OK... Deep breath...

Let me preface this with the following. It's your railroad, do whatever you want to do. You can choose to install something just because it's cool, you like it, or just because you want to.

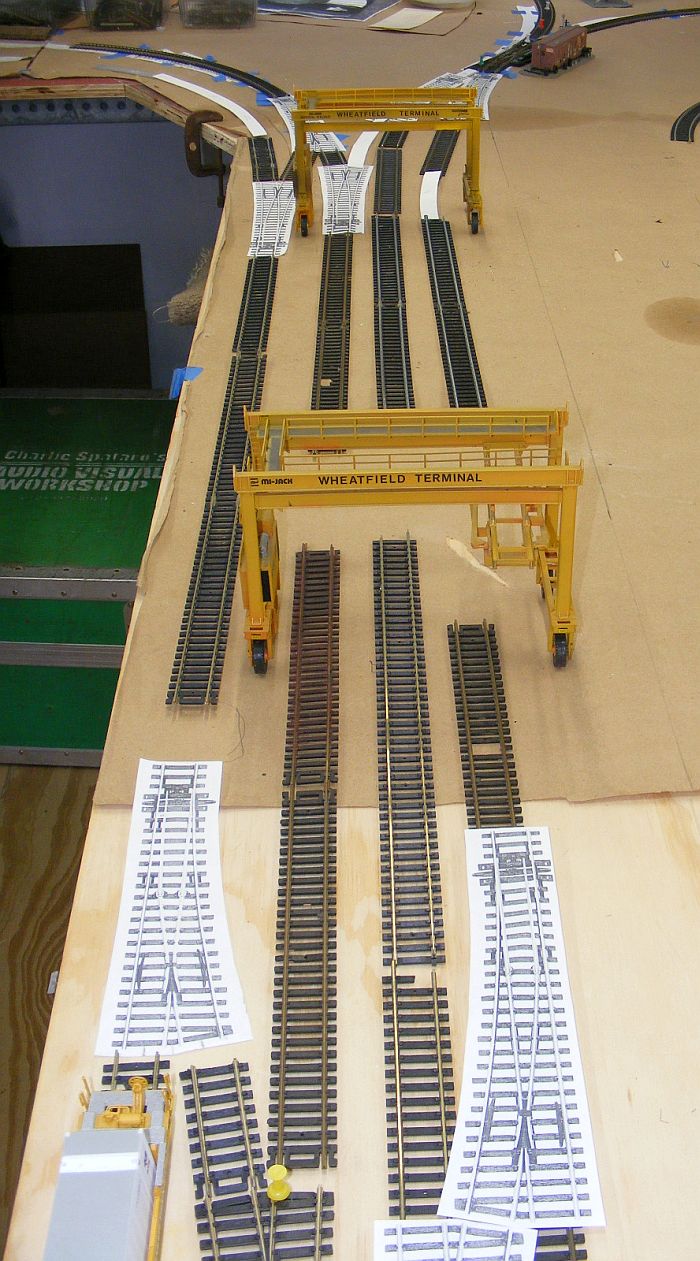

That said, I can tell you that I have 30 years experience building container yards. Mine are in 12" to the foot scale. Port of Tacoma, Port of Seattle, Port of Tacoma. I've been project engineer on container terminals at all of them.

That said, a couple of comments.

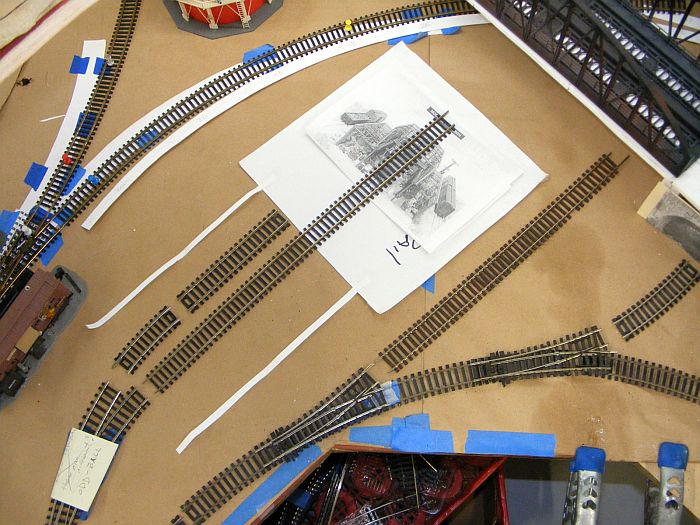

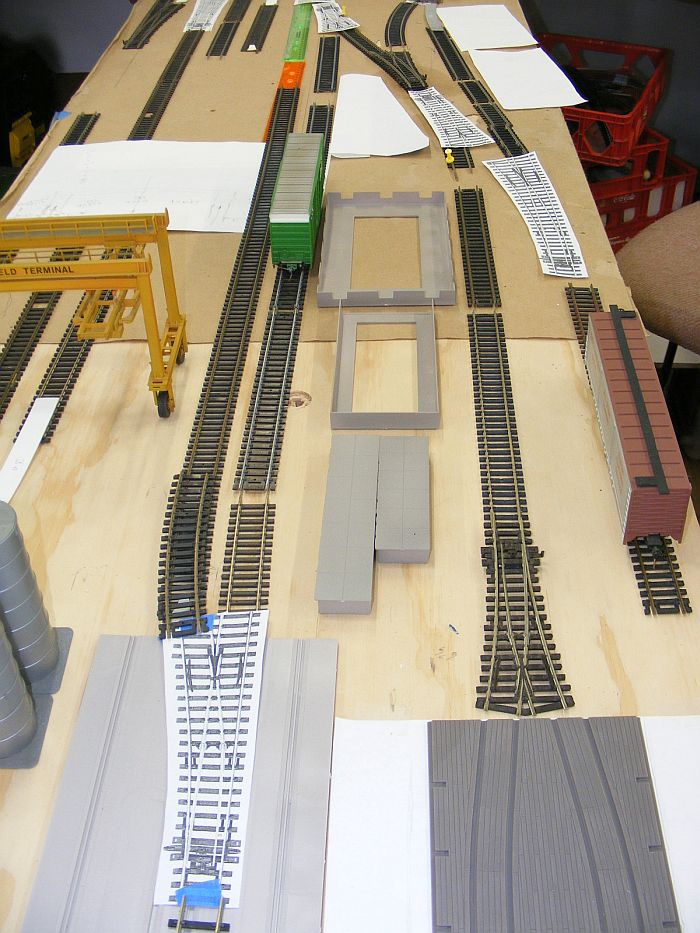

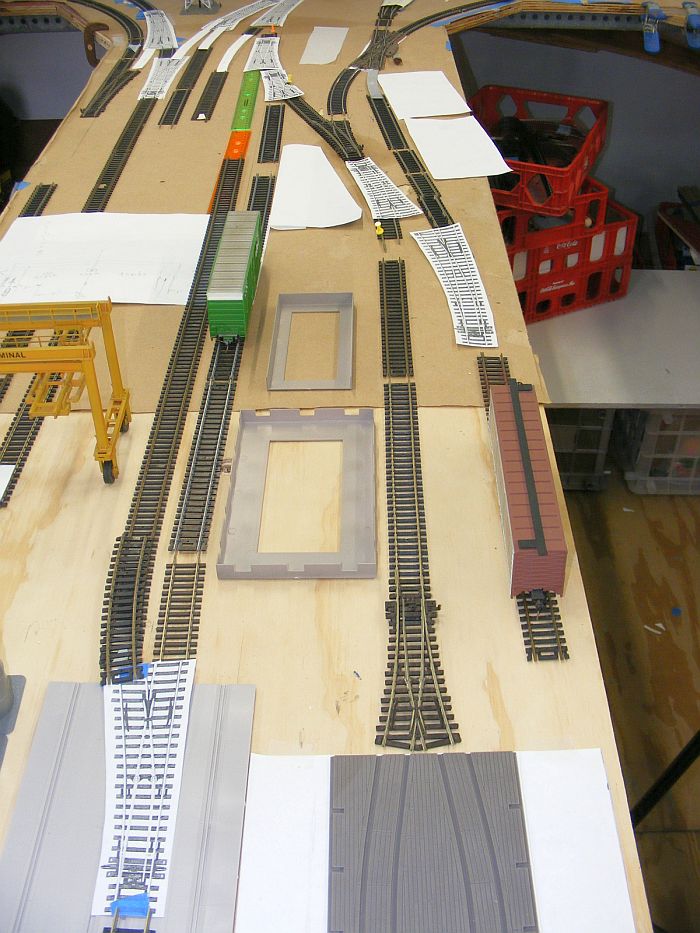

1) A lot of container terminals, (but not all) simply don't have escape tracks. They take up valuable space and turnouts are expensive, as in $50,000 each and up. So they just use stub tracks and shove the cars in. Problem solved, and you have more room for cars.

2) Even when a container terminal has an escape track, they don't have double slip switches. Double slip switches on the prototype are extremely rare. They're normally only used in passenger stations and other areas with limited space and lots of traffic. They ridiculously expensive and challenging to maintain. I have never installed a real one. I've never even bid on a project that had one. In fact, I have rarely ever even seen one of them. There's some in Chicago at Union Station, maybe LA on the passenger lines, and possibly other big city terminals that I'm overlooking. They were more (slightly) common on the east coast. But outside of busy passenger terminals, they're rare indeed.

That said, IF the civil engineer who designed this project actually called for that, I would go to the owner with a Value Engineering Change Proposal (you save them money and get a small percentage of the savings as reward) and I'd say "How about I save you a 1/2 million dollars and years of maintenance headaches, whaddya think?" Two of them in one terminal? Sorry, but that's never been done. In fact, I’m almost sure one has never been done. Maybe, but really doubt it. I rarely say "never" as it seems you can find dang near anything. But I'll make an exception in this case. The cost simply couldn't be justified.

The same for that crossover 2 car lengths from the switch. That costs about $100K and it serves no real purpose. It simply wouldn't be there.