montanan

Whiskey Merchant

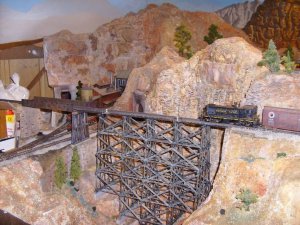

That was a nice series of photos on the trestle build. Well done.

Interesting that you should bring up R/C aircraft. I have been flying since I was 16 and when my kids were growing up they loved to go flying and then insisted on having an R/C plane for them to fly. We did go the ready to fly route and after a few minor mishaps, the became quite good at flying them. Never wrecked one that wasn't a quick fix to get back into the air. Yers back there was a hobby shop of sorts in the area and they did carry some model railroad supplies such ads RTR freight cars and locomotives along with some Woodland Scenic products, but the R/C aircraft and R/C cars soon took over the shop and away went anything for model railroad.

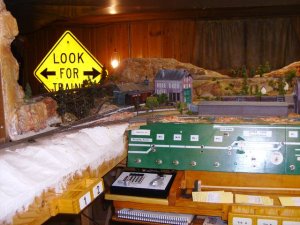

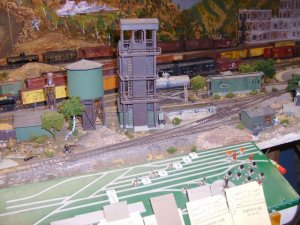

Enjoying your layout photos.

Interesting that you should bring up R/C aircraft. I have been flying since I was 16 and when my kids were growing up they loved to go flying and then insisted on having an R/C plane for them to fly. We did go the ready to fly route and after a few minor mishaps, the became quite good at flying them. Never wrecked one that wasn't a quick fix to get back into the air. Yers back there was a hobby shop of sorts in the area and they did carry some model railroad supplies such ads RTR freight cars and locomotives along with some Woodland Scenic products, but the R/C aircraft and R/C cars soon took over the shop and away went anything for model railroad.

Enjoying your layout photos.