Doc

Rivarossi Doc

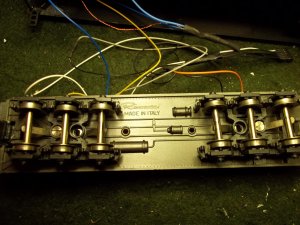

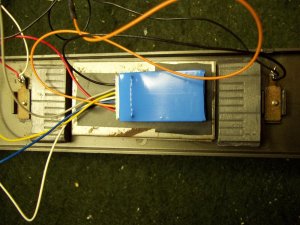

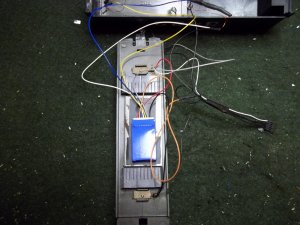

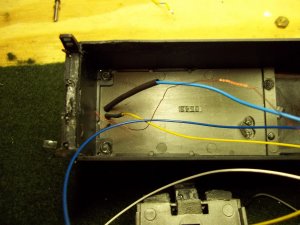

Greetings All, This is the first in a fleet of old Rivarossi's that I hope to convert to DCC. I used a non sound Digitrax DH123D decoder as I wanted to test the waters on a simpler level than sound. It might be noted that I was installing a Digitrax SCFXD radio dcc starter set at the same time. Help here on the Forum said to make sure to Isolate the loco motor, add pickups for the loco and modify the tender for dual rail pickups as well. So here is the loco modifications.

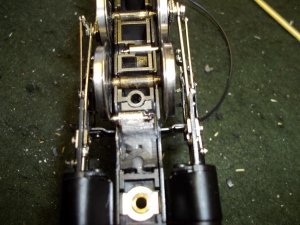

From some old Rivarossi parts I used a spring wiper and plastic mount frame.

I cut and modified the mount frame to fit in the front of the loco and soldered a lead to the back of the spring housing.

After drilling a hole for the lead I assembled the pickup.

With the front drive wheel removed and some of the metal frame modified I was able to install the new pickup. An additional hole was required to feed the with through the metal frame. This now gave the loco a left rail pickup as all the original pickups ( 2 ) were on the right rail.

Next post the results.

From some old Rivarossi parts I used a spring wiper and plastic mount frame.

I cut and modified the mount frame to fit in the front of the loco and soldered a lead to the back of the spring housing.

After drilling a hole for the lead I assembled the pickup.

With the front drive wheel removed and some of the metal frame modified I was able to install the new pickup. An additional hole was required to feed the with through the metal frame. This now gave the loco a left rail pickup as all the original pickups ( 2 ) were on the right rail.

Next post the results.