CMMR

Member

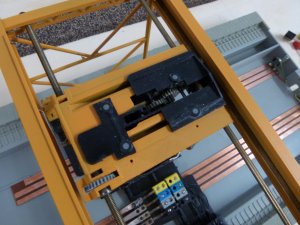

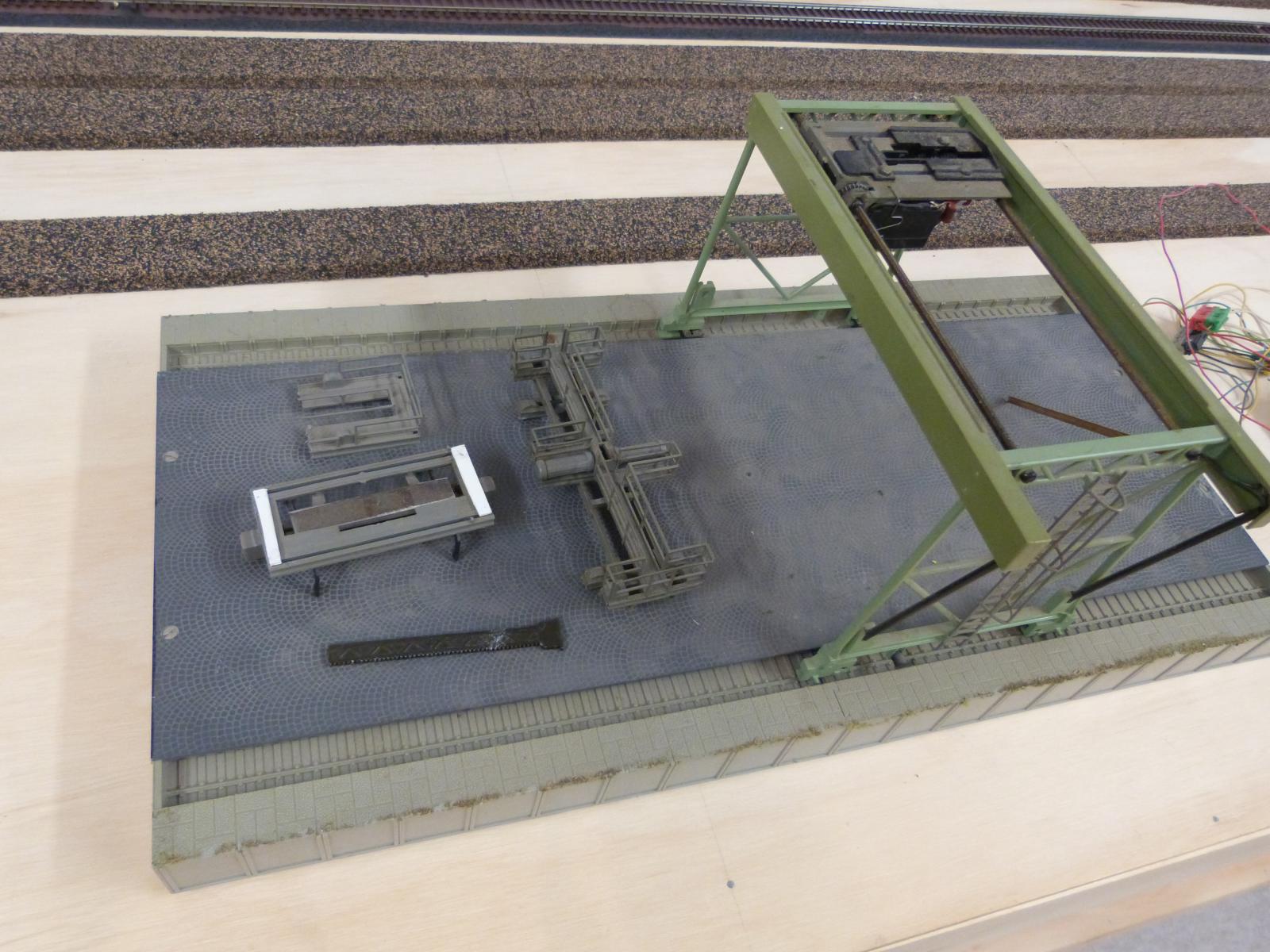

Ever since I saw the Heljan container terminal for the first time I thought it would be a great addition to my layout. Unfortunately, every one for sale that I have come across has gone for stupid money.

I thought a good compromise would be the Brawa version. While not as cool as the Heljan, it is still motorized, and a little more compact. The thing is these have started to go up in value as well. When you factor in the fact that I live in Canada and our dollar has tanked lately compared to the US greenback, I didn't think it was going to be possible either.

Then one day I came across this one on Ebay. It was advertised as for repair or parts, but it had the controller. Also it was located in Canada, so shipping costs were reasonable as well. I bid a little above the starting bid, and fortunately there were only 3 bids, with mine being the highest.

