I've used my FDM 3d printer for locos in the recent past, but I just started doing buildings and other details and I'm hooked on these, too.

Here are a few of the details I'm working on, so you can see what they look like, plus some closer shots. Like the two desks/chairs (I started doing furniture a few days ago):

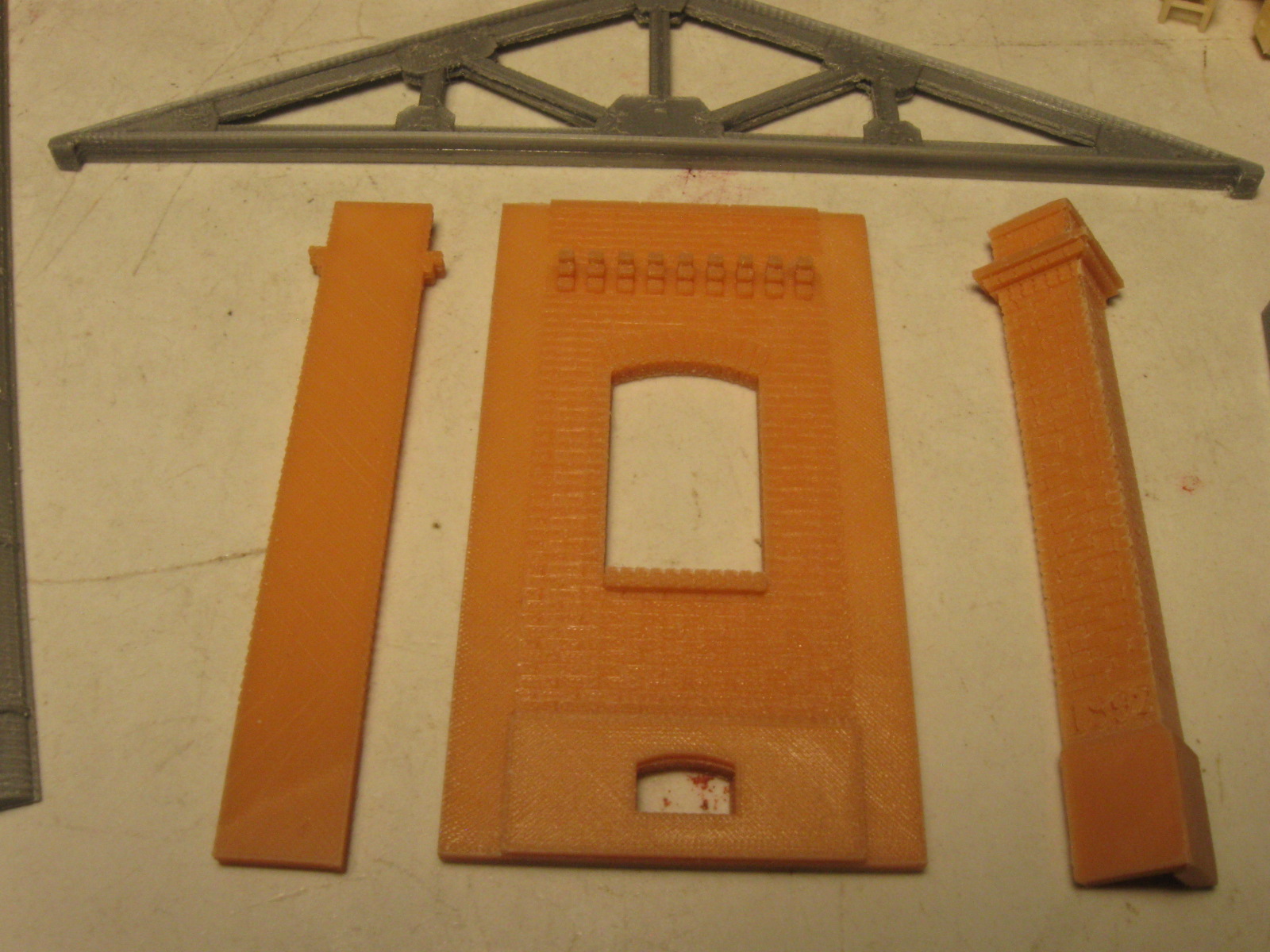

These are HO scale. (One's in oak; the other in pine.) Also you can see a close-up detail of a roof truss for a building that's going to be entirely 3d printed. (I like rivets, too, twforeman. And your tower is awesome!) Also a roof ventilator. And as twforeman stated, it helps if you know CAD. These were done on AutoCAD, which I actually like better than Fusion360. I'm old-school engineer; started out drafting by hand but worked my way up to CAD.

Sofa, chair, coffee table, round table, also some rain gutter details (yes, it is hollow on the other side). It's 0.3 mm (0.012") thick, so if you're wondering how fine you can get, this is close to it. I'm not sure how much better you can get with resin printers. The final shot is of brick walls.

I didn't even realize it until after I 'developed' the picture that the column was showing the backside! Sorry. But at least you can see the brick detail on the others, and I really did model each of those bricks individually! The main wall section took exactly two hours to print, and I'm using 14 in the building. (I suppose I could do one and make a casting, but the backside also has details on it, and that would necessitate a two-part mold, so it was a toss-up.) Also, on the corner, there is a detail that is missing from most model buildings: the cornerstone, complete with the date 1892. That's one of the great things about 3d printing: you can customize so easily. The final walls were printed in concrete color, so all I have to do is paint the bricks.

Okay, that's my two-cents worth. I love my printer(s) and can no longer live without it. It is the best thing that ever happened to my modeling skills. Now that I'm a senior and my eyesight (and arthritis) makes me physically challenged to do tiny things, it has opened up a whole world of possibilities that I never dreamed of.