DJ_N_Scaler

New Member

Hello to all,

I'm new here, so hopefully, I'm in the right section!

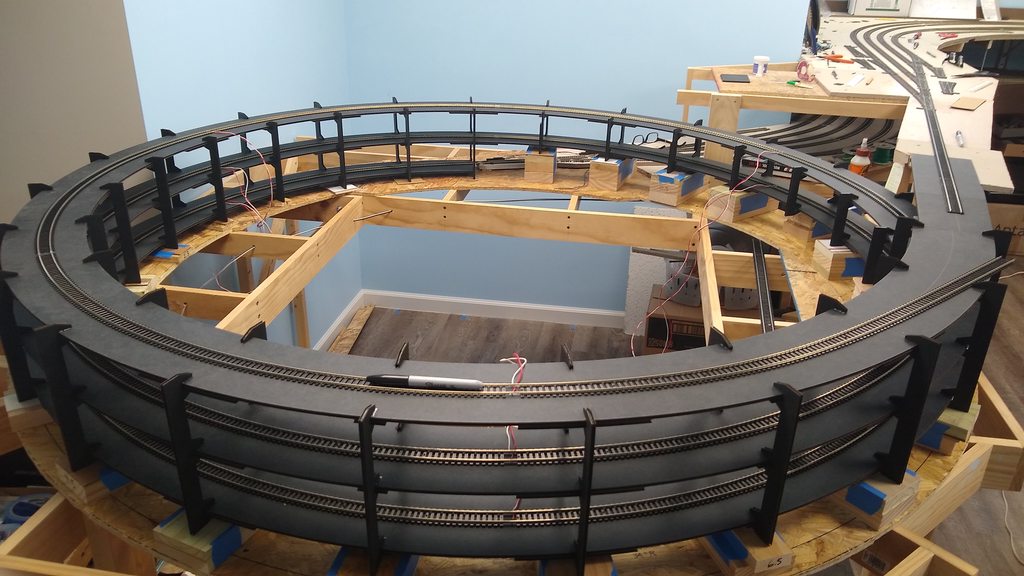

Does anyone have any thoughts on the helix kits from trackside scenery.

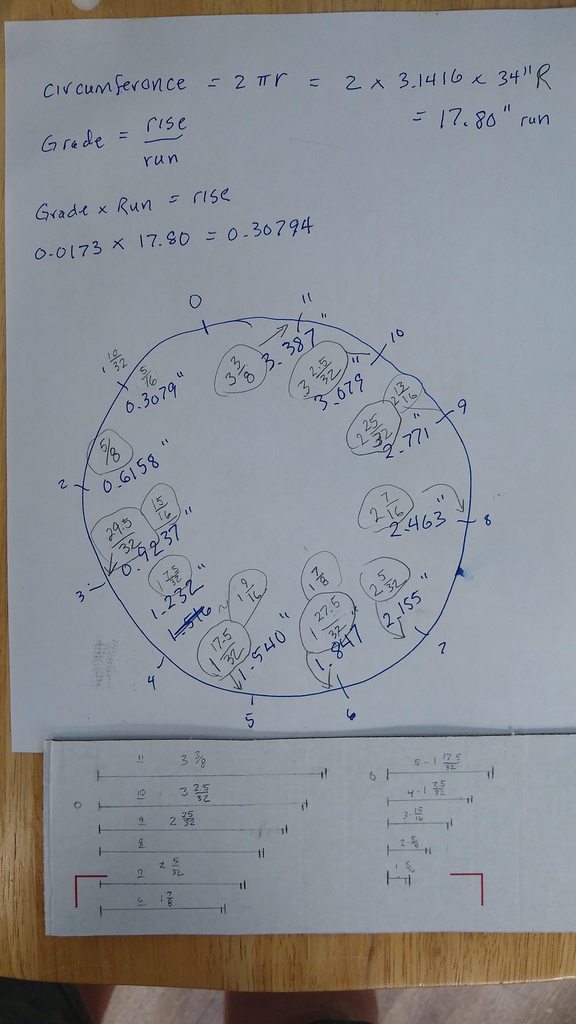

I'm having trouble understanding how fixed spaced risers can effectively create.

a Helix. It seems to me, for every level, there should be a smooth transition between the

notches that hold the base of the level. Their risers appear to be identical with no gradual.

incline per riser. I contacted the seller, but they kept explaining how a helix works, but the real question, above,

was not answered.

Appreciate your thoughts.

I'm new here, so hopefully, I'm in the right section!

Does anyone have any thoughts on the helix kits from trackside scenery.

I'm having trouble understanding how fixed spaced risers can effectively create.

a Helix. It seems to me, for every level, there should be a smooth transition between the

notches that hold the base of the level. Their risers appear to be identical with no gradual.

incline per riser. I contacted the seller, but they kept explaining how a helix works, but the real question, above,

was not answered.

Appreciate your thoughts.