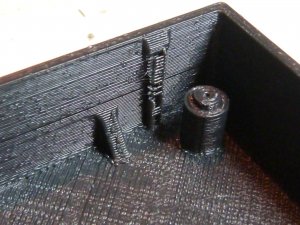

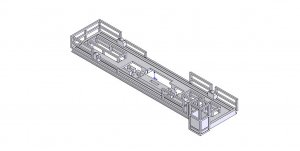

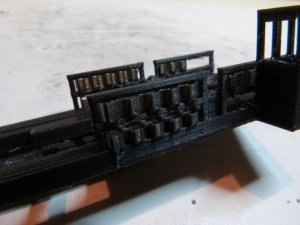

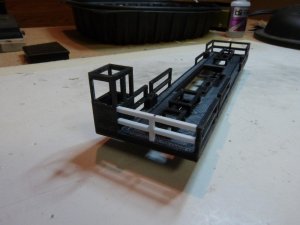

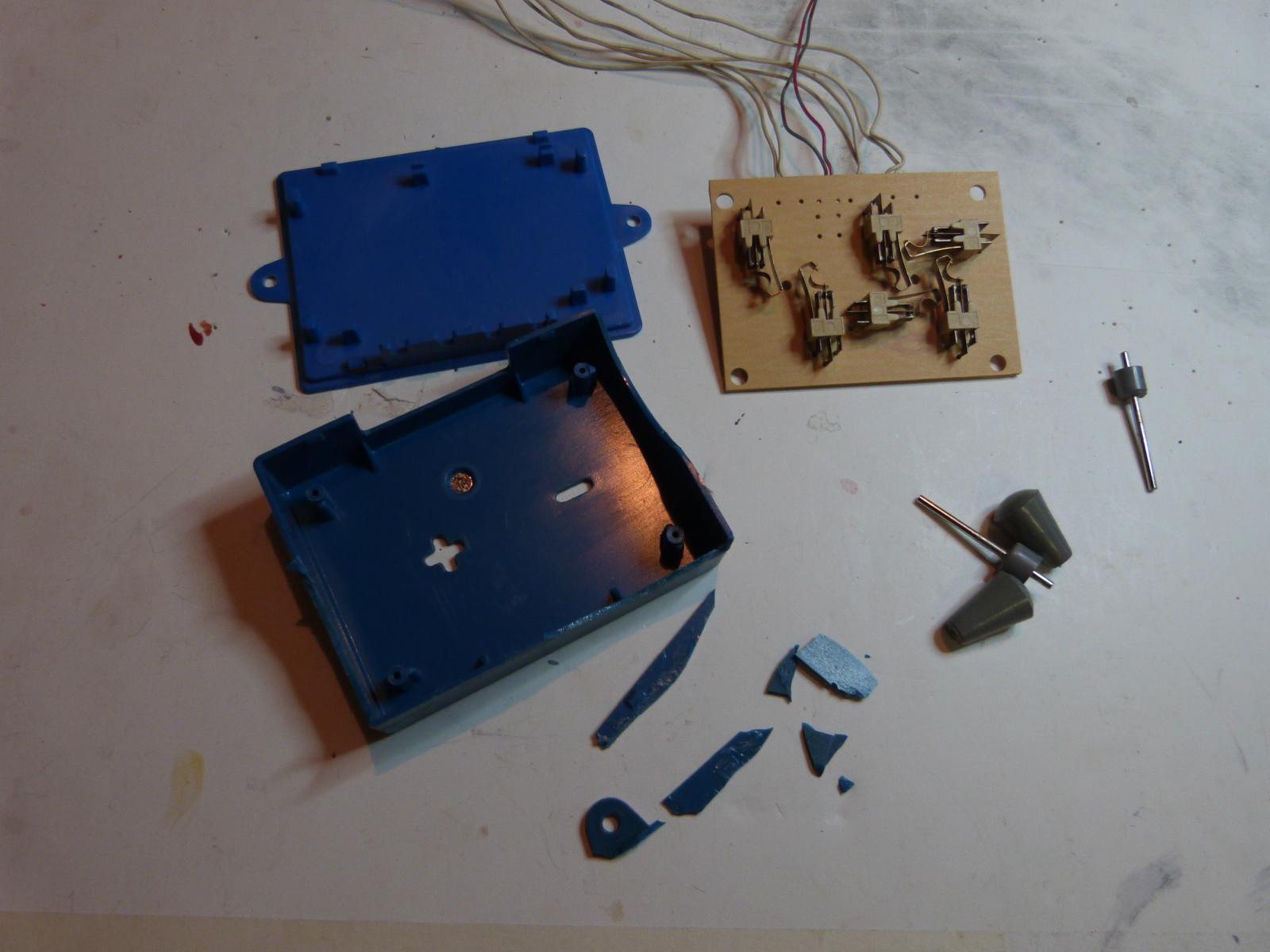

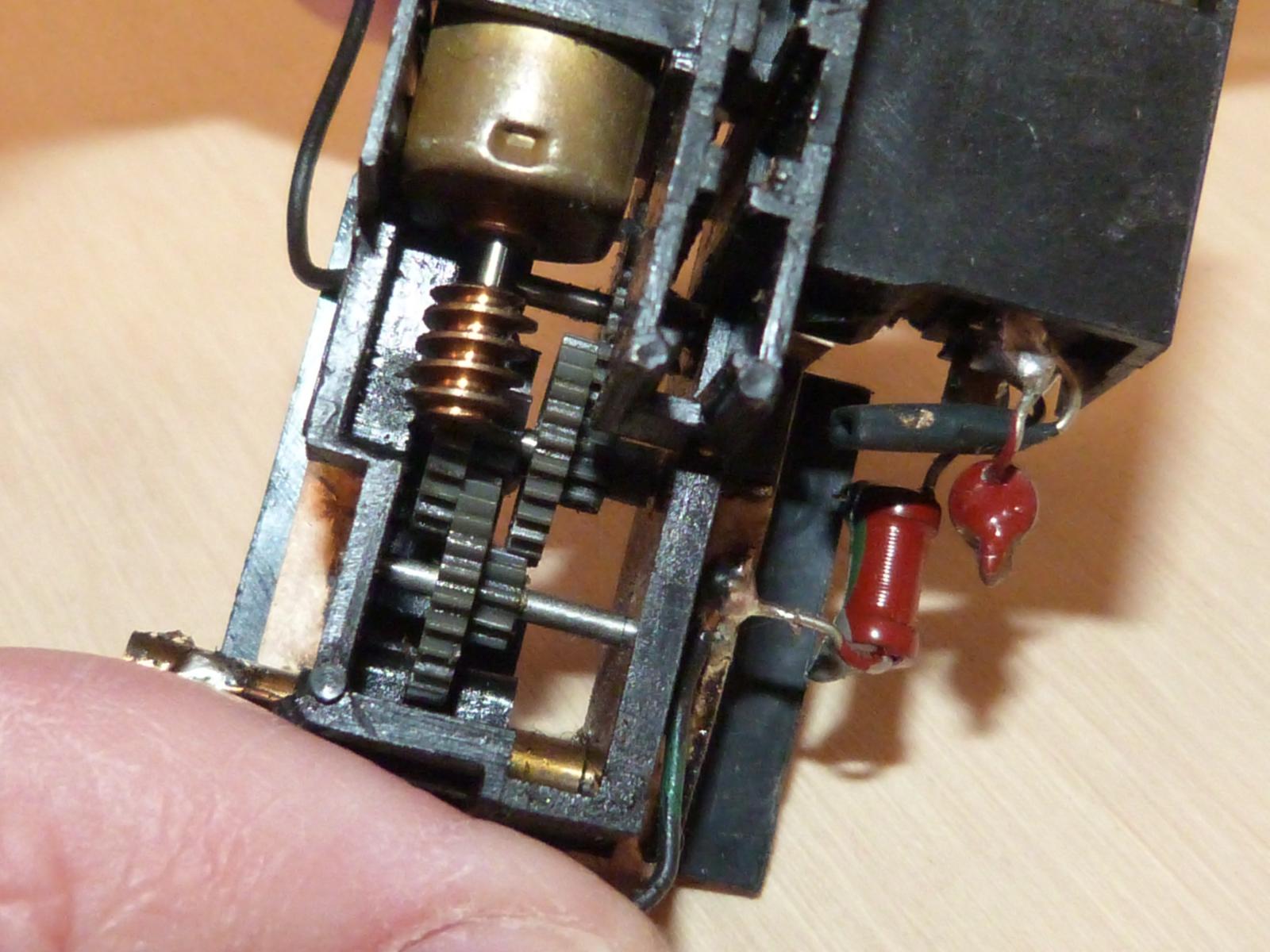

I just received it last week, and the seller wasn't kidding about the repair part. The lower platform is missing half, the upper platform has broken off, and one of the gears is definitely stripped. The controller box was being held together with electrical tape. and when I removed it half the cover came with it. On the plus side, all 3 motors appear to work.

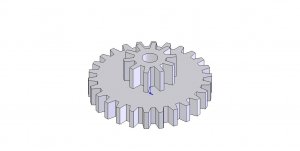

My plan is to restore this. One of my coworkers just purchased a 3D printer, so I am going to try and model all the broken parts in SolidWorks and get him to reproduce them.

Wish me luck!

I thought a good compromise would be the Brawa version. While not as cool as the Heljan, it is still motorized, and a little more compact. The thing is these have started to go up in value as well. When you factor in the fact that I live in Canada and our dollar has tanked lately compared to the US greenback, I didn't think it was going to be possible either.

Then one day I came across this one on Ebay. It was advertised as for repair or parts, but it had the controller. Also it was located in Canada, so shipping costs were reasonable as well. I bid a little above the starting bid, and fortunately there were only 3 bids, with mine being the highest.

I just received it last week, and the seller wasn't kidding about the repair part. The lower platform is missing half, the upper platform has broken off, and one of the gears is definitely stripped. The controller box was being held together with electrical tape. and when I removed it half the cover came with it. On the plus side, all 3 motors appear to work.

My plan is to restore this. One of my coworkers just purchased a 3D printer, so I am going to try and model all the broken parts in SolidWorks and get him to reproduce them.

Wish me luck!

Last edited by a moderator: