Waaaayyy back in 2012 I made a post about a possible Tortoise alternative. Soon after that, real life took me out of model railroading and all sorts of other "distractions". Now that I am nearing retirement, I am back at it. This time with several RR products that might be of interest. If there is, I will go ahead and persue them.

ALL of these products are "smart" in that they have microcontrollers in them. They are all wireless too (Bluetooth and WiFi). They are configurable via a Bluetooth app on your phone. They can be used by the full range of railroader, from the DC and push-button user through DCC. They can also all be controlled via a WiFi network.

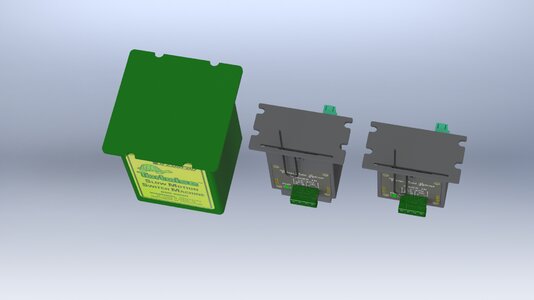

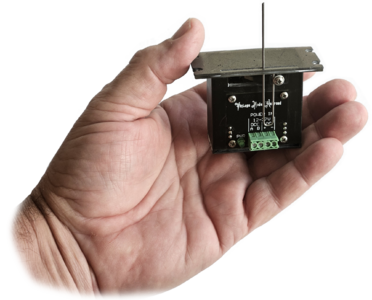

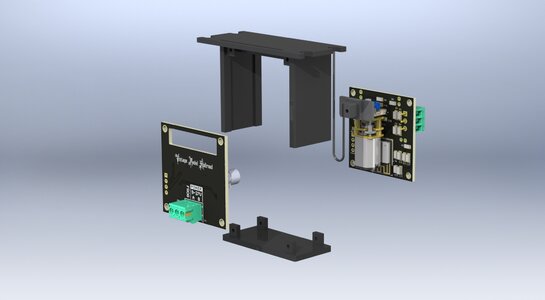

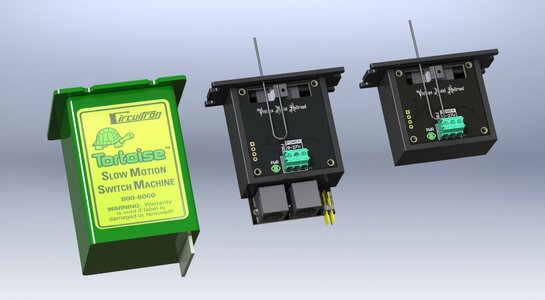

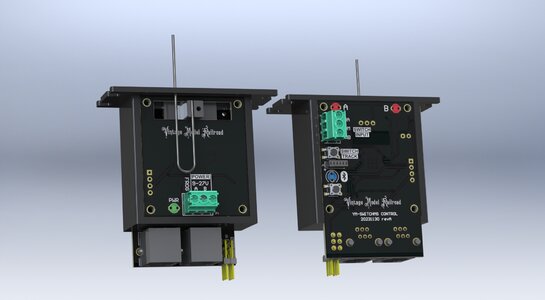

YM-SwitchM

As you can see from the attached file, all of these are in design. Prototypes of the YM-SwitchMS are already functional. The parts for the YM-SwitchM are on the way. I would greatly appreciate your input about these products. Feel free to suggest more features.

Thanks very much.

ALL of these products are "smart" in that they have microcontrollers in them. They are all wireless too (Bluetooth and WiFi). They are configurable via a Bluetooth app on your phone. They can be used by the full range of railroader, from the DC and push-button user through DCC. They can also all be controlled via a WiFi network.

YM-SwitchM

- Uses a silent gear motor (not a servo)

- .57" of direct travel (no fulcrum needed)

- Completely configurable via app (travel limits, travel speed, default position, go to center)

- Powered by DC or DCC track

- Indicator lights showing which position the switch is in

- Push-button that toggles the switch from one position to the other

- Same as the above but it includes control of six signals

- Signals can be individually "mapped" to either switch position to be on, off, flashing

- Flash rate is configurable

- Controls two gates and up to 12 signals

- Supports input from four sensors (IR or photocell)

- Built-in audio amp and speaker connections for crossing sounds

- Controls up to 24 signals

- Signals can be independently controlled (On, Off, Flashing)

- Powered by track voltage (DC or DCC), an auxillary power input, or an internal 5V supply

- An extension board that adds an additional 24 signals

- Can be stacked for an unlimited number of signals

As you can see from the attached file, all of these are in design. Prototypes of the YM-SwitchMS are already functional. The parts for the YM-SwitchM are on the way. I would greatly appreciate your input about these products. Feel free to suggest more features.

Thanks very much.