Here we go again.

First layout started was a 6x10 donut that got as far as bench work and foam. No roadbed and no track.

Second layout was 6' x 12' with two 1' x 4' staging extensions... also benchwork and foam. But that time I also got started on foam mountains and a tunnel.

Moved again, this time for the last time and needing to start over from scratch.

I have less space to work with this time around, and I think that will be better. I'll actually get to make some progress by concentrating on a smaller area.

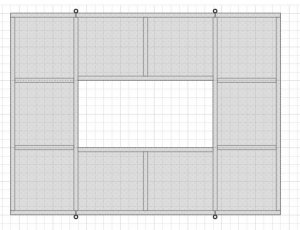

The plan... 6' x 8' donut that I can hoist up and out of the way when not in use.

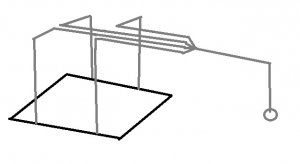

I have a plan to use 2x3 stud boards to frame the table. Then 1 or 2 layers of 1" foam board as the main surface.

This platform will have 4 hoist points (2 along each of the 8' sides) with cables, turnbuckles, and a small boat trailer manual winch to raise and lower the deal. When lowered down, it will rest on 4 detachable legs to provide support and stop it from swinging around.

Question... What size cable should I use to support the layout?

Of course, I'll post some pics as I make progress. Very excited to get rolling.

Thanks,

Doug

First layout started was a 6x10 donut that got as far as bench work and foam. No roadbed and no track.

Second layout was 6' x 12' with two 1' x 4' staging extensions... also benchwork and foam. But that time I also got started on foam mountains and a tunnel.

Moved again, this time for the last time and needing to start over from scratch.

I have less space to work with this time around, and I think that will be better. I'll actually get to make some progress by concentrating on a smaller area.

The plan... 6' x 8' donut that I can hoist up and out of the way when not in use.

I have a plan to use 2x3 stud boards to frame the table. Then 1 or 2 layers of 1" foam board as the main surface.

This platform will have 4 hoist points (2 along each of the 8' sides) with cables, turnbuckles, and a small boat trailer manual winch to raise and lower the deal. When lowered down, it will rest on 4 detachable legs to provide support and stop it from swinging around.

Question... What size cable should I use to support the layout?

Of course, I'll post some pics as I make progress. Very excited to get rolling.

Thanks,

Doug