Trucklover

BNSF SD70MAC's

Hi guys, here is the tutorial i have been saying i would be doing for the past few months

Ive had several people ask me how i did my roads and crossings from this picture:

Well this tutorial will not include any pictures of doing a crossing, but after i finish this post on doing regular roads, i will do another post in this thread explaining how i did my crossing in the picture above with Woodland Scenics Smooth-It.

Before i begin, id like to not that

USING WOODLAND SCENICS SMOOTH-IT TAKES PATIENTS!

Please don't hold me responsible for your roads not turning out the way you would like them to when following this tutorial

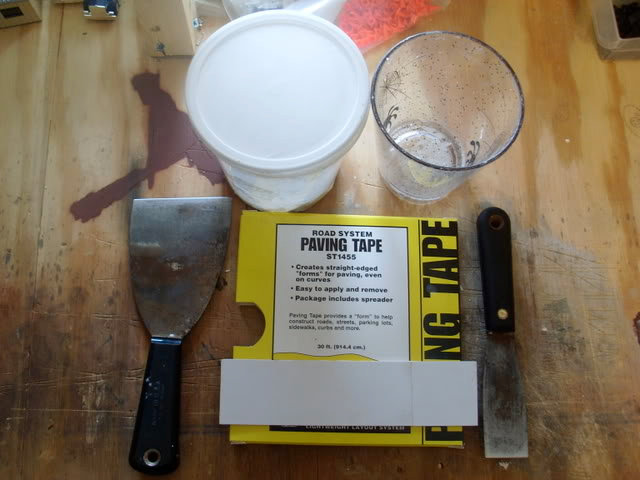

TOOLS YOU NEED TO DO THIS:

1. Woodland Scenics Smooth-It

2. Woodland Scenics Paving Tape

3. Some kind of spreader (i used one that came with a package of paving tape and modified it to make it longer, see picture below)

4. 3/4" Putty Knife

5. 3" Putty Knife

6. A mixing container with a lid

7. A large cup of water

8. Steel Ruler

9. A Sharpie or other pen or pencil

The modified spreader i listed above in the tools was made from 2 spreaders. Each package of Paving Tape includes a spreader, i took 2 of these (i have multiple packages of Paving Tape) and added 1-3/4" from the second spreader onto the first spreader, making it a total length of 7" and easier to do a highway or road. You can make the spreader however long you want to, i would just keep it under 9". 7" is long enough to do a 3 lane road, 8" would be just long enough to do a 4 lane road (lanes of 1-3/4" wide).....

The 2 different sizes of Putty Knifes in addition to the lengthened spreader, make the road laying much easier, i would highly suggest getting both sizes of Putty Knifes. The Putty Knifes are mostly used for after the first coat is dry. The smaller one is good for small spaces or one lane roads, the larger for smoothing larger roads....

The mixing container is very important, and i would try and find one with a lid. The cup of water is also important, this is your cleaning cup, where you clean the spread and putty knifes.

If you have all of the above, you should be off to a good start.

Laying your Roads/Highways With Paving Tape

It is important to plan your Roads and or Highways. I would suggest taking your Steel Ruler and actually drawing out a path for the road with the Sharpie or whatever your using. Curves can be difficult, but if you keep a consistent width of the road through the curve, it will come out just fine. Measure out and draw your roads on your layout base. Be sure to include the center dividers if you would want a divided road/highway.

Here is a guideline from the back of the Woodland Scenics Paving Tape Package on road widths:

Prototype City Street = 30' wide. HO Scale = 4-1/8" wide. N Scale = 2-1/4" wide.

Prototype Country Road = 18' wide. HO Scale = 2-1/2" wide. N Scale = 1-3/8" wide.

Prototype Highway Lanes = 12-18' wide depending on the era being modeled. HO Scale = 1-5/8" - 2-1/2" wide. N Scale = 7/8" - 1-3/8" wide.

Prototype Side Walk = 4' wide. HO Scale = 1/2" wide. N Scale = 1/4" wide.

I made my highway lanes 1-3/4" wide, this was only done to try and save a little space, otherwise i would have done them 2-1/2" wide. I test fitted 3 of my trucks side by side and they fit comfortably along side each other on the highway, so 1-3/4" works just fine.

After you have the path of the road marked out, take the Paving Tape, peal some of the backing off so the sticky side is exposed, and lay it along the lines of the road that you drew out. If your doing a regular 4 lane highway, make sure your spreader reaches all the way across to the other side of the road where the other strip of Paving Tape is, this is very important. If i does not, either modify your Spreader to make it longer or lay another strip of Paving Tap down the center of the 2 strips of Paving Tape you have already laid for the roads edges. Once the first coat of Smooth-It has dried, you will have to remove the center Paving Tape Strip and fill it in with more Smooth-It....

