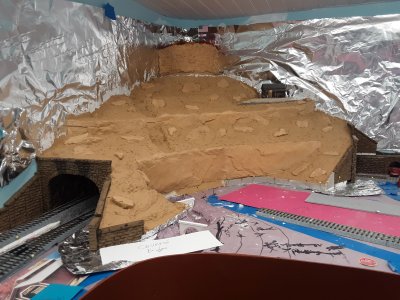

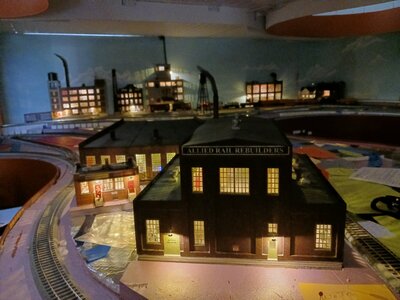

Finally getting some time to submit anew post. This one is about the mountain I have added to my layout. The mountain is in a corner of my layout, kinda like an anchor! Theidea is for the flat landscape and parallel tracks to lead the eye tothe mountain. Two mainline tracks go through tunnels. Both mainlinesenter the tunnels on the same level but one line climbs a gradeinside tunnel so at the other end they are at different levels. Infront of the mountain will be the Champion Packing Plant by Walthers.

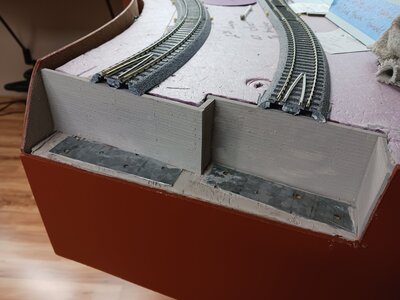

I started with making the tunnels,using a sheet of one inch foam for the ceiling. I had some flexible3/8” foam laying around which I used for the walls of the tunnels. I used some techniques for the tunnels I saw on a YouTube video doneby a young guy in South Africa named Gerben. He has some videos onYouTube under “ThecreativemodellerHO. His method of lining thetunnels with crumpled craft paper makes for realistic tunnel rockwalls. I used spray paint to color the tunnel walls.

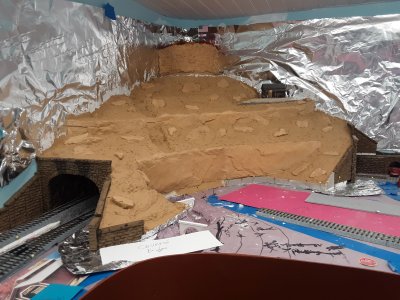

I then built the mountain using layersof scrap pieces of 1 inch thick foam, held in place with constructionadhesive. I then covered the foam with home-made sculptamold. Iused Gerben's method of making sculptamold from egg cartons processedthrough a blender to shred them, and then I mixed it with Easy Sand90 minute drywall joint compound available at Home Depot and Lowes. This works well, it gives a 90 minute working time so I don't have torush when using it, plenty of time to get the terrain shape justright before it sets up.

The mountain design is taken fromCastle Rock in Colorado. I also use Castle Rock as the name of thelittle town on my layout. My two mainlines are the Denver & RioGrande Western, and the Atchison, Topeka and Santa Fe. HistoricallyCastle Rock Colorado was served by both of these railroads, thus thereason for the Castle Rock town and the Castle Rock mountain on mylayout. Of course I have taken great liberties with both so neitheris accurately modeled correct to reality. Two things that areaccurate is the American flag flying 24/7 and lit at night, and ahiking trail to the top of Castle Rock. The landscape includes tallpines, some different varieties of oak, aspen, grasses, briars, andlow evergreen scrub. It is fall season so the oaks and aspen areshowing fall colors.

I built the top of the mountain using aone gallon plastic paint container cut down to the right height. Ithen glued flexible rock castings on this container, leaving the endsfanning out so they meet the backdrop at the right angles. I alsoglued plaster rock castings on the top and then landscaped the top. Afew trees on top have been killed by lightning strikes. In additionto the flags, there are radio and tv broadcast towers.