Twinwoods & Bedford - 01 - Layout Design

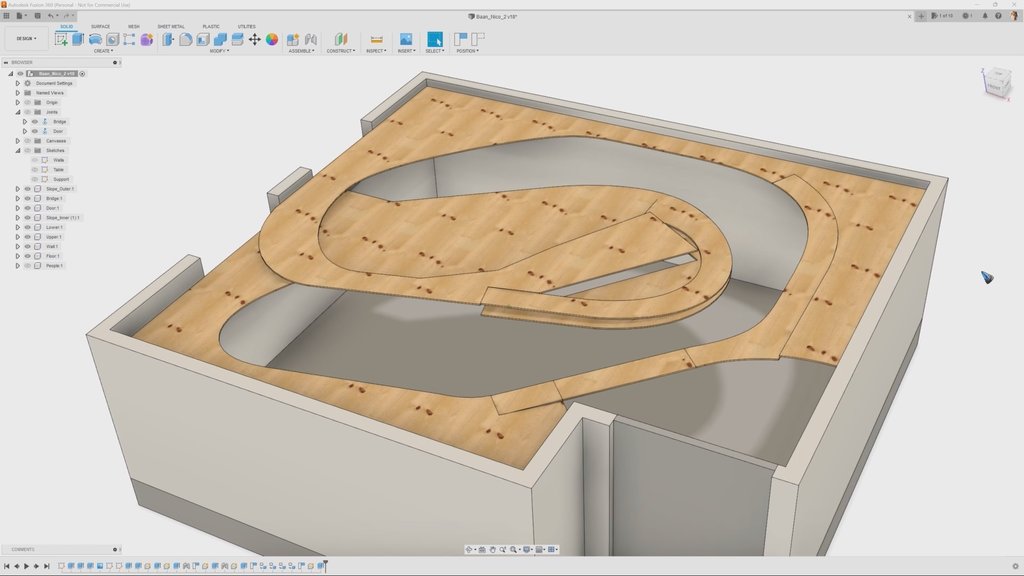

Together with hobby friend Nico the plan is to build a new layout in a spare bedroom. In this thread we like to post progress from time to time. We’ll go through all the steps, from first ideas, to design, to (3D) simulation, to woodwork, to track laying, mount point servo’s, add train feedback and create computer control. The plan is to add some videos along the way too.

No scenery in that list? Well … to be honest, creating beautiful scenery is not our forte. To us the emphasis of the hobby lies on the design, woodwork, track laing and then the automation. We’ll probably drive around with too many trains on too much track to make it look like anything ‘real’.

This is a link to video 01 - Layout Design

These were our criteria:

