Center Peninsula Track Planning, …..Container Terminal & Port Facility

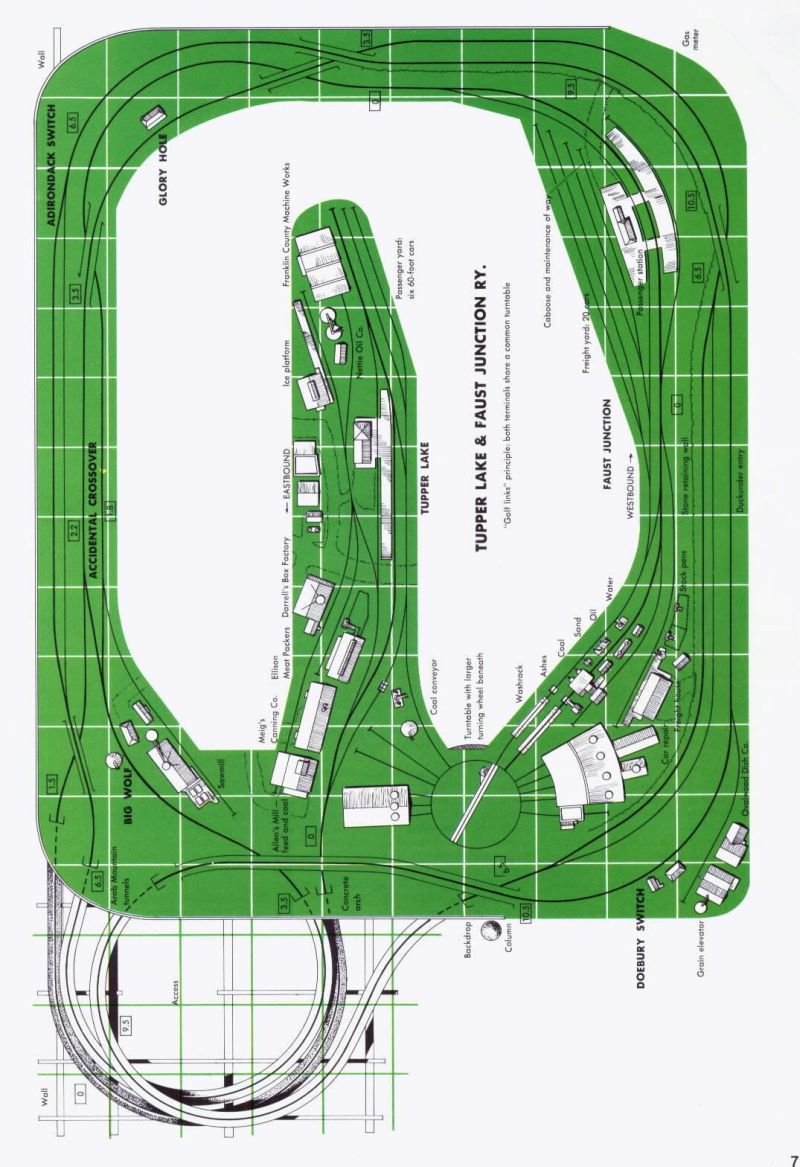

I've been putting this off too long. This is the original Tupper Lake/Faust Junction peninsula track plan I was using as inspiration.

