I'm not trying to ring alarm bells or anything, but I am saying the pink and blue extruded insulating foam is not as stable as plywood. I am pointing this out because after spending a couple thousand dollars building these modules, I want them to be dimensionally stable. I don't want to have to rebuild and tear up lots of scenery again. It gets expensive. I've been building layouts and modules for thirty years, so I have some relevant experience. I am reporting both my own experience and the experiences several people who built Free-mo modules have had after laying roadbed and track directly on pink and blue foam.

I can't speak for everyone with these problems, but my modules are stored indoors. The shrinkage is caused by outgassing of the chemical vapors trapped inside the foam. Some of what I've read points to the pink foam specifically, but one of my friends used 2" thick blue foam and had similar problems. Fortunately, his modules are straight so alignment hasn't been a problem. Where the problems crop up for us is at the endplate. The track has to be perpendicular to the end of the module so that when we join two modules together, the track continues in a straight line from module to module. When the track is kicked out of alignment from the endplate, you will have an angular bend in the rails at the module joint, which could present a problem for operating if the angle is bad enough.

Generally, there isn't much of a problem with straight modules, but you may notice over time - again it takes years - some shrinkage in the foam where the foam edges have detached from the plywood frame. Where it becomes a real problem is on curved modules, especially those curves built at a minimum radius. Not only does the foam pull away from the edges, it squeezes the track tighter into the curve that was originally laid. If you were to make a repair to the track and had to cut one of the rails, the tension in the rail that's released when the rail is cut would surprise you. This track is laid at a moderate temperature and not under any kind of tension, so the tension clearly comes from contraction of the base layer.

Since we have noticed this problem and since careful measurements of modules are key to planning a large setup, we regularly measure our modules along all sides and diagonally to get the actual shape and dimensions of each module. It is through these measurements we have been able to determine the module frames themselves, which are constructed of 3/4" birch plywood (a very stable material), are not expanding away from the edges of the foam. The foam is contracting inside the module frame.

Our Free-mo group has a large multiple section module from Minnesota as well as several locally constructed modules (we're in Texas). We've set up our modules with other groups in South Dakota, Kansas, Oklahoma and Texas with groups who brought modules from Kansas, Nebraska, Colorado, Oklahoma and Texas. The shrinkage problem is widespread among the various groups, so I don't think it's a problem related to geography.

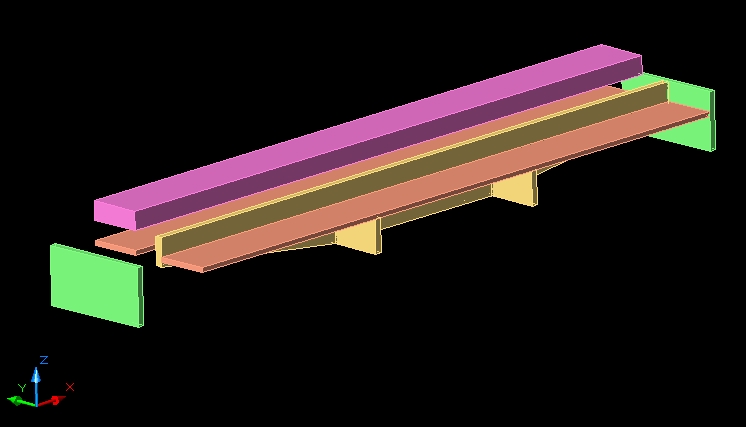

The solution going forward for me is to lay track and roadbed on a plywood base. I still strongly advocate using foam as a scenery material, so I'll simply use the foam right up to the edge of the track, but I won't attach it to the foam. Here's an illustration showing a lightweight spline design:

The green parts are 3/4" birch plywood endplates, the light tan is 3/4" plywood, the rose color is 1/2" plywood and the pink is extruded insulating foam (the foam piece on the near side has been omitted for clarity).

On a small home layout, these issues may never come up since you'll probably construct everything on one sheet of foam. Since it will all shrink together, it won't matter much since the shrinkage rate is small. But if you ever expand or go with a different format or even get into modular railroading, be aware of this phenomenon. Free-mo module tolerances are tight to assure compatibility among builders across North America, so for those of us striving to achieve and maintain these standards, this is a very real concern.