OWilks1

New Member

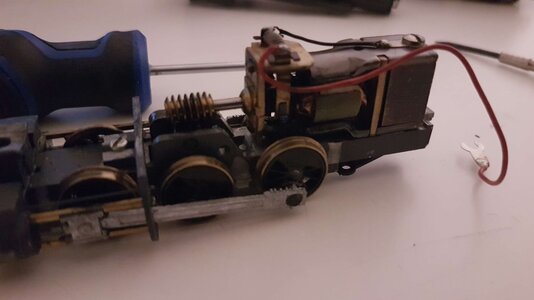

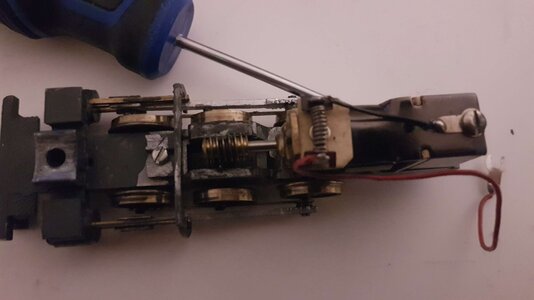

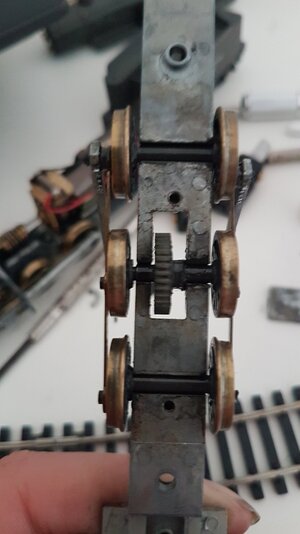

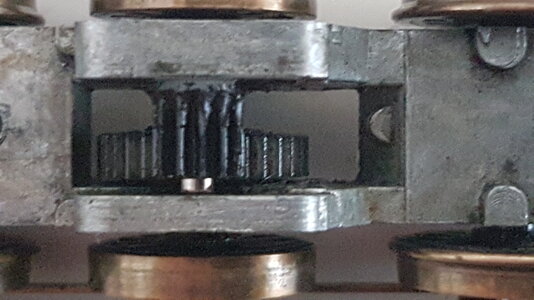

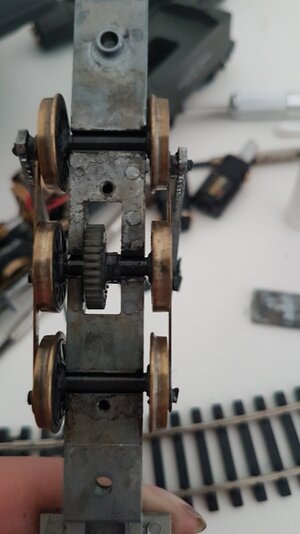

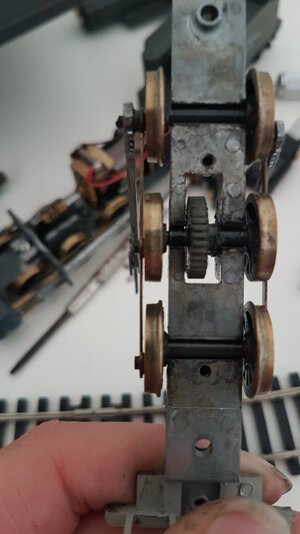

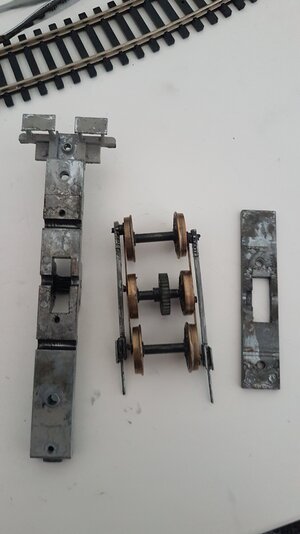

Hi all, first post here. Just working on 2 supposed roundhouse tender 0-6-0's and they both short circuit when running for a tiny bit. One of them also has a motor that will stall and only run for a tiny bit if i give it a little spin myself. While stalled, the motor starts to get really hot as well. Would anyone be able to give me any help on how to solve these problems?

Cheers, Wilks

Cheers, Wilks