eTraxx

Member

I had ordered a 'grab bag' from Tichy and one of the items included was a styrene 55-gal barrel in O scale. I was looking at it the other day .. and it occured to me that I might be able to use it to make some more from aluminum foil.

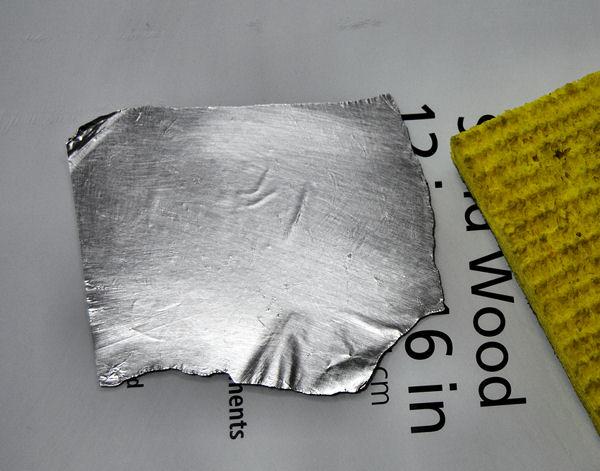

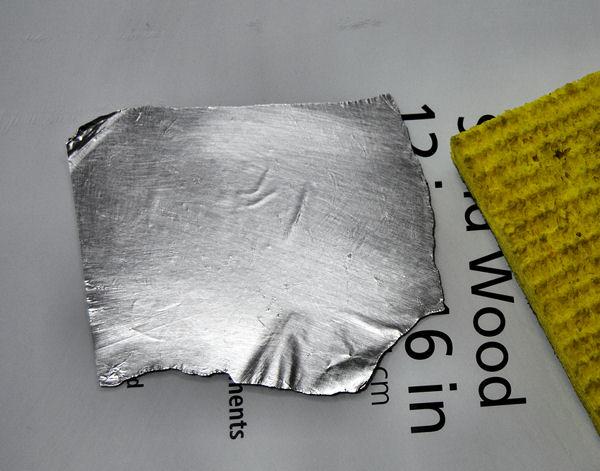

1) I took some 'Heavy Duty' (whatever that is supposed to mean) aluminum foil. I laid it on a glass surface and used a green scrubby and Windex to remove the oils (edible) that is on the foil. This not only cleans the foil but helps flatten it.

2) The Tichy barrel measures 3/4" tall so I cut a strip that wide.

3) Here's the Tichy barrel. It's actually pretty in scale .. just not beat up enough.

4) Wrap the foil strip around the barrel and cut to a length so it wraps completely around.

5) Here we go ..

6) Use your thumb and press the foil against the styrene barrel so you get the ribs show through

7) Now, you have a barrel wrapper ...

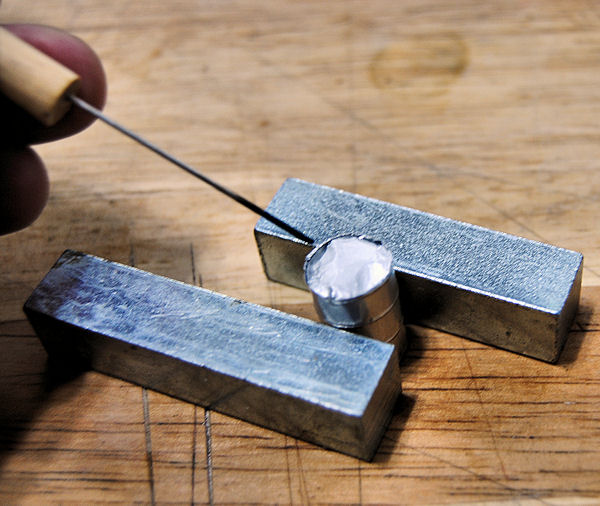

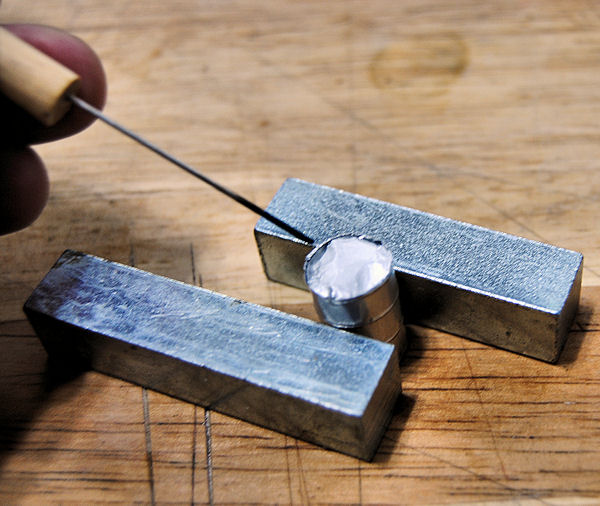

8) I have these two pieces of 1/2" keystock that I picked up at Ace Hardware. Excellent for a small weight to hold things. The barrel is so light and delicate that a puff of air will send it flying. I set it against one of the keys and slowly and gently slide the other up against the sleeve .. a little adjustment aligns the edges of the foil/ribs. Here, I'm applying a thin super glue (M5T) to the joint. The tool you see is my super glue applicator .. simply a large needle with the eye cut in half. Works great for precision application of the glue.

9) Use the Tichy barrle to mark the foil. This will be the bottom of your barrel. I used some small nail scissors to cut it out.

10) Super glue the bottom to the shell. I started with the barrel laying on it's side between the keys and glued at only one point. Let that set up .. rotated the barrel and prodded the bottom until it aligned with the sides. Kept doing that. Not perfect but then I wasn't intending to display the bottom of this anyway so .. good nuff.

11) The Tichy barrel is on the left. Center is the first barrel. It's just a tad large .. but .. hey .. was my first try and looks fine if not sitting next to the Tichy. I sprayed it with some gray primer and then dunked it in my grungy solution (black and brown india ink, black shoe dye, tie brown acrylic and lots of alcohol). The one on the right is the one I made for this tutorial. It's been dipped in aluminum blackening and then brushed with a brown paint and finally dipped in the grungy solution.

1) I took some 'Heavy Duty' (whatever that is supposed to mean) aluminum foil. I laid it on a glass surface and used a green scrubby and Windex to remove the oils (edible) that is on the foil. This not only cleans the foil but helps flatten it.

2) The Tichy barrel measures 3/4" tall so I cut a strip that wide.

3) Here's the Tichy barrel. It's actually pretty in scale .. just not beat up enough.

4) Wrap the foil strip around the barrel and cut to a length so it wraps completely around.

5) Here we go ..

6) Use your thumb and press the foil against the styrene barrel so you get the ribs show through

7) Now, you have a barrel wrapper ...

8) I have these two pieces of 1/2" keystock that I picked up at Ace Hardware. Excellent for a small weight to hold things. The barrel is so light and delicate that a puff of air will send it flying. I set it against one of the keys and slowly and gently slide the other up against the sleeve .. a little adjustment aligns the edges of the foil/ribs. Here, I'm applying a thin super glue (M5T) to the joint. The tool you see is my super glue applicator .. simply a large needle with the eye cut in half. Works great for precision application of the glue.

9) Use the Tichy barrle to mark the foil. This will be the bottom of your barrel. I used some small nail scissors to cut it out.

10) Super glue the bottom to the shell. I started with the barrel laying on it's side between the keys and glued at only one point. Let that set up .. rotated the barrel and prodded the bottom until it aligned with the sides. Kept doing that. Not perfect but then I wasn't intending to display the bottom of this anyway so .. good nuff.

11) The Tichy barrel is on the left. Center is the first barrel. It's just a tad large .. but .. hey .. was my first try and looks fine if not sitting next to the Tichy. I sprayed it with some gray primer and then dunked it in my grungy solution (black and brown india ink, black shoe dye, tie brown acrylic and lots of alcohol). The one on the right is the one I made for this tutorial. It's been dipped in aluminum blackening and then brushed with a brown paint and finally dipped in the grungy solution.