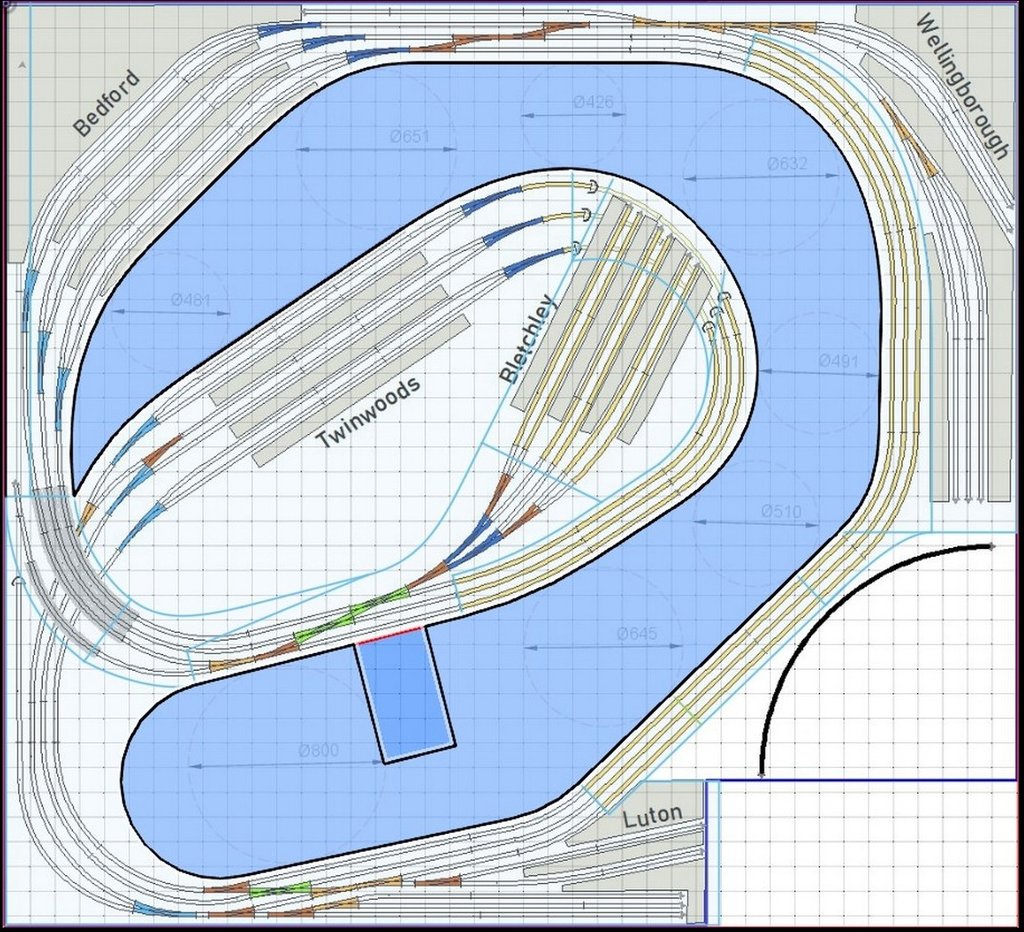

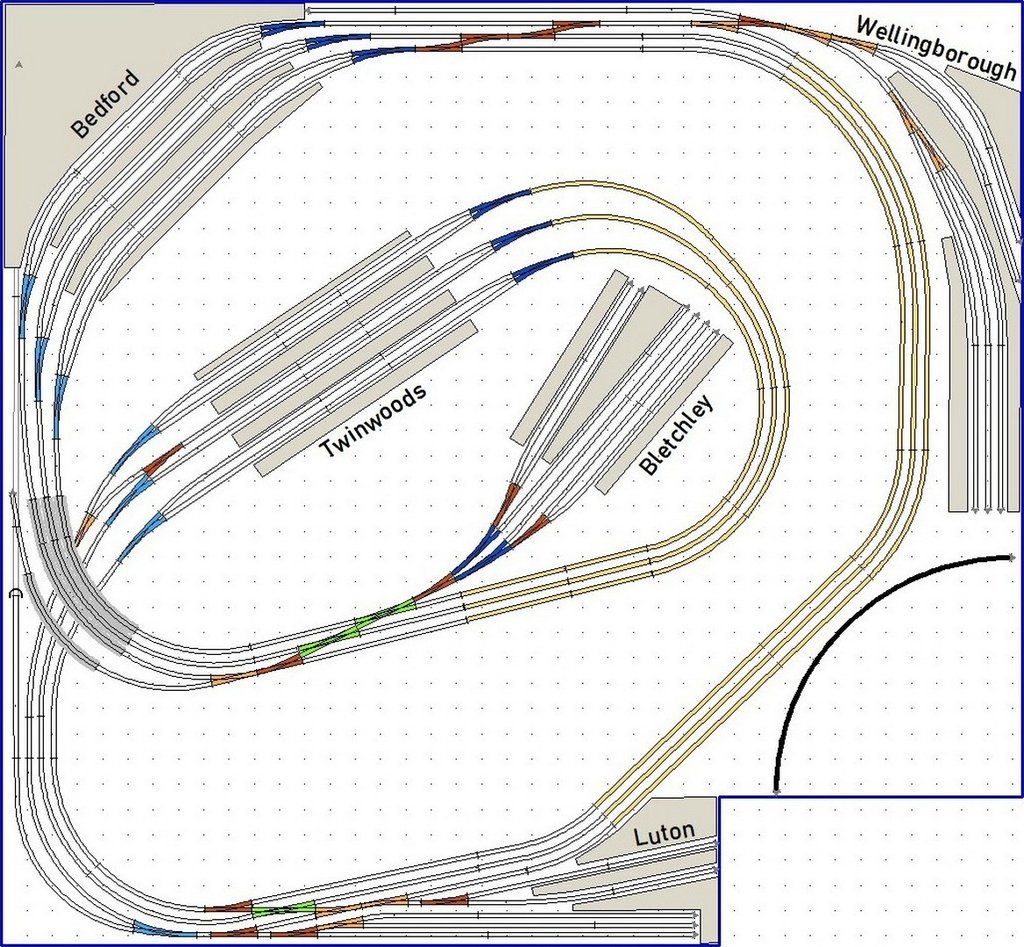

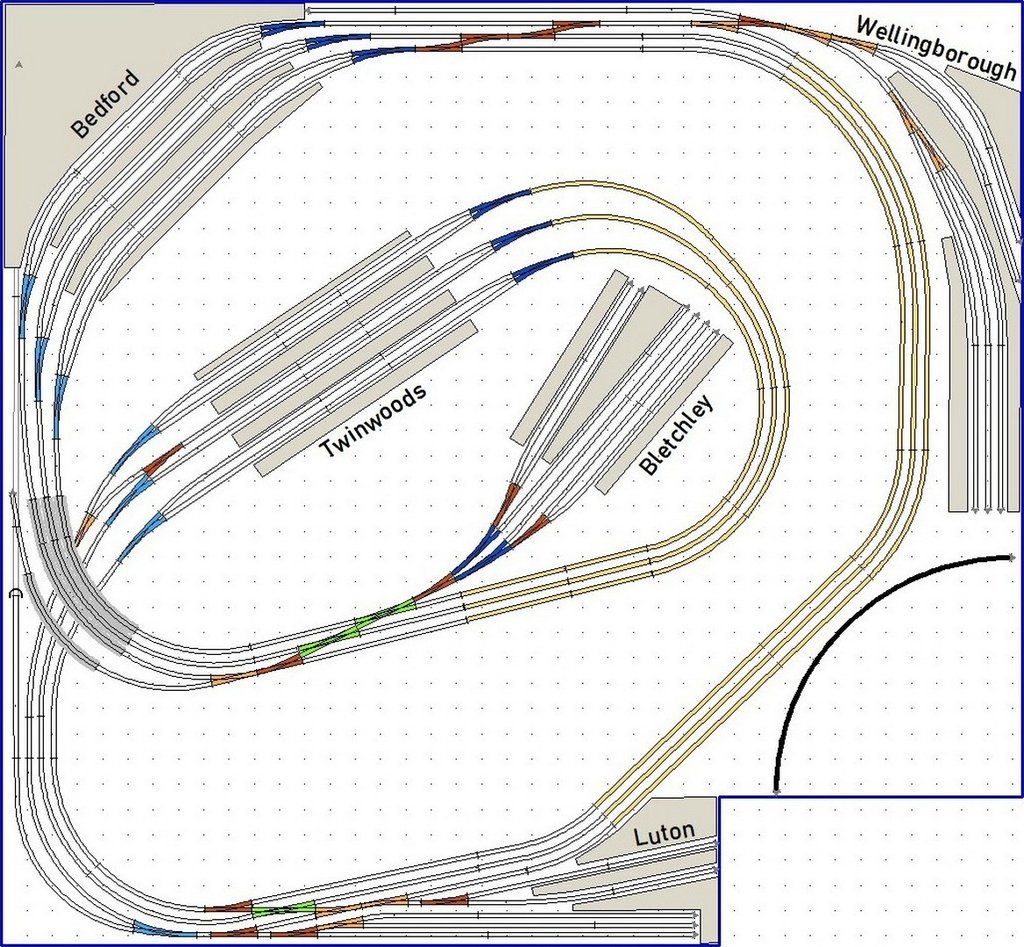

This is the end result of our design efforts:

Together with hobby friend Nico the plan is to build a new layout in a spare bedroom. In this thread we like to post progress from time to time. We’ll go through all the steps, from first ideas, to design, to (3D) simulation, to woodwork, to track laying, mount point servo’s, add train feedback and create computer control. The plan is to add some videos along the way too.

No scenery in that list? Well … to be honest, creating beautiful scenery is not our forte. To us the emphasis of the hobby lies on the design, woodwork, track laing and then the automation. We’ll probably drive around with too many trains on too much track to make it look like anything ‘real’.

This is a link to video 01 - Layout Design

These were our criteria:

- Available space: 4040 x 3700 mm

- Scale: HO

- Rail: Peco OO 75

- Minimum radius: 600 mm

- No need for much scenery

- We like to have a lot of rails

- It doesn’t have to resemble real world

- We like to be able to drive around on a loop

- We also like to drive dead end to dead end

- We like to have a train viaduct, it enables a longer available track in the same space

This is the end result of our design efforts:

Last edited: