I'm loosely targeting the late 1800s/very early 1900s granite railroads, specifically in and around Barre, VT, in HO scale - see previous (very very old) thread on building a flat car: https://modelrailroadforums.com/for...-a-late-1800s-flatcar-lots-of-pictures.22382/

It's been pretty easy to find kits to build out older boxcars and such, and I have several Bachmann Spectrum 0-6-0 locos that should do the trick, but I haven't been able to find any cabooses that suited me. I had a handful of spare parts from other builds and sample bags, so I figured maybe I would scratch build one! I drew out some rough sketches but it quickly became apparent that I didn't have enough material to meet the drawing parameters, so I kind of winged it. This turned out to not be such a great idea, but oh well...on to the pics!

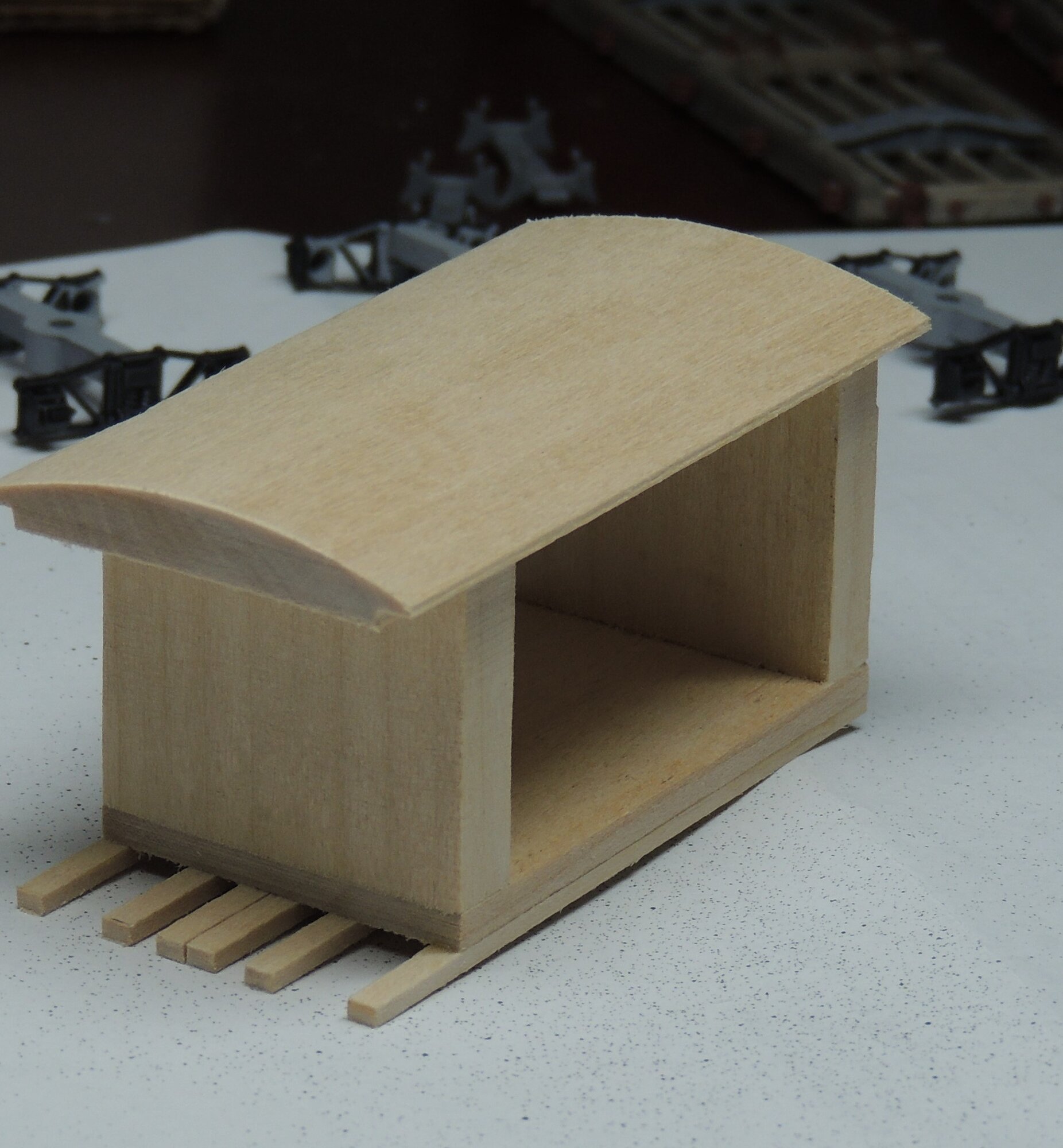

First built the basic box structure. I used a scrap of caboose roof from a Northeastern Scale Lumber sample pack and some misc basswood. Side note - the Perfect Car Kit Construction and Good Car Sides Forever guides from LaBelle Woodworking are REALLY great (and free!) resources - https://www.labellemodels.com/hints-pointers-c-91.html

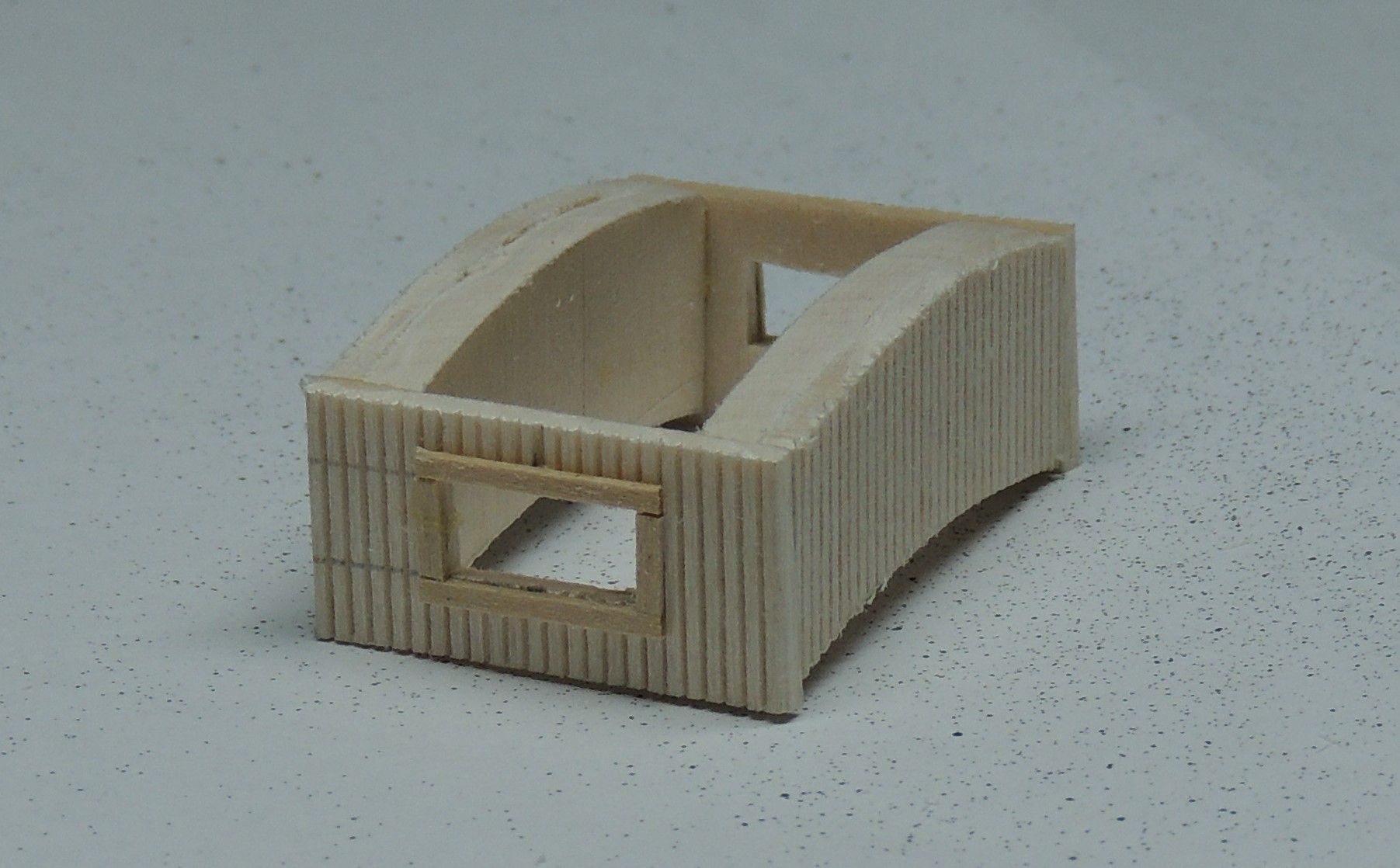

Next up, the cupola. I originally planned to order one from Bitter Creek Models, but they were out of stock so tried to do it myself. This was a HUGE pain, I don't care to think about how long it took. The sides are 1/16" thick (also from Northeastern) which made this possible - I don't think I could have done it with the usual 1/32" stuff you get in kits.

I used the previously mentioned LaBelle guide to glue scraps of siding together endwise, then added some windows. I did the entire top/bottom frame boards as a single unit and then cut out the gaps to avoid having wonky alignment/leveling - this worked pretty well.

Sides on the car, and starting to put some extra details on the end. I got very lucky here in that the windows aligned almost perfectly with the blocks I used for the end of the frame. Again, actual prior planning rather than just winging it probably would have been good! I also remembered just in the nick of time to glue some lead shot inside to bump up the car's weight.

I also remembered just in the nick of time to glue some lead shot inside to bump up the car's weight.

Got the cupola glued in place, and started adding some details. Not sure what I'll do about the windows that face blocks (all those that you can see from this angle). I guess will paint them black to fake it, I definitely don't want any part in trying to cut through that whole block to make them pass through to the interior.

So far I think it looks pretty good, but now that I actually measure it the damn thing is about 13 scale feet tall Probably not remotely prototypical, but as I don't have a prototype, I'm cutting myself some slack!! I suspect it will look weird with other rolling stock but probably will look fine as a standalone piece somewhere on a layout/diorama. Anyway, still a good bit more work to do - I'll add a ladder and brake stave on this end, and perhaps a railing if I can make it work. Finish up the roof walk, and put some grab irons on the other end. Then of course paint and add couplers and trucks. I'll post more pics as I make more progress.

Probably not remotely prototypical, but as I don't have a prototype, I'm cutting myself some slack!! I suspect it will look weird with other rolling stock but probably will look fine as a standalone piece somewhere on a layout/diorama. Anyway, still a good bit more work to do - I'll add a ladder and brake stave on this end, and perhaps a railing if I can make it work. Finish up the roof walk, and put some grab irons on the other end. Then of course paint and add couplers and trucks. I'll post more pics as I make more progress.

It's been pretty easy to find kits to build out older boxcars and such, and I have several Bachmann Spectrum 0-6-0 locos that should do the trick, but I haven't been able to find any cabooses that suited me. I had a handful of spare parts from other builds and sample bags, so I figured maybe I would scratch build one! I drew out some rough sketches but it quickly became apparent that I didn't have enough material to meet the drawing parameters, so I kind of winged it. This turned out to not be such a great idea, but oh well...on to the pics!

First built the basic box structure. I used a scrap of caboose roof from a Northeastern Scale Lumber sample pack and some misc basswood. Side note - the Perfect Car Kit Construction and Good Car Sides Forever guides from LaBelle Woodworking are REALLY great (and free!) resources - https://www.labellemodels.com/hints-pointers-c-91.html

Next up, the cupola. I originally planned to order one from Bitter Creek Models, but they were out of stock so tried to do it myself. This was a HUGE pain, I don't care to think about how long it took. The sides are 1/16" thick (also from Northeastern) which made this possible - I don't think I could have done it with the usual 1/32" stuff you get in kits.

I used the previously mentioned LaBelle guide to glue scraps of siding together endwise, then added some windows. I did the entire top/bottom frame boards as a single unit and then cut out the gaps to avoid having wonky alignment/leveling - this worked pretty well.

Sides on the car, and starting to put some extra details on the end. I got very lucky here in that the windows aligned almost perfectly with the blocks I used for the end of the frame. Again, actual prior planning rather than just winging it probably would have been good!

Got the cupola glued in place, and started adding some details. Not sure what I'll do about the windows that face blocks (all those that you can see from this angle). I guess will paint them black to fake it, I definitely don't want any part in trying to cut through that whole block to make them pass through to the interior.

So far I think it looks pretty good, but now that I actually measure it the damn thing is about 13 scale feet tall