NYC_George

Well-Known Member

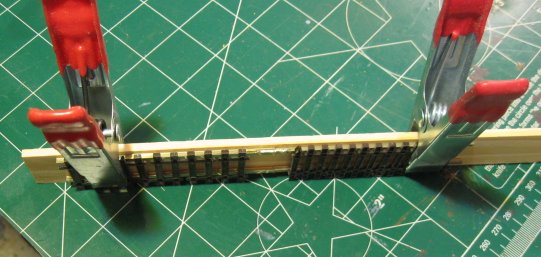

I started my layout 22 years ago when code 100 was in big use. Now that I use nothing but code 83 I found the need for some code 100 to code 83 transitions tracks. They run about $12.00 so I decided to make my own. It only takes about 10 minutes to create one so below are some photos to show you how.

You'll need a small gauge solid copper rod, a paint stirring stick, a few clamps, solder, and small file.

1. Clamp the code 100 and code 83 track to the paint stick with the top of the rail facing the stick.

2. Cut a small piece of rod about the same length as a rail joiner then place it on the 2 rails.

3. Solder the the tracks and rod together.

4. Turn the track over and file down any excess solder that may found it's way to the bottom of the rails.

5. Make a tie that fits snuggly under the code 83 track.

It's done.

You'll need a small gauge solid copper rod, a paint stirring stick, a few clamps, solder, and small file.

1. Clamp the code 100 and code 83 track to the paint stick with the top of the rail facing the stick.

2. Cut a small piece of rod about the same length as a rail joiner then place it on the 2 rails.

3. Solder the the tracks and rod together.

4. Turn the track over and file down any excess solder that may found it's way to the bottom of the rails.

5. Make a tie that fits snuggly under the code 83 track.

It's done.