KB02

Well-Known Member

Yes, I have been doing as much research a I can to figure this out and I have found that this means there is a short in the system. I have even figured out exactly WHERE the short is on my layout. I just need help in figuring out a solution.

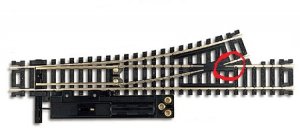

HO Scale - Prodigy Express - Atlas Snap Switch Turnouts. (yes... yes.. I know that the simple fact that I have snap switches is a problem in an of itself... but please read on...).

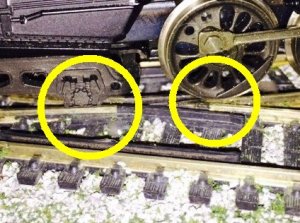

When running my trains across this turn out, I tend to get a short. The short comes when metal wheels cross the frog (see circled area in image below). Even though the rails are eclectically isolated, the wheels are wide enough that they can pull a small spark from the other rail and cause the short. I then get the SVdA error code on my handset and can no longer control the trains (the trains DO, however, keep running... I just can't control them).

I found this on another forum from 2002 so I know it must be a known issue:

http://cs.trains.com/mrr/f/11/p/110552/1276803.aspx

A.) Would this work?

B.) Would I be able to just cut a gap in one of the rails to cut power from the tip at the frog to prevent the short?

C.) I have also seen mentions of using a 12 tail light bulb to prevent the short from effecting the control unit, but I can't quite wrap my head around how that works. (can anyone here explain it a little better?)

HO Scale - Prodigy Express - Atlas Snap Switch Turnouts. (yes... yes.. I know that the simple fact that I have snap switches is a problem in an of itself... but please read on...).

When running my trains across this turn out, I tend to get a short. The short comes when metal wheels cross the frog (see circled area in image below). Even though the rails are eclectically isolated, the wheels are wide enough that they can pull a small spark from the other rail and cause the short. I then get the SVdA error code on my handset and can no longer control the trains (the trains DO, however, keep running... I just can't control them).

I found this on another forum from 2002 so I know it must be a known issue:

http://cs.trains.com/mrr/f/11/p/110552/1276803.aspx

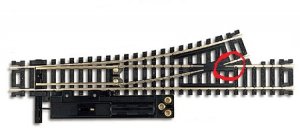

Momentary shorts at insulated frogs are known to happen occasionally with Peco Insulfrog turnouts. Back before Pecos were in common use, the same thing would happen on occasion with Atlas turnouts, particularly #6's. I'm not sure the problem carried over to the code 83 and later versions of the Atlas turnouts.What happens is a metal wheel spans the 2 rails that form the frog point, where they first become "live". The 2 rails are of opposite polarity, and are quite close to each other. This only happens momentarily, as the momentum of the train carries the wheel past the point where it can short. In your case... the Prodigy Express does register the momentary short circuit.

My suspicions are reinforced by your statements that it only happens at 2 turnouts, and only with particular wheels, and then not all the time.

To test/temporarily fix, coat the first 1/2" of live rail beyond each frog point with nail polish. Only do this to the 2 offending turnouts. Allow to dry and test. If I'm wrong, remove the nail polish, and no harm is done. If I'm right, you will have to recoat the nail polish occasionally or remove some of the rail head on the inside of the frog point so that the wheels can't short across the 2 rails. I would also check the wheel gauging with an NMRA gauge - chances are the offending wheels will also be slightly wide in gauge.

HTH

Fred W

A.) Would this work?

B.) Would I be able to just cut a gap in one of the rails to cut power from the tip at the frog to prevent the short?

C.) I have also seen mentions of using a 12 tail light bulb to prevent the short from effecting the control unit, but I can't quite wrap my head around how that works. (can anyone here explain it a little better?)