KB02

Well-Known Member

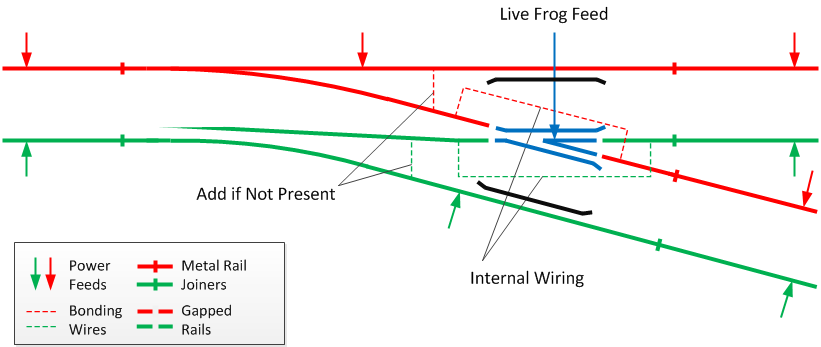

Thank you! I just downloaded an article that shows that and even mentioned that taking a Peco turnout right out of the box and installing it will guarantee a short. I'll insulate the 3 turnouts I have so far and others down the line. Will post the results.

It will be interesting to see if this ended up being the problem. Sounds like it could be. I eventually got around my shorting issues by running all power through a Tam Valley booster. It acts as a circuit breaker as well and handles the tiny shorts before they even get to the command station. Makes my layout much more controllable.