I would also suggest that if you are doing a long and wide road, break it up into sections. You can draw all the lines for the road but only lay Paving Tape in sections, this will be alot easier in the long run.

Here is how i laid my Highway out with the Paving Tape, as you can see, this particular section, i had to make the right side of the highway narrow down to 1 lane so that i would have room to put in the on-ramp on the left side, so that is why it goes from a 6 lane highway with a center divider to a 4 lane highway with a center divider, the other 2 lanes would be just off the layout....

Now that you have your roads marked and the Paving Tape down for the roads edges, you are ready to mix and pour the Smooth-It

Ive had several people ask me how i did my roads and crossings from this picture:

Well this tutorial will not include any pictures of doing a crossing, but after i finish this post on doing regular roads, i will do another post in this thread explaining how i did my crossing in the picture above with Woodland Scenics Smooth-It.

Before i begin, id like to not that

USING WOODLAND SCENICS SMOOTH-IT TAKES PATIENTS!

Please don't hold me responsible for your roads not turning out the way you would like them to when following this tutorial

TOOLS YOU NEED TO DO THIS:

1. Woodland Scenics Smooth-It

2. Woodland Scenics Paving Tape

3. Some kind of spreader (i used one that came with a package of paving tape and modified it to make it longer, see picture below)

4. 3/4" Putty Knife

5. 3" Putty Knife

6. A mixing container with a lid

7. A large cup of water

8. Steel Ruler

9. A Sharpie or other pen or pencil

The modified spreader i listed above in the tools was made from 2 spreaders. Each package of Paving Tape includes a spreader, i took 2 of these (i have multiple packages of Paving Tape) and added 1-3/4" from the second spreader onto the first spreader, making it a total length of 7" and easier to do a highway or road. You can make the spreader however long you want to, i would just keep it under 9". 7" is long enough to do a 3 lane road, 8" would be just long enough to do a 4 lane road (lanes of 1-3/4" wide).....

The 2 different sizes of Putty Knifes in addition to the lengthened spreader, make the road laying much easier, i would highly suggest getting both sizes of Putty Knifes. The Putty Knifes are mostly used for after the first coat is dry. The smaller one is good for small spaces or one lane roads, the larger for smoothing larger roads....

The mixing container is very important, and i would try and find one with a lid. The cup of water is also important, this is your cleaning cup, where you clean the spread and putty knifes.

If you have all of the above, you should be off to a good start.

Laying your Roads/Highways With Paving Tape

It is important to plan your Roads and or Highways. I would suggest taking your Steel Ruler and actually drawing out a path for the road with the Sharpie or whatever your using. Curves can be difficult, but if you keep a consistent width of the road through the curve, it will come out just fine. Measure out and draw your roads on your layout base. Be sure to include the center dividers if you would want a divided road/highway.

Here is a guideline from the back of the Woodland Scenics Paving Tape Package on road widths:

Prototype City Street = 30' wide. HO Scale = 4-1/8" wide. N Scale = 2-1/4" wide.

Prototype Country Road = 18' wide. HO Scale = 2-1/2" wide. N Scale = 1-3/8" wide.

Prototype Highway Lanes = 12-18' wide depending on the era being modeled. HO Scale = 1-5/8" - 2-1/2" wide. N Scale = 7/8" - 1-3/8" wide.

Prototype Side Walk = 4' wide. HO Scale = 1/2" wide. N Scale = 1/4" wide.

I made my highway lanes 1-3/4" wide, this was only done to try and save a little space, otherwise i would have done them 2-1/2" wide. I test fitted 3 of my trucks side by side and they fit comfortably along side each other on the highway, so 1-3/4" works just fine.

After you have the path of the road marked out, take the Paving Tape, peal some of the backing off so the sticky side is exposed, and lay it along the lines of the road that you drew out. If your doing a regular 4 lane highway, make sure your spreader reaches all the way across to the other side of the road where the other strip of Paving Tape is, this is very important. If i does not, either modify your Spreader to make it longer or lay another strip of Paving Tap down the center of the 2 strips of Paving Tape you have already laid for the roads edges. Once the first coat of Smooth-It has dried, you will have to remove the center Paving Tape Strip and fill it in with more Smooth-It....

I would also suggest that if you are doing a long and wide road, break it up into sections. You can draw all the lines for the road but only lay Paving Tape in sections, this will be alot easier in the long run.

Here is how i laid my Highway out with the Paving Tape, as you can see, this particular section, i had to make the right side of the highway narrow down to 1 lane so that i would have room to put in the on-ramp on the left side, so that is why it goes from a 6 lane highway with a center divider to a 4 lane highway with a center divider, the other 2 lanes would be just off the layout....

Now that you have your roads marked and the Paving Tape down for the roads edges, you are ready to mix and pour the Smooth-It

Last edited by a moderator: