Tiddles

New Member

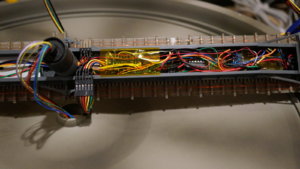

Walthers 130 DCC Turntable PROBLEM. I got this second hand and it did work briefly on DCC. But now all I get is Err1 on the control box. I have tried it on DC and DCC but same problem. I have tested the motor directly and it works ok. I am told that Err1 means no connection between the bridge disk connection and pit brushes but I have checked and cleaned all the contacts. If I connect a DC controller to the two outer ring halves there is power to the bridge track. I have tried to directly connect to the other rings to see if the motor will operate but nothing. The contacts have been cleaned so I suspect a fault with either the control unit or the PCB in the bridge.