Engauge18

New Member

Hello all,

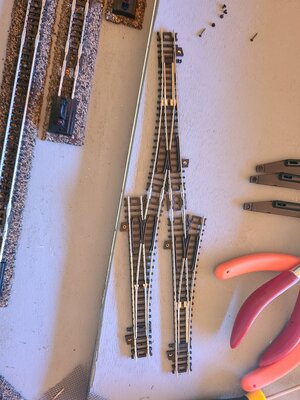

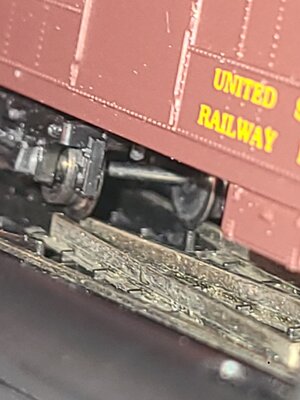

Has anyone else experienced problems with atlas standard switches?

My layout calls for 21 switches. Four of these things had issues - its a of the plastic part is too high and the train wheels jump at a specific point in the rail.

I tried shaving it down with an exacto knife but that didn't help.

I bought three more and one of them had the same issue.

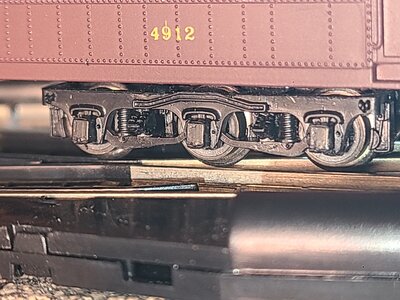

It's like the plastic part of the switch is too shallow for the wheels of the cars.

Have two more on order. Fingers crossed one of them is OK.

Has anyone else experienced problems with atlas standard switches?

My layout calls for 21 switches. Four of these things had issues - its a of the plastic part is too high and the train wheels jump at a specific point in the rail.

I tried shaving it down with an exacto knife but that didn't help.

I bought three more and one of them had the same issue.

It's like the plastic part of the switch is too shallow for the wheels of the cars.

Have two more on order. Fingers crossed one of them is OK.