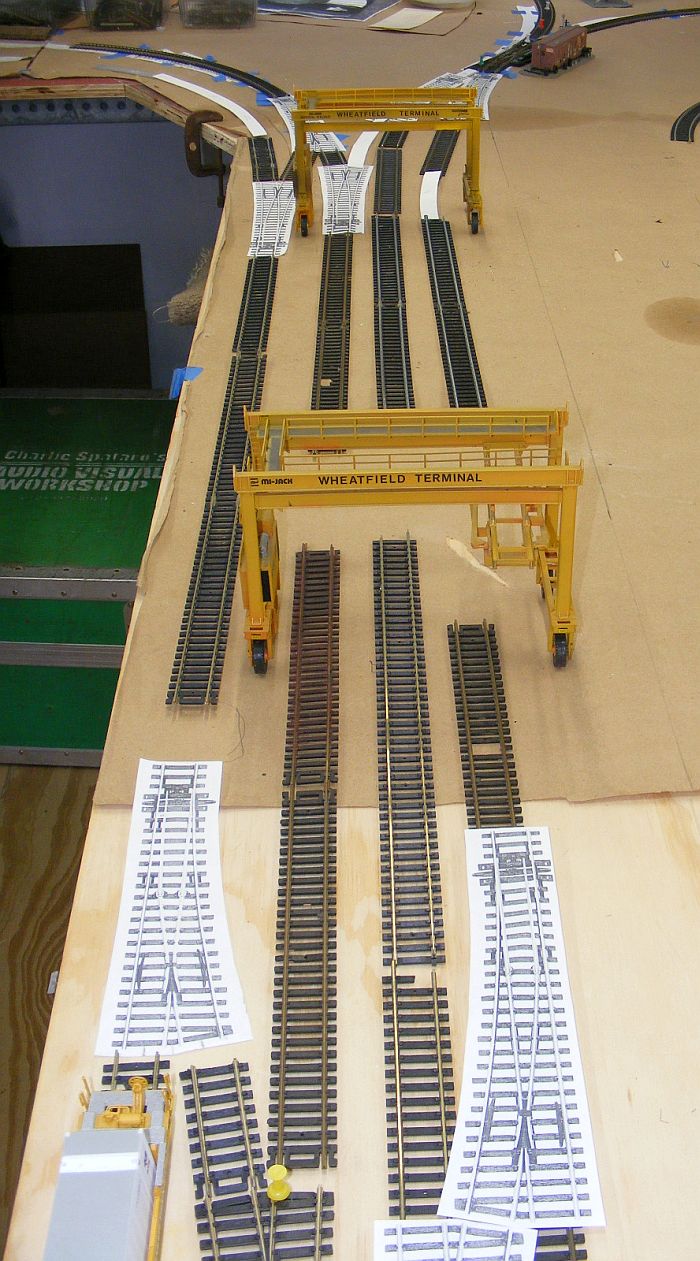

That plan had a passenger train station in the peninsula area. My new plan is going to be much more 'industrialized' , and that station location is now becoming a container terminal zone.

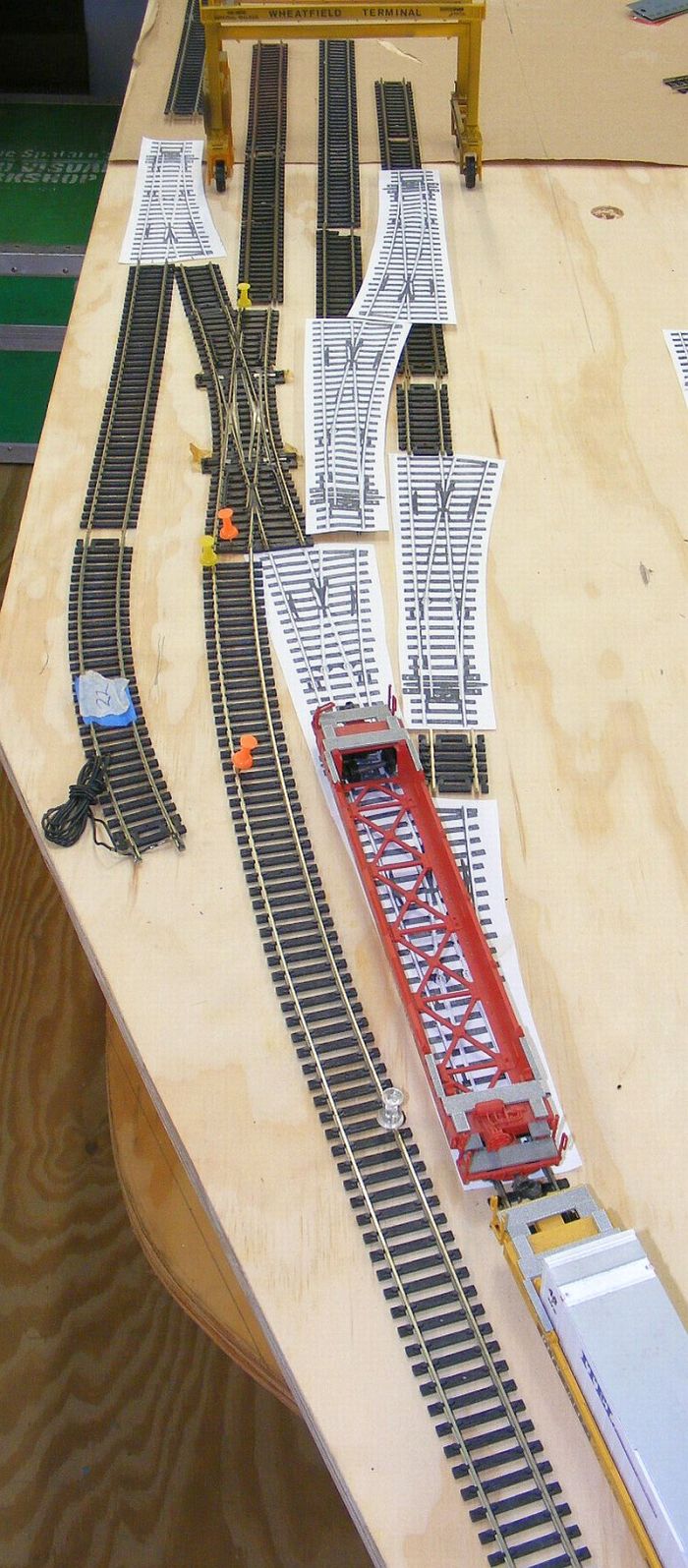

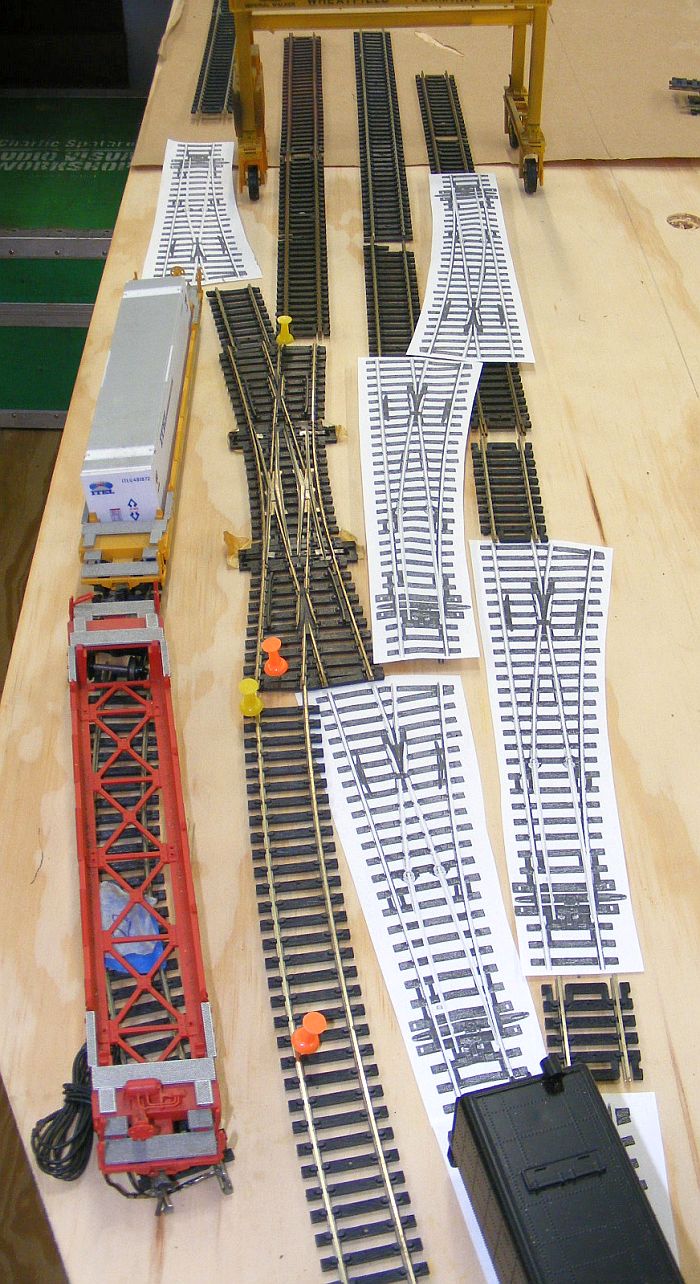

By happenstance I ran across a carfloat model at our local flea market. What if I were to put that out on the end of my peninsula, across from my other waterfront scene? ...another tug boat, barge item....becoming a port facility .

So this discussion of a track plan for the peninsula is going to consider these 2 elements as sub-subjects,...container terminal & port facility.

What I am going to need help with is how to make these two sub-scenes operational...how to move/switch cars around in them?

I don't yet understand the intricacies of switching.

I've been putting this off too long. This is the original Tupper Lake/Faust Junction peninsula track plan I was using as inspiration.

That plan had a passenger train station in the peninsula area. My new plan is going to be much more 'industrialized' , and that station location is now becoming a container terminal zone.

By happenstance I ran across a carfloat model at our local flea market. What if I were to put that out on the end of my peninsula, across from my other waterfront scene? ...another tug boat, barge item....becoming a port facility .

So this discussion of a track plan for the peninsula is going to consider these 2 elements as sub-subjects,...container terminal & port facility.

What I am going to need help with is how to make these two sub-scenes operational...how to move/switch cars around in them?

I don't yet understand the intricacies of switching.

Last edited by a moderator: