

I also recall resistance soldering tools can make smaller joints than other methods, but even using high heat, like you might get using a propane torch.

I'm posting this one just to show how strong silver solder joints can be. I THINK they can make a smaller joint a lot stronger, but using a lot less solder (I'd try the smallest diameter I could find and work upward as required)

I also recall resistance soldering tools can make smaller joints than other methods, but even using high heat, like you might get using a propane torch.

ctclibby

Well-Known Member

Snowman: Yes, Silver Solder has a higher melting point - somewhere close to 1800F, whereas 60/40 starts to melt about 350F. When working with ( very ) small things I suspect that getting temp up for the SS to melt it could dis-color stuff near by and will also melt some of the other joints no matter what you use for a heat sink. Besides Silver, SS has Zinc and Copper which should be stronger than regular solder with Tin and Lead.Another thought, and if someone who knows more about this wants to chime in, or even correct me, I'm all ears: Silver solder. The melting point is a higher, but I have the idea it makes a MUCH stronger joint than does conventional solder. Enough so that--this really surprised me--even BANDSAW blades can be rejoined successfully using only silver solder.

I'm posting this one just to show how strong silver solder joints can be. I THINK they can make a smaller joint a lot stronger, but using a lot less solder (I'd try the smallest diameter I could find and work upward as required)

I also recall resistance soldering tools can make smaller joints than other methods, but even using high heat, like you might get using a propane torch.

Also, when soldering your posts and rails, give a go at putting a tiny blob of solder on the tip before you touch it to the wanted joint. Those post and rails do not have much mass and should heat up rather quickly and not cool off the tip enough to cause grief. End result would be less filing and you still would have a good mechanical joint.

Later

Snowman

Well-Known Member

Before I go anywhere else with this, let me apologize in advance, Wombat, for (once again, as with all-too-many others) hi-jacking your thread. It's just that, with me anyway, one train of thought leads to another (sorry for the "train" thing too). My brain just works that way.

@ctclibby Great info, thanks. As far as discoloring--bluing--I've seen that, yes, even on chrome finished golf club shafts, and in those cases the heat source is only a handheld propane torch. It only has to be hot enough to melt and separate epoxy joints for reshafting...yadda yadda yadda...clubs.

If one is overpainting with a silver (or grey galvanized) color as Wombat is this shouldn't matter, of course.

@ctclibby Great info, thanks. As far as discoloring--bluing--I've seen that, yes, even on chrome finished golf club shafts, and in those cases the heat source is only a handheld propane torch. It only has to be hot enough to melt and separate epoxy joints for reshafting...yadda yadda yadda...clubs.

If one is overpainting with a silver (or grey galvanized) color as Wombat is this shouldn't matter, of course.

Affiliate Disclosure: We may receive a commision from some of the links and ads shown on this website (Learn More Here)