Progress from the layout.

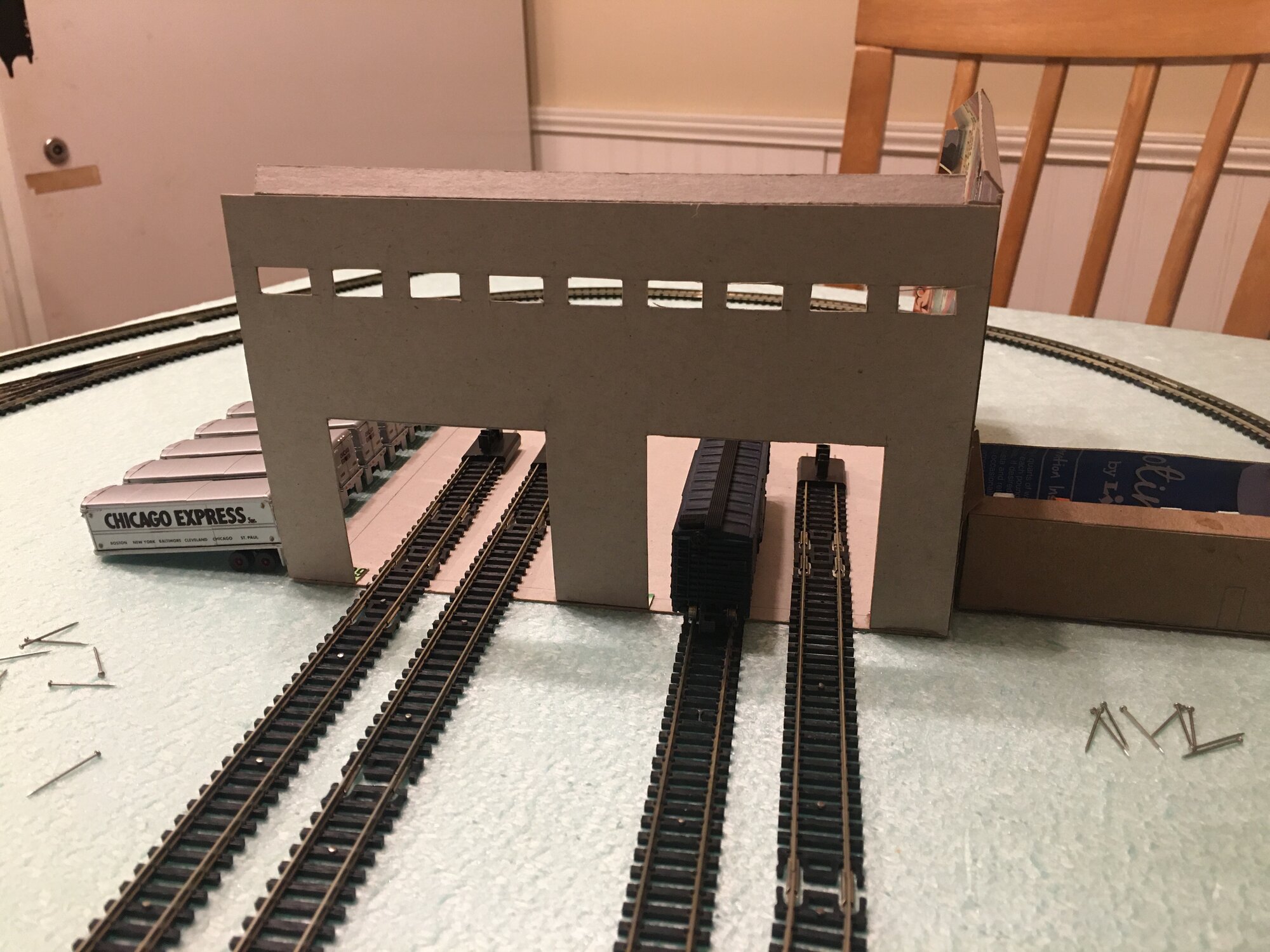

After track issues were sorted out, planning began for the NHRR transfer depot. Freight from all over the south will transition from rail to truck through this building. Here is the basic concept:

Freight cars enter on the left, trucks exit on the right. The small rectangle on the bottom will be the office, while the top side represents trailer storage.

There is space for 9 trailer awaiting loading. There will also be parking for a yard truck as well. I am considering adding another turnout to the lower line so that I can station a small switching engine on sight for switching operations.

The facility can support up to 4 railcars at once. Plans are to add roadbed and then sink the rails into the floor of the depot as well as building a loading dock that will service all 4 cars at once and also to cover over the bump stops to provide a seamless appearance. I am considering adding crane rigging to the ceiling area to aid in freight transfer as well as an exterior dock for flatcar loads. I have thought about tank car transfers as well, but I don't know if that will come to fruition. That may be a separate facility, possibly on the second sidings or at an as yet acquired piece of real estate. The main purpose of the trucking division of the NHRR is to service the textile industry and the town's needs, but it may expand to become it's own entity.

There are also plans to build doors that will swing over the rails to allow the building to be closed up if ever needed. I have not yet decide if these will be functional or simply for decoration.

Yes, the track is kinked in this photo, but it was just pulled up to allow test fitting of the building. That will be corrected upon final installation.

This is the current office space, subject to future expansion. The roof will be added after interior detailing (if any) and the parking lot will be painted in the space occupied by the service truck. There will also be a storage area added behind the office. Eventually there will be rail crossings to aid in accessing the outside world, but for now everything will be confined to the available space.

I am considering wrapping the entire exterior with styrene brick sheets and detailing with depend on what is available that suits this application. Stay tuned for further updates, hopefully to include videos of